Maximum Security & Stability: Its double flanged body ensures a highly secure, bolted connection, making it ideal for high-pressure, large-diameter, and critical service applications.

Maximum Security & Stability: Its double flanged body ensures a highly secure, bolted connection, making it ideal for high-pressure, large-diameter, and critical service applications.

Superior for Demanding Service: The combination of a robust flanged connection and a dynamic dual-plate design makes it the preferred choice for pump/compressor discharge, end-of-line service, and systems where reliability is non-negotiable.

Superior for Demanding Service: The combination of a robust flanged connection and a dynamic dual-plate design makes it the preferred choice for pump/compressor discharge, end-of-line service, and systems where reliability is non-negotiable.

Design and Manufacture: API 609, ASME B16.34, ASME Section VIII

Side Flange Standards: ASME / ANSI: Class 125LB & 150LB; EN / DIN: PN6, PN10, PN16; BS / AS: BS 10 Table D/E, AS 2129 Table D/E; JIS: 5K, 10K (JIS B2220); GB / HG/T / GOST

Face-to-Face Dimension: API 609, ISO 5752, EN 558-1, ASME B16.10, MSS SP-68

Testing & Inspection Standards:: API 598; EN 12266-1; ISO 5208; BS 6755-1

Certifications & Conformity: ISO 9001:2015; CE Marking (PED); SIL 3; EAC; BV

Technical description

Download

Q&A

Specification of the Valve |

|

|---|---|

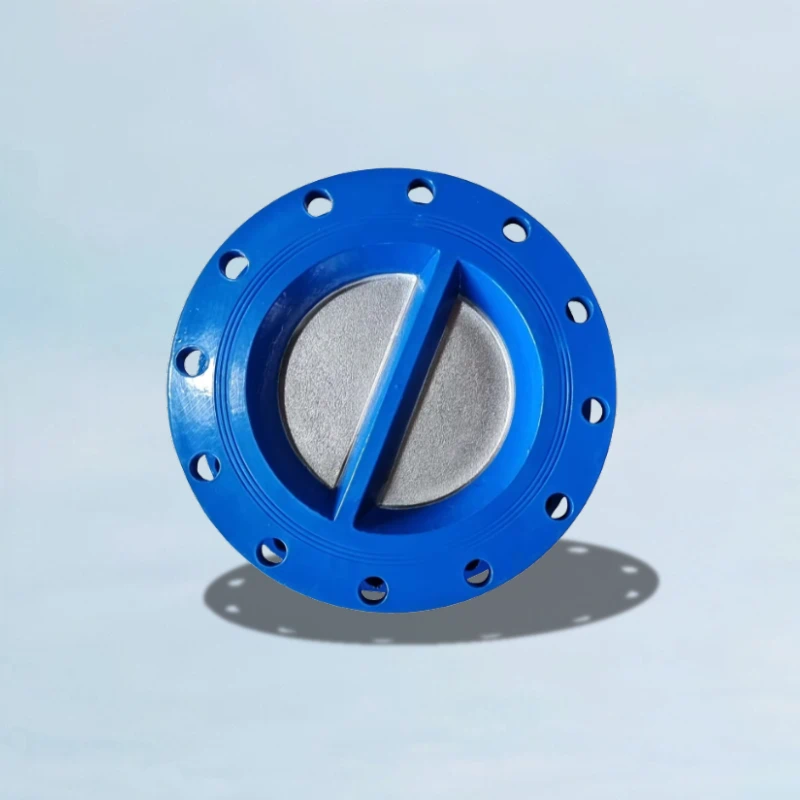

| Type of Connection | Double Flanged |

| Size |

DN32~DN1200 (1 1/4~48in) |

| Pressure |

0bar~18bar (0mpa~1.8mpa) |

| Testing Pressure |

Shell: 1.5 x Rated Pressure; Seat: 1.1 x Rated Pressure (acc. to API 598) |

| Medium | Water/Oil/Air |

| Medium Temperature | -25~180℃ |

Material of the Valve |

|

|---|---|

| Body |

Carbon Steel (WCB, WCC) Low-Temp Carbon Steel (LCB, LCC, LC1) |

| Disc |

Cast Iron: DI, CI Stainless Steel: CF8 (304), CF8M (316), CF3 (304L), CF3M (316L), CD3MN (Duplex 2205), CE3MN (Super Duplex 2507), 1.4529 (926) Aluminum Bronze: C95400, C95800 Nickel Alloy: CW6MC (Hastelloy C-276 eq.) |

| Stem |

Carbon Steel: 45# Stainless Steel: SS410, SS416, SS420; SS304, SS316, SS304L, SS316L; 17-4PH (SS630); Duplex 2205, Super Duplex 2507, 1.4529 Nickel Alloy: Monel K500, Hastelloy C-276 |

| Seat | Elastomers: EPDM, HTEPDM, NBR (Nitrile Rubber / Buna-N), SIL (VMQ), FKM (VITON™), HYPALON™ |

| Coating | Epoxy Resin 200um ~250um |

Engineered for reliability and robust performance, the Double Flanged Dual Plate Check Valve is the definitive choice for larger pipelines and demanding services. Its secure, bolted installation and efficient dual-plate design make it indispensable across various heavy-duty sectors. Below are key industries where our valves provide critical backflow prevention.

