Valve Body Casting

The material is controlled according to NASI standards (ASTM A182/A479 etc), and the tempering process enhances steel stability, making the valve unbreakable (+30% stress resistance).

Casting

Heat Treatment

Annealing

Quenching

High-temperature tempering

Water Cooling

Air Cooling

Trimming & Polishing

Cutting the pouring cap mouth

Polishing & sandblasting

Acid Pickling

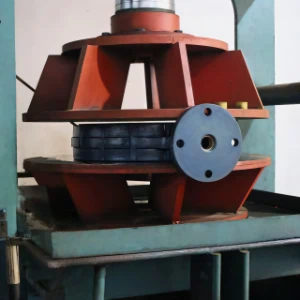

Valve Machining

JRVAL redesigned the fit of the body - disc- stem of valves. Through 18 CFD simulations, it is proved that the leakage is 0ppm under the bidirectional pressure of ±250bar.

Valve Body Deformation Adjustment

Processing Standards Confirmation

Process Quality Inspection

Precision-Built Durability

Tight tolerances ensure seamless component alignment, minimizing wear and maximizing cycle life. Discover how in our [Butterfly Valve Tolerance Table] below.

Valve Assembly

JRVAL employs premium components with rigorous quality control, verified by ISO 9001. Outstanding performance and service life are guaranteed by rigorous inspection at every stage.

Materials Parts Inspection

BOM Material Requisition

Epoxy Resin Coating

Pressure Testing

Packing with Non-Log Wooden Case

From Arctic chill of -50°C to desert heat of 160°C, from vacuum of 0.1bar to ultra-high pressure of 250bar,and to corrosive acid of ph=0.5, our valves redefine reliability. They are manufactured with a scientific material mix and precision engineering to provide unmatched performance even in harsh environments.