From Design to Production: 3D Modeling Technology's Role in Shortening Butterfly Valve Customization Cycles

In today's fast-paced industrial landscape, speed and precision are paramount. At JRVAL, we've revolutionized the customization process by integrating advanced 3D modeling directly with our source factory capabilities in casting, valve machining, and butterfly valve assembly. Discover how this synergy benefits small and medium-sized enterprises seeking a high-quality, cost-effective industrial butterfly valve.

The Digital Blueprint: Precision Starts with 3D Modeling

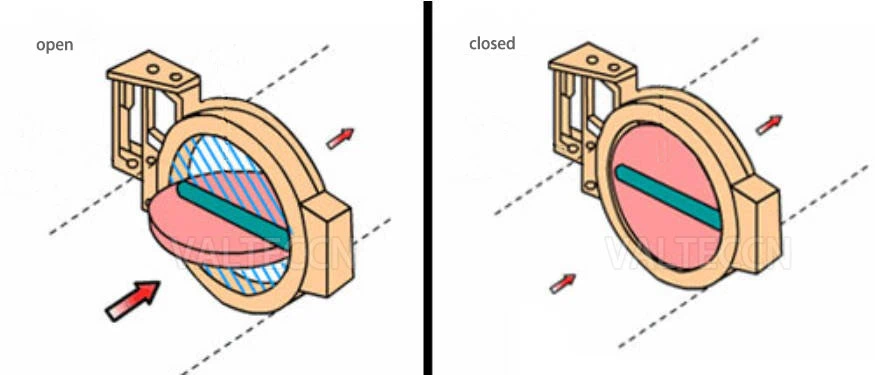

The journey of a custom industrial bv valve begins in a digital environment. Before any metal is poured, a complete 3D model allows us to simulate performance, verify fitment, and ensure every detail of the final product meets exacting client specifications.

Optimizing Core Butterfly Valve Components Digitally

Every part shown in the butterfly valve diagram is digitally perfected. This virtual prototyping is a key advantage for any type butterfly valve, from a 2 inch butterfly valve to a large diameter 24 inch butterfly valve.

- Body: 3D modeling allows us to optimize the design of any butterfly valve body, whether it's a wafer type, a fully lugged butterfly valve, a semi lugged butterfly valve, or a double flanged butterfly valve. We can ensure maximum strength and flow efficiency while minimizing material usage, a direct cost benefit. The difference between wafer type and lug type butterfly valve installation requirements can be precisely modeled.

- Disc: The disc's geometry is critical for performance. For a high performance butterfly valve (hpbv) or an offset butterfly valve, we model the precise curvature and sealing edge to guarantee tight shut-off and minimize torque. This is how we achieved our patent valve for bi-directional zero-leakage in soft-seated valves through structural changes, not added costs.

- Stem & Actuator Connection: The model verifies the integrity of the stem and the top flange, ensuring perfect compatibility with any butterfly valve actuator type, from a simple butterfly valve with handle to a complex pneumatic butterfly valve or electric actuated butterfly valve manufacturer's product.

- Seat: We can simulate the interaction between the disc and the seat ring for butterfly valves. This is crucial for selecting the right butterfly valve seat material, whether it's an epdm seat butterfly valve, a ptfe lined butterfly valve, or a metal seated butterfly valve, predicting wear patterns and guaranteeing long service life.

From Casting to Reality: Where Expertise Meets Technology

As a butterfly valve factory with roots as a foundry, JRVAL bridges the crucial gap between digital design and physical production. Our owner's 20 years of expertise as a casting specialist ensures that the flawless digital model becomes a physically superior valve body.

The 3D model's design intent is perfectly translated into the physical valve's quarter-turn functionality.

The 3D model isn't just a picture; it's the direct input for our modern butterfly valve casting process. This allows for unparalleled accuracy in creating the initial valve body. A more precise initial casting means less subsequent butterfly valve machining is required, saving time, reducing waste, and lowering costs for our customers. This is the advantage of being a source china butterfly valve manufacturer with full process control.

Our commitment to quality starts here. We guarantee that all materials conform to the required standards, whether the client specifies a stainless steel butterfly valve (like butterfly valve ss304 or ss316), a carbon steel butterfly valve (like a wcb butterfly valve), or a special alloy like Hastelloy. This rigorous material control is a core strength of our butterfly valve factory and applies to all products, including our robust wafer check valve and silent wafer check valve lines.

Precision Machining & Assembly: The Final Step to Perfection

A flawless design and a perfect casting require expert cnc butterfly valve machining to become a high-performance valve. Our specialized processes, guided by the original 3D models, guarantee the dimensional accuracy needed for superior performance across all valve types.

