The Zero-Leakage Promise: How Bi-Directional Sealing Butterfly Valves Conquer Industry Pain Points?

In critical industrial applications, from HVAC systems to chemical processing, valve leakage is more than an inconvenience—it's a direct threat to operational efficiency, safety, and profitability. For decades, achieving a true zero-leakage, bi-directional seal was considered the domain of expensive, highly specialized valves. As a leading china butterfly valve manufacturer, we are breaking new ground by delivering this promise not just in high-end models, but across our entire range, directly addressing a core industry pain point.

Redefining Sealing Performance Beyond the Triple Offset

Our innovation lies in a fundamental structural redesign that achieves bi-directional, bubble-tight sealing in valves accessible to everyone.

Advanced structural design enables zero-leakage even in soft-seated valve models.

A New Paradigm in Sealing Technology

The industry has long relied on the complex triple eccentric butterfly valve or triple offset butterfly valve for demanding, zero-leakage applications. While effective, the high cost of a metal seated butterfly valve with a triple offset design can be prohibitive for many small and medium-sized enterprises. We recognized this challenge. Our innovation is a patent valve technology that achieves bi-directional, bubble-tight sealing in our double eccentric butterfly valve and even our soft-seated centerline valve models. This isn't a costly add-on; it’s a smarter butterfly valve design that enhances the performance of a standard wafer type butterfly valve or lug type butterfly valve without inflating the price. Understanding the difference between double offset and triple offset butterfly valves is key; we deliver the performance you need at a price that makes sense. Whether you require a high performance butterfly valve (HPBV) compliant with API 609 standards or a reliable epdm seat butterfly valve, our engineering ensures leakage is a problem of the past.

The Source Factory Advantage: Mastery Over Metal and Machining

Our promise is built on a foundation of 20 years of hands-on experience and complete in-house control over the entire manufacturing process.

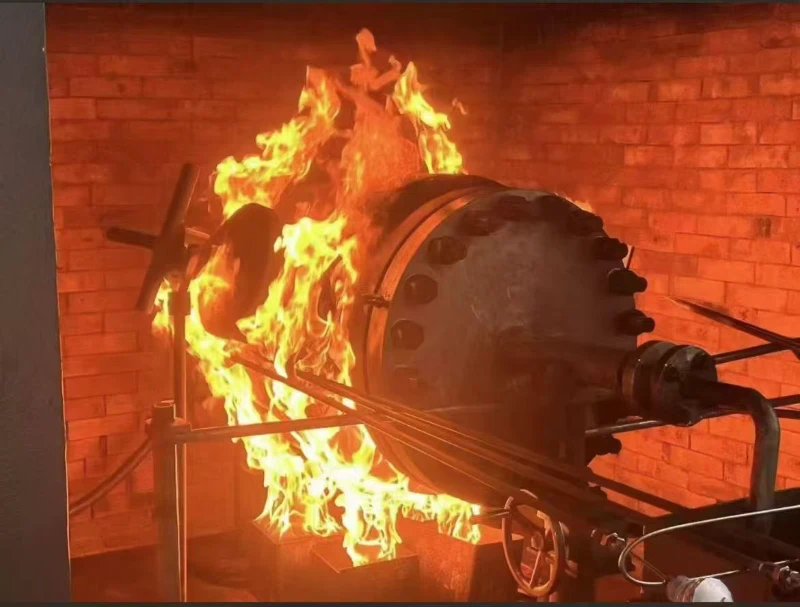

Casting Expertise and Material Integrity

Our ability to deliver on the zero-leakage promise is not accidental. It stems from our origin as a casting specialist. Founded by a casting expert, we guarantee that every butterfly valve casting meets precise international standards, whether it's a stainless steel butterfly valve (like a butterfly valve ss316 or cf8m butterfly valve), a carbon steel wcb butterfly valve, or a specialized alloy like Hastelloy. This control over raw materials for every industrial butterfly valve is the first step to a superior final product. Many butterfly valve manufacturers outsource this critical step, but we believe true quality starts at the source.

Precision Valve Machining for a Perfect Seal

A perfect seal requires perfect geometry. Our state-of-the-art cnc butterfly valve machining centers ensure that all butterfly valve components, from the body to the disc, are manufactured to exact, custom specifications ("专标专供"). This precision in butterfly valve disc machining and seat integration is crucial for the performance of every double offset butterfly valve we produce. From initial valve machining to final butterfly valve assembly, we meticulously control every variable. This ensures that every lug butterfly valve and flange butterfly valve leaving our butterfly valve factory is flawless.

A Versatile Portfolio for Diverse Industrial Needs

Our engineered solutions cater to a vast range of applications, offering comprehensive options in design, actuation, and materials.

Connection Types for Any System

We offer a complete selection including the popular wafer butterfly valve, the robust lug type butterfly valve, and the heavy-duty double flanged butterfly valve. We help clients understand the wafer vs lug type butterfly valve differences to select the best fit, from a semi lugged butterfly valve to a fully lugged model.

Wide Range of Actuation Options

Control your flow with precision. Choose from a manual butterfly valve with handle, a lever operated butterfly valve, or automated solutions like a pneumatic butterfly valve or an electric actuated butterfly valve with a worm gear actuator. Every actuated butterfly valve is calibrated for reliability.

Specialized Materials and Applications

Our expertise extends to a sanitary butterfly valve for hygienic processes, a cryogenic butterfly valve for low temperatures, a high temperature butterfly valve, and chemically resistant ptfe lined butterfly valve (or teflon lined butterfly valve) models. We also offer a high-quality range of wafer check valve solutions, including the dual plate wafer check valve.

High-Performance Valves for the Modern SME

We deliver the reliability of a major brand without the exorbitant price tag, making high performance accessible to all businesses.

As a source factory, we provide premium quality directly to our clients, bypassing costly middlemen.

We understand the challenges faced by small and medium-sized enterprises. You need the reliability of a major brand but cannot afford the associated costs. This is precisely our focus. As one of the premier manufacturers of butterfly valves in China, we offer a superior value proposition. Unlike dealing with a simple butterfly valve supplier, by choosing us you are partnering directly with a china butterfly valve factory that prioritizes quality. Whether you need a single 4 inch butterfly valve or a large order of pn16 butterfly valve units, our pricing is competitive against premium brands. We are the butterfly valve supplier china of choice for companies that refuse to compromise on quality and demand performance from their eccentric butterfly valve and other flow control solutions.

From a 2 inch butterfly valve for a small pipeline to a large diameter 24 inch butterfly valve for a major water project, our commitment remains the same. The debate of gate valve vs butterfly valve often ends with the butterfly valve winning on cost and space; we ensure it also wins on performance. Our team is ready to provide any technical data you need, from a butterfly valve diagram to a butterfly valve bolt chart for a lug type butterfly valve installation. Our goal is to be more than a supplier; we aim to be your long-term partner in flow control excellence.

Ready to Eliminate Valve Leakage?

Discover our innovative bi-directional sealing butterfly valves.

JRVAL

JRVAL Aug 25 2025

Aug 25 2025