In oil and gas transport pipelines and refining processes, safety is paramount. The secure, leak-free bolted connection of the Double Flanged Dual Plate Check Valve is essential for preventing backflow at pump and compressor stations, ensuring operational integrity in high-pressure applications.

For large-scale municipal water networks and treatment plants, our Double Flanged Dual Plate Check Valve is vital. Installed at pump outlets, it protects equipment from damaging water hammer and reverse flow, ensuring a consistent and reliable water supply for communities.

In extensive HVAC systems for large buildings and district heating networks, maintaining unidirectional flow is key. The robust construction of the Double Flanged Dual Plate Check Valve provides long-term, maintenance-free backflow prevention in high-volume water circulation loops.

Thermal power plants rely on dependable equipment for continuous operation. The Double Flanged Dual Plate Check Valve is engineered for high-pressure, high-temperature services such as boiler feedwater and cooling water systems, providing the reliability needed to keep the power on.

Steel mills present a rugged industrial environment. Our heavy-duty Double Flanged Dual Plate Check Valve is built to withstand these conditions, providing steadfast backflow control in critical applications like cooling water circuits, gas pipelines, and dust suppression systems.

From factory-wide compressed air networks to steam lines, the Double Flanged Dual Plate Check Valve offers a versatile and robust solution. Its flanged body allows for easy installation and maintenance, making it a preferred choice for preventing reverse flow in a multitude of industrial processes.

While our Carbon Steel Double Flanged Dual Plate Check Valve is highly versatile, selecting the correct material is crucial for safety and longevity. It is important to understand the applications where this specific model is not suitable.

This valve is not suitable for strong acids, alkalis, or corrosive salt solutions. Carbon steel will rapidly corrode in such media. For these applications, valves made from Stainless Steel (316L), special alloys, or those with a PFA/FEP lining are required.

Seawater contains high levels of chloride, which is extremely corrosive to carbon steel. This valve should not be used in marine engineering or desalination plants. Materials like Duplex Stainless Steel, Monel, or Aluminum Bronze are necessary to resist saltwater corrosion.

These industries demand stringent hygienic standards. The potential for rust and contamination makes carbon steel unacceptable. Only valves made from food-grade stainless steel (typically 316L) with sanitary finishes should be used to ensure product purity.

Choosing the correct check valve depends on your system's pressure, size, space, and maintenance requirements. Below is a comparison to help you understand where our Double Flanged Dual Plate Check Valve excels.

The heavy-duty champion for security and reliability. This valve is bolted directly to each pipe flange, creating an exceptionally strong and stable connection.

Key Advantages: Maximum safety, ideal for high pressure and large diameters, and easy to maintain or replace without disturbing the pipeline.

Best Suited For: Critical applications, pump and compressor stations, end-of-line service, and any system where reliability is the absolute top priority.

The compact and efficient solution. This valve is held in place by being "sandwiched" between two pipe flanges using long through-bolts, making it very lightweight and space-saving.

Key Advantages: Very short face-to-face dimension, lightweight, lower cost, and fast-closing plates that minimize water hammer.

Best Suited For: HVAC, water services, and general industry where space and weight are critical constraints and pressures are moderate.

The simple and traditional choice for low-pressure systems. It features a single disc that swings open to allow flow, offering a full, unobstructed path.

Key Advantages: Simplest design, lowest pressure drop due to its full-bore opening, and often the most economical option.

Best Suited For: Low-pressure, non-pulsating flow applications where potential for valve slam (water hammer) is minimal, such as in gravity-fed lines.

Our competitive edge lies in our state-of-the-art manufacturing facility. We utilize high-precision CNC machining centers to ensure every Double Flanged Dual Plate Check Valve meets exact design specifications. This commitment to precision engineering guarantees superior quality, flawless performance, and extended service life for all our products.

Quality is the cornerstone of our brand. Our products and processes are independently audited and certified to meet the highest international standards, ensuring that you receive a valve you can trust.

Ready to configure for your project?

A Double Flanged valve provides superior security and stability. Each flange is independently bolted to the pipe, creating a robust, zero-movement connection ideal for high-pressure systems, large pipelines, and critical applications. It also allows for easier maintenance, as the valve can be removed without separating the entire pipeline.

The two lightweight, spring-loaded plates have a much shorter distance to travel than a single large disc. This allows them to close extremely quickly upon flow reversal, preventing the buildup of reverse flow momentum. This rapid action effectively minimizes the pressure surge, or 'slam,' that causes water hammer, protecting pumps and piping systems.

Yes, absolutely. The spring-assisted design ensures the plates close effectively regardless of orientation. This valve can be installed in horizontal pipelines or in vertical pipelines with upward flow. The robust flanged connection makes it stable and secure in any approved position.

Yes, it is perfectly suited for end-of-line applications. Unlike a wafer valve, which requires the compression of two flanges to be held in place, the double flanged body provides its own structural integrity. It can be securely bolted to a single upstream flange, making it an ideal choice for the end of a pipe run.

Our Double Flanged Dual Plate Check Valves are designed for bubble-tight shut-off. When equipped with a resilient seat (such as EPDM, NBR, or FKM), they provide zero-leakage performance. Every valve is rigorously tested according to API 598 standards to guarantee it meets or exceeds industry requirements for sealing integrity.