1. Concentric (Centerline Valve)

For the standard resilient seated butterfly valve, often called a centerline valve or soft seat butterfly valve, precision machining of the body and disc ensures concentricity. This perfect alignment extends the life of the rubber seat butterfly valve (e.g., EPDM or NBR seat) by distributing pressure evenly, preventing premature wear on this common water butterfly valve.

2. Double Offset (High Performance Butterfly Valve)

The design of a double eccentric butterfly valve relies on the precise machining of two distinct offsets. This creates a cam action, pulling the disc away from the seat upon opening. Our CNC-guided process ensures this geometry is perfect, minimizing friction and making the double offset butterfly valve ideal for higher pressures, temperatures, and frequent cycling. What is a double offset butterfly valve? It's a leap in performance enabled by machining accuracy.

3. Triple Offset (Triple Eccentric Butterfly Valve)

The triple offset valve is the pinnacle of butterfly valve design, requiring the most complex butterfly valve disc machining. The third offset creates a conical sealing profile, enabling frictionless, torque-seated, zero-leakage performance with a metal to metal seated butterfly valve. This is critical for severe service applications like high temperature butterfly valve or cryogenic butterfly valve uses. As leading triple eccentric butterfly valve manufacturers, our ability to machine these complex surfaces to micron tolerances, according to standards like API 609, is a key differentiator.

The JRVAL Advantage for Small & Medium Enterprises

Our integrated, technology-driven process isn't just about making a better valve; it's about delivering tangible benefits that make high-quality valve technology accessible, especially for SMEs who need quality without the big-brand price tag.

JRVAL's 3D-Integrated Process

- Shortened Cycle Times: 3D modeling and virtual simulation drastically reduce development time from concept to delivery. Custom solutions are faster than ever.

- Enhanced Accuracy: Digital designs feed directly into our CNC machining centers, eliminating translation errors and ensuring every valve meets precise specifications like PN16 butterfly valve standards.

- Cost-Effective Innovation: We test new designs, like our bi-directional soft-seal valve, virtually. This achieves performance breakthroughs without the cost of physical prototyping.

- Source Factory Control: As a china butterfly valve supplier with end-to-end control, we ensure quality at every step, offering a price advantage over larger brands for a superior product.

Traditional Customization Process

- Long Lead Times: Reliance on 2D drawings, manual interpretations, and multiple physical prototypes creates significant delays.

- Risk of Errors: Communication gaps between separate design firms, foundries, and machine shops often lead to costly mistakes and rework.

- Multiple Vendors: Coordinating with different suppliers for casting, machining, and assembly creates logistical headaches and inconsistent quality control.

- High Modification Costs: Changes to the design late in the process are extremely expensive and time-consuming, hindering flexibility.

Serving Diverse Industries with Tailored Solutions

Our rapid customization process allows us to effectively serve a vast range of industries, delivering the exact butterfly valve performance needed for each unique application.

Our valves are trusted in critical industrial facilities worldwide.

- HVAC & Waterworks: Our cost-effective lug type and wafer style butterfly valve options are ideal for chiller isolation and water distribution. A 6 inch butterfly valve or 8 inch butterfly valve is common in these systems.

- Chemical Processing: For corrosive media, we provide a specialized teflon lined butterfly valve or ptfe coated butterfly valve. Our high performance valve designs ensure reliable sealing.

- Food & Beverage: We manufacture a complete line of sanitary butterfly valve and sanitary check valve products, using materials like ss butterfly ss316 with polished surfaces for hygienic applications.

- Power Generation & Oil and Gas: The robust triple offset butterfly valve is specified for high pressure and high temperature steam or hydrocarbon service, where zero-leakage is critical.

- Marine & Shipbuilding: The lightweight, compact design of a lug butterfly valve makes it perfect for ballast and cooling systems where space and weight are at a premium. Our marine butterfly valve meets stringent requirements.

Explore Our Engineered Valve Solutions

Our technology-driven approach results in a superior range of butterfly valves. See how our capabilities as a premier butterfly valve supplier can meet your specific needs.

Resilient Seated Valves

The ideal, cost-effective solution for water, HVAC, and general industrial services requiring reliable, bubble-tight shutoff. Available as a lever butterfly valve or with a worm gear actuator.

View Concentric Valves

High-Performance Valves

Engineered with a double eccentric design for longer life and superior sealing in higher pressure and temperature applications, a clear step up from the standard valve butterfly wafer.

View Offset Valves

Full Butterfly Valve Catalog

Explore our complete range, including the triple eccentric butterfly valve, lined valves, and other custom-engineered solutions for any industrial challenge. We are top manufacturers of butterfly valves.

Explore CatalogHave a Custom Valve Requirement?

Our experts are ready to help you design the perfect solution.

JRVAL

JRVAL Aug 26 2025

Aug 26 2025