Lug Hole Positional Accuracy: The true position of our threaded lug hole pattern is precisely controlled to an exacting tolerance of ±0.10 mm relative to the valve centerline.

Lug Hole Positional Accuracy: The true position of our threaded lug hole pattern is precisely controlled to an exacting tolerance of ±0.10 mm relative to the valve centerline.

100% Gauge Verification: To validate this precision, every valve's lug holes are 100% inspected with certified go/no-go gauges.

100% Gauge Verification: To validate this precision, every valve's lug holes are 100% inspected with certified go/no-go gauges.

Superior Seawater Corrosion Resistance: Forms a robust, self-repairing oxide layer that provides exceptional defense against pitting and crevice corrosion in high-chloride media like seawater and brine.

Superior Seawater Corrosion Resistance: Forms a robust, self-repairing oxide layer that provides exceptional defense against pitting and crevice corrosion in high-chloride media like seawater and brine.

High Strength & Abrasion Resistance: Offers superior mechanical strength and hardness over standard brass and bronze, ensuring durability and resistance to erosion from slurries or media with solid particles.

High Strength & Abrasion Resistance: Offers superior mechanical strength and hardness over standard brass and bronze, ensuring durability and resistance to erosion from slurries or media with solid particles.

Design & Manufacturing Standards: API 609, ASME B16.34, ASME Section VIII

Leakage Class: API 598 (Bi-directional Zero Leakage)

Side Flange Standards: ASME / ANSI: Class 125LB & 150LB; EN / DIN: PN6, PN10, PN16; BS / AS: BS 10 Table D/E, AS 2129 Table D/E; JIS: 5K, 10K (JIS B2220); GB / HG/T / GOST

Top Flange (Actuator Mounting) : ISO 5211; GB 90°

Face-to-Face Dimension: API 609, ISO 5752, EN 558-1, ASME B16.10, MSS SP-68

Testing & Inspection Standards: API 598, EN 12266-1, ISO 5208, BS 6755-1

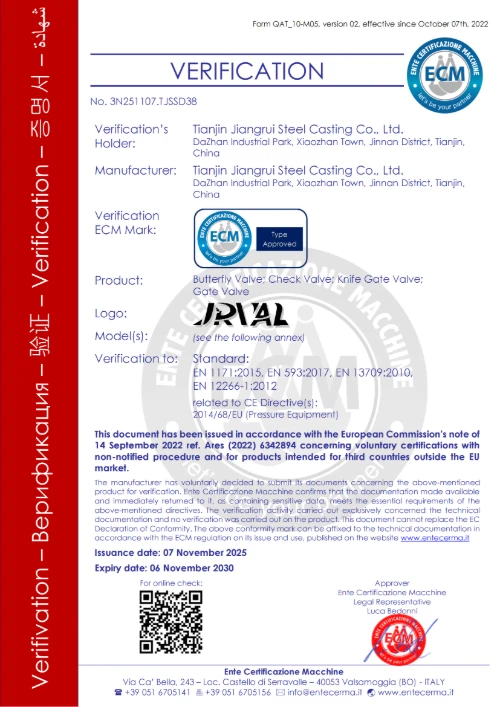

Certifications & Conformity: ISO 9001:2015; CE Marking (PED); SIL 3; EAC; BV

Technical description

Download

Q&A

Specification of the Valve |

|

|---|---|

|

Type of Connection |

Lug (NPT/Through Hole Connection) |

|

Actuation |

Bare Stem: With mounting flange per ISO 5211 |

|

Size |

NPS 2" ~ 48" (DN50 ~ DN1200) |

|

Pressure |

PN6~PN20 (Class 125~150) |

|

Testing Pressure |

Shell: 1.5 x Rated Pressure; Seat: 1.1 x Rated Pressure (acc. to API 598) |

|

Medium |

Seawater, Brackish Water, Industrial Circulating Water, Weak Acid/Alkali Media, etc. |

|

Medium Temperature |

-25℃~180℃ (Depends on seat material) |

Material of the Valve |

|

|---|---|

|

Body |

Aluminum Bronze: ASTM B148 C95400, C95800, C95500 |

|

Disc |

Aluminum Bronze: ASTM B148 C95400, C95800, C95500 Duplex Stainless Steel: CD3MN (Duplex 2205) |

|

Stem |

Stainless Steel: SS316, 17-4PH (SS630) Duplex Stainless Steel: 2205 Nickel Alloy: Monel K500 |

|

Soft Seat |

Elastomers: EPDM, HTEPDM, NBR (Nitrile Rubber / Buna-N), SIL (VMQ), FKM (VITON™), HYPALON™ Plastics: PTFE, PFA, |

Our commitment to quality is verified by internationally recognized standards. We provide the corresponding documentation to prove it.

