Table of Contents

|

In the demanding world of industrial processing, standard off-the-shelf components often fall short when faced with extreme operational challenges. This case study highlights how JRVAL, a leading china butterfly valve manufacturer, transcended the role of a typical butterfly valve supplier to become a crucial problem-solving partner. |

|

⊙ Part I: The Challenge: A Chemical Plant's Triple Threat in Extreme Cold |

|

A large chemical enterprise in Northern China faced a critical upgrade project for a liquefied hydrocarbon pipeline. The plant's winter ambient temperatures frequently drop below -35°C, with extremes reaching -40°C. Their automation project hit a wall due to three complex issues:

• Low-Temperature Brittleness Risk: Standard carbon steel butterfly valve products pose a severe safety hazard due to low-temperature embrittlement. A catastrophic valve body fracture was a real and unacceptable risk. The need was for a specialized cryogenic butterfly valve or low temperature butterfly valve.

• Non-Standard Pipeline Connections: The legacy pipeline, built in the 1990s, had non-standard flange-to-flange distances (valve structural length) that were narrower than current national standards. A standard flange butterfly valve would require costly and risky pipeline cutting and re-welding.

• Specified Actuator Mismatch: The client mandated a specific imported pneumatic butterfly valve actuator for maintenance uniformity. However, its ISO 5211 mounting flange did not align with the top mounting platforms of conventional butterfly valves, necessitating an extra adapter bracket which adds complexity and potential failure points.

The project team contacted several prominent manufacturers of butterfly valves, but the responses were disheartening. They could supply low-temperature valves but couldn't customize the body width or top mounting dimensions. The project stalled. |

|

|

|

⊙ Part II: JRVAL's Integrated Solution: The "One Valve Fits All" Approach |

|

After an extensive search, the project team found JRVAL. Our technical team reviewed the challenges and proposed a holistic, integrated customization plan that addressed every issue with a single, purpose-built valve solution. This is where JRVAL's in-house capabilities in valve machining and butterfly valve assembly make the difference. |

