Superior Material Composition: Our valves are cast with chemical compositions at the highest end of international standards. For example, our ASTM A351 CF8 stainless steel contains 9% Nickel—the maximum allowable—to ensure superior corrosion resistance and extended service life.

Superior Material Composition: Our valves are cast with chemical compositions at the highest end of international standards. For example, our ASTM A351 CF8 stainless steel contains 9% Nickel—the maximum allowable—to ensure superior corrosion resistance and extended service life.

Lug Hole Positional Accuracy: The true position of our threaded lug hole pattern is precisely controlled to an exacting tolerance of ±0.10 mm relative to the valve centerline.

Lug Hole Positional Accuracy: The true position of our threaded lug hole pattern is precisely controlled to an exacting tolerance of ±0.10 mm relative to the valve centerline.

100% Gauge Verification: To validate this precision, every valve's lug holes are 100% inspected with certified go/no-go gauges.

100% Gauge Verification: To validate this precision, every valve's lug holes are 100% inspected with certified go/no-go gauges.

Surface Integrity: Our castings are guaranteed to be free from surface porosity, shrinkage, or unauthorized weld repairs, ensuring maximum material strength and pressure-holding capability.

Surface Integrity: Our castings are guaranteed to be free from surface porosity, shrinkage, or unauthorized weld repairs, ensuring maximum material strength and pressure-holding capability.

Design & Manufacturing Standards: API 609, ASME B16.34, ASME Section VIII

Leakage Class: API 598 (Bi-directional Zero Leakage)

Side Flange Standards: ASME / ANSI: Class 125LB & 150LB; EN / DIN: PN6, PN10, PN16; BS / AS: BS 10 Table D/E, AS 2129 Table D/E; JIS: 5K, 10K (JIS B2220); GB / HG/T / GOST

Top Flange (Actuator Mounting) : ISO 5211; GB 90°

Face-to-Face Dimension: API 609, ISO 5752, EN 558-1, ASME B16.10, MSS SP-68

Testing & Inspection Standards: API 598; EN 12266-1; ISO 5208; BS 6755-1

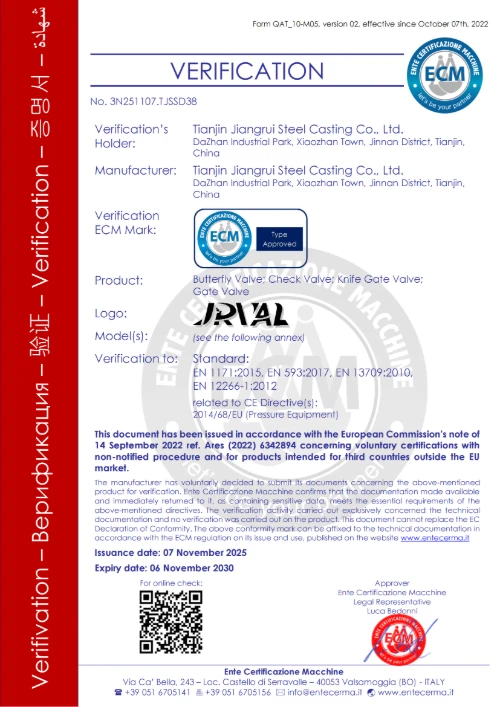

Certifications & Conformity: ISO 9001:2015; CE Marking (PED); SIL 3; EAC; BV

Technical description

Download

Q&A

Specification of the Valve |

|

|---|---|

|

Type of Connection |

Lug (NPT/Through Hole Connection) |

|

Actuation |

Pneumatic Actuator |

|

Size |

NPS 1 ½" ~ 48" (DN40 ~ DN1200) |

|

Pressure |

6bar~20bar (Class125/150) |

| Testing Pressure | 1.5 x Rated Pressure |

|

Medium |

Water, Oil, Gas, Steam, Corrosive Media, Slurry, etc. |

|

Medium Temperature |

-25℃~180℃ (Depends on seat material) |

Material of the Valve |

|

|---|---|

|

Body |

Stainless Steel: CF8 (304), CF8M (316), CF3 (304L), CF3M (316L), JS1030, 1.4406 Duplex Stainless Steel: 2205, 2507 Austenitic Stainless Steel: 1.4529, CN7M (Alloy 20) |

|

Disc |

Cast Iron: DI, CI Stainless Steel: CF8 (304), CF8M (316), CF3 (304L), CF3M (316L), CD3MN (Duplex 2205), CE3MN (Super Duplex 2507), 1.4529 (926) Aluminum Bronze: C95400, C95800 Nickel Alloy: CW6MC (Hastelloy C-276 eq.) |

|

Stem |

Carbon Steel: 45# Stainless Steel: SS410, SS416, SS420; SS304, SS316, SS304L, SS316L; 17-4PH (SS630); Duplex 2205, Super Duplex 2507, 1.4529 Nickel Alloy: Monel K500, Hastelloy C-276 |

|

Seat |

Elastomers: EPDM, HTEPDM, NBR (Nitrile Rubber / Buna-N), SIL (VMQ), FKM (VITON™), HYPALON™ Plastics: PTFE, PFA |

|

Pneumatic Actuator |

Anodized Aluminum Alloy, Stainless Steel |

Double Acting: Utilizes air pressure to both open and close the valve.