For over 20 years, JRVAL's reputation has been built on deep material expertise and precision engineering. We control the entire process from raw material casting to final assembly, ensuring every valve meets our exacting standards.

Founded by casting experts, we guarantee material integrity from the source. Through PMI spectral testing, we verify alloy compositions, ensuring every butterfly valve casting strictly adheres to ASTM/EN standards for optimal performance and longevity.

Our advanced CNC machining centers ensure that every component's dimensions are precisely to specification. This accuracy is critical for the perfect fit and flawless operation of butterfly valve components, guaranteeing product reliability.

With two decades of field validation, our valve designs are not just theoretical but proven to be sound and reliable. This extensive experience means our products deliver consistent, dependable performance under real-world conditions.

Specifically engineered for corrosion resistance, our Aluminum Bronze Butterfly Valves are the premier choice for marine, desalination, and demanding industrial water applications where longevity and reliability are critical.

The inherent resistance of our Marine Bronze Butterfly Valve to seawater corrosion and biofouling makes it the premier choice for ballast water, cooling systems, and firefighting lines on commercial vessels, naval ships, and LNG carriers.

In reverse osmosis (RO) and multi-stage flash (MSF) plants, our Desalination Bronze Butterfly Valve provides long-term, maintenance-free service in high-salinity intake lines, brine disposal, and pre-treatment systems, outperforming lesser materials.

For FPSOs and offshore rigs, the non-sparking and seawater-resistant properties of our Offshore Bronze Butterfly Valve make it ideal for utility water, cooling circuits, and deluge fire protection systems where safety and reliability are paramount.

Power plants using seawater for cooling rely on our C95800 Butterfly Valve. Its exceptional resistance to erosion-corrosion in high-flow circulating water systems ensures plant uptime and operational efficiency.

In facilities handling brines, chlorinated water, or weak acids, this Corrosion Resistant Butterfly Valve offers a cost-effective and durable solution, preventing premature failure and contamination in industrial process water lines.

This Abrasion Resistant Butterfly Valve, with its robust aluminum bronze construction, effectively handles the transport of abrasive slurries and corrosive leaching solutions, providing superior wear life in demanding mining circuits.

Our UL/FM compliant Firefighting Bronze Butterfly Valve is trusted for deluge and sprinkler systems in marine and coastal environments. Its guaranteed performance and resistance to saltwater corrosion ensure it operates flawlessly when it matters most.

Maintaining water quality is critical in fish farming. The Aquaculture Butterfly Valve, made from bio-safe aluminum bronze, ensures no harmful elements leach into the system, providing reliable flow control for large-scale aquaculture operations.

For large-scale HVAC systems in coastal areas, our HVAC Bronze Butterfly Valve is used in condenser and chilled water loops that utilize seawater, preventing corrosion and ensuring long-term system integrity.

In the high-stakes world of ship repair, every hour a vessel spends in dry-dock is a significant cost. For a major ship repair facility in Sohar, Oman, a seemingly small component—the isolation valve—was creating a massive operational bottleneck, until a switch in valve design and supplier philosophy changed everything.

The Battle Against Downtime

Faisal Al-Harthi, the Lead Maintenance Superintendent, faced a recurring nightmare. Whenever a pump, filter, or heat exchanger in a ship's seawater cooling system needed service, his team had to drain the entire extensive pipe network. "Our old wafer-style valves were just 'sandwiched' between flanges," Faisal explained. "To remove a single pump, we had to shut down and drain meters of piping. It was a slow, messy, and wasteful process that directly impacted our project turnaround times."