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining

Butterfly Valve Machining |

|

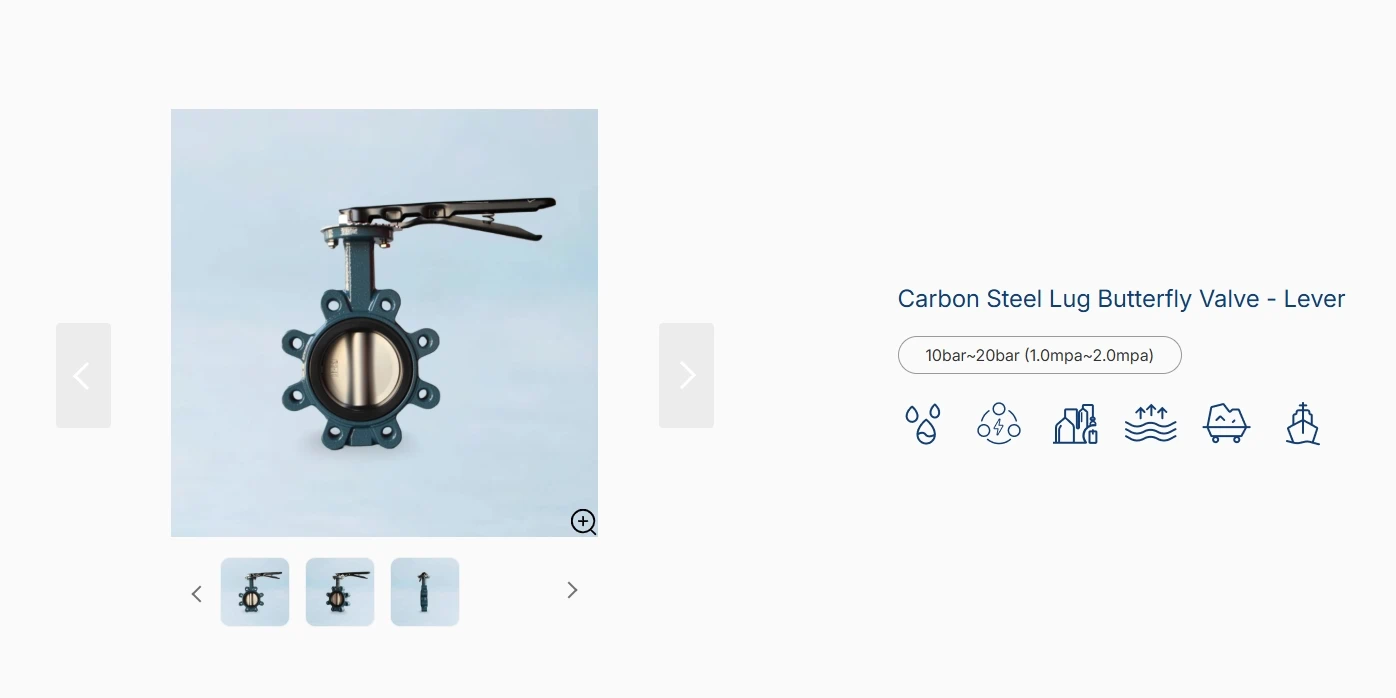

• Guaranteed Materials for Cryogenic Performance Instead of a standard product, we immediately recommended ASTM A352 LCB/LCC low-temperature carbon steel for the valve body and disc. This material, subjected to rigorous heat treatment, maintains excellent impact toughness and mechanical properties down to -46°C, easily exceeding the client’s -40°C safety requirement. JRVAL provided a full material test report (MTR) and product certificate, guaranteeing material integrity from the source. This is the quality assurance expected from a top-tier high performance butterfly valve manufacturer. |

|

• Heavy-Duty Body with Customizable Face-to-Face Dimensions Addressing the non-standard pipeline gap, we leveraged our flexible manufacturing. Our engineers took the client's precise "narrow-size" requirement and custom-produced a batch of lug type butterfly valve models with a structural length that perfectly matched the existing pipeline. Crucially, the valve body retained our signature heavy-duty, thick-walled design, meeting or exceeding chemical industry standards for pressure containment. This customization saved the client from the massive costs and delays of cutting, welding, and non-destructive testing, enabling a "seamless replacement" that drastically cut downtime. It was a perfect example of customized valve machining. |

|

• Direct-Mount Solution for Any Actuator For the actuator challenge, our engineers requested the technical drawings for the specified actuator. We then performed precision CNC butterfly valve machining on the top mounting platform and stem connection hole to match the actuator's ISO 5211 standard perfectly. The actuated butterfly valve arrived at the site as a "perfect match" for the client's equipment. Installation was a simple direct-mount process, eliminating the need for adapters, improving installation accuracy, maximizing transmission efficiency, and removing the risk of failure from loose brackets. |

|

|

|

|

⊙ Part III: The Outcome: A Triumph of Custom Engineering |

| Through our powerful customization capabilities and deep material expertise, JRVAL delivered a perfect, one-stop solution. We not only solved the critical safety issue of extreme cold but also saved the client significant costs and time by avoiding pipeline modifications and simplifying the automation process. In this case, the JRVAL butterfly valve was more than just a product. We acted as a technical partner, deeply understanding the client's pain points and delivering a precise, engineered solution. Whether the need is for a stainless steel butterfly valve, a high temperature butterfly valve, or a specialized triple eccentric butterfly valve, our unique approach sets us apart as a premier butterfly valve factory. |

|

Note on Materials: ASTM A352 Grade LCB is suitable for general low-temperature service down to -46°C [-50°F], while Grade LCC offers slightly improved weldability and toughness, also for service down to -46°C. The selection depends on specific application requirements and specifications like ASME valve or API 609 butterfly valve standards. JRVAL consults with clients to select the optimal material for every unique challenge. |

Need Help with Valve Selection?

We don't only sell generic valves. We provide engineered solutions tailored to the specific operating environment of your process area.

JRVAL

JRVAL Jul 09 2025

Jul 09 2025