Compounding the issue was the aggressive Gulf of Oman seawater. The yard had experienced premature failures with coated cast iron valves from previous suppliers who made bold claims about corrosion resistance. Faisal needed a solution that was not only operationally superior but also built from a material he could genuinely trust.

A Dual Mandate: Operational Efficiency and Absolute Material Integrity

Faisal's search was for a valve that could solve two critical problems. First, he needed a way to isolate individual pieces of equipment for service without a full system drain—a capability known as dead-end service. Second, after being let down by suppliers with questionable material quality, he required verifiable proof that the valve's alloy—in this case, Aluminum Bronze (C95400/C95800)—was authentic and properly manufactured to withstand long-term seawater immersion.

We understood that for Faisal, a valve wasn't just a flow-control device; it was a tool to enable faster, safer maintenance. We presented our Lever-Operated Aluminum Bronze Lug Butterfly Valve, focusing not just on the product, but on the engineering and manufacturing philosophy behind it.

This was the game-changer for Faisal. We explained how the lug-style body, with its individual threaded inserts, allows the valve to be bolted directly to one pipe flange while the other side is removed. This creates a secure, reliable seal for dead-end service. His maintenance team could now isolate a single pump for replacement, leaving the rest of the system charged and operational. This single feature promised to cut maintenance times on key systems by over 50%.

To address Faisal's deep-seated concerns about material quality, we leveraged our greatest strength: our identity as a foundry. We explained that our owner is a 20-year casting expert and that we control the entire process from raw ingot to finished valve in our 81,426 m² facility. We provided him with our internal QC documentation, including PMI (Positive Material Identification) reports for the specific heat of C95400 bronze used, proving its chemical composition. This transparency gave him the confidence that he was receiving a genuine, corrosion-resistant marine-grade alloy, not just a "bronze-colored" substitute.

A great casting is only half the story. We demonstrated how our 11 key CNC machines ensure every lug hole is tapped with perfect alignment and the valve's sealing face is machined to a precise finish. This guarantees not only easy installation but also the performance of our innovative bi-directional soft seal, which delivers bubble-tight, zero-leakage isolation—critical for reliable dead-end service. Our dimensional QC reports, measured with standard calibrated tools, provided the final layer of assurance.

We understood that a ship repair yard values reliability above all. We supported our product with a 2-year warranty covering free spare parts and highlighted that our standard design ensures easy parts sourcing in the future. Furthermore, we committed to providing remote online technical support for any installation or operational questions. This demonstrated that we were invested in his long-term success, not just a short-term sale.

For a business like Faisal's, where operational efficiency is directly tied to profitability, the right component can have an outsized impact. By combining the intelligent engineering of a lug-style body with the unimpeachable quality of a foundry-direct manufacturing process, we delivered more than a valve.

We provided a solution that solved a critical operational pain point, backed by the verifiable material integrity required for the demanding marine environment. This is our core philosophy: to act as a true engineering partner, delivering robust, reliable solutions that make our clients more efficient, competitive, and successful.

Ready to configure for your project?

The key advantage is "dead-end service." Our lug valve's threaded inserts allow it to be bolted to a single flange, isolating equipment downstream for maintenance without draining the entire system. This drastically cuts downtime and costs, especially in marine and industrial repair.

As a foundry-direct manufacturer with 20 years of casting expertise, we control quality from molten metal to finished valve. We provide Positive Material Identification (PMI) reports with every batch to verify the alloy's chemical composition, ensuring authentic, marine-grade corrosion resistance.

Every single valve undergoes rigorous pressure testing according to API 598 standards before shipment. Our combination of a precision-machined seat and an innovative bi-directional soft seal design ensures bubble-tight shutoff. We provide factory test reports to document this performance.

Yes, Aluminum Bronze is an excellent choice for hydrocarbon fluids requiring non-sparking properties. Its material composition inherently prevents the risk of friction-generated sparks, making it a safe and reliable option for oil & gas, refining, and chemical processing lines.

We offer a comprehensive 2-year warranty with free spare part replacements. Because our valves are built to universal standards, you can easily source compatible parts like seats or O-rings from us or third-party suppliers after the warranty, ensuring a low Total Cost of Ownership.