Single Acting / Spring-Return: Utilizes air pressure for one action and spring force for the fail-safe return.

- Normally Closed (NC) / Fail-Close: The spring closes the valve upon loss of air pressure.

- Normally Open (NO) / Fail-Open: The spring opens the valve upon loss of air pressure.

On/Off: For fully open or fully closed service, providing simple and reliable isolation.

Modulating: For precise flow control by positioning the disc at any angle. Requires an electro-pneumatic positioner.

Electro-magnetically Released: A specialized double-acting actuator configuration designed for specific safety or emergency shutdown applications.

Additional Options: Other custom configurations are available upon request to meet your unique requirements.

Our butterfly valve stainless bodies are produced from a high-density casting process. This ensures a solid, non-porous structure, completely free from sand holes and other casting defects. The result is superior strength and maximum durability.

Learn More About Our ProcessOur commitment to quality is verified by international standards, ensuring our products are trusted worldwide.

The fast-acting, reliable nature of pneumatic actuation makes this valve essential for automated systems. It enables rapid on/off service, precise process control, and integration into safety-critical shutdown (ESD) systems.

In batch processing, the rapid and repeatable action of a pneumatic butterfly valve ensures precise dosing of reagents. Its fail-safe capability is vital for isolating reactors during emergency shutdowns.

Ideal for automated filter backwash cycles where frequent, fast operation is required. The actuated butterfly valve integrates seamlessly with PLC systems for unattended, reliable plant operation.

Used in non-critical utility lines, tank farm isolation, and automated fluid transfer. The robust design of the butterfly valve oil and gas industry models ensures reliability in demanding field conditions.

The stainless steel pneumatic butterfly valve integrates with Building Management Systems (BMS) for automated control of heating and cooling loops, optimizing energy consumption in large facilities.

Automates control of process water, chemical additives, and white liquor lines. A high-cycle cf8m butterfly valve provides the durability needed for the continuous operation common in paper production.

Controls flow in abrasive slurry lines and dust suppression systems. The secure end-of-line installation of a lugged and tapped butterfly valve with a powerful actuator ensures reliable shut-off.

Essential for automated Ballast Water Management Systems (BWMS). The corrosion resistance of ss 316 butterfly valves is critical for longevity in seawater and brackish water applications.

Used for rapid isolation of cooling water circuits and in flue-gas desulfurization (FGD) systems where quick response times are crucial. As trusted china pneumatic butterfly valve suppliers, we guarantee performance.

Our valves are a core component for OEM machine builders. Understanding the butterfly valve with pneumatic actuator working principle allows for seamless integration into compact, automated process skids.

Our pneumatic lug butterfly valves are engineered to perform reliably under a wide range of operational challenges and site conditions.

For over 20 years, our reputation has been built on a foundation of deep material expertise and precision engineering. We control the entire process, from raw casting to final assembly, ensuring every valve meets our uncompromising standards.

Founded by a casting expert, we guarantee material integrity. We use PMI testing to verify alloys, ensuring every valve casting strictly adheres to ASTM/EN standards for optimal performance and longevity.

Our state-of-the-art CNC centers ensure every component's dimensions are machined to exact specifications. This precision is critical for the perfect fit and flawless operation of the valve assembly.

With two decades of field validation, our valve designs are not just theoretical; they are proven to be rational and reliable, delivering consistent, trustworthy performance in real-world conditions.

The right combination of body alloy, disc material, and seat polymer is critical for ensuring long service life in corrosive environments.

For AutoChem Solutions, a producer of high-value specialty chemicals, process control is paramount. An uncontrolled reaction or slow response time doesn't just spoil a batch—it's a critical safety incident. Their challenge was to upgrade their reactor feed lines from slow, unreliable manual valves to a fully automated, fail-safe system.

More Than a Valve... A Guardian of Process Safety

"Our process involves feeding precise amounts of catalyst into a reactor. The timing is everything," explains David Chen, Chief Process Engineer at AutoChem. "With manual valves, we faced inconsistent closing times and, frankly, human error. An emergency shutdown required an operator to physically run to three separate valves. This was an unacceptable risk in our HAZOP analysis. Previous automated valves from another supplier failed after just a few months due to high cycle counts."

AutoChem needed a valve assembly that wasn't just automated, but engineered for high-cycle industrial reality, offering instant, reliable shutdown under any condition.

When Automation Fails: The Peril of Under-Engineered Components

AutoChem's core problem was a lack of reliable automation. Their application required over 50 open/close cycles per day. The previous supplier's valves suffered from actuator fatigue, stem twisting, and seat leakage. "The system had to be dependable. We needed a 'fire-and-forget' solution that our PLC could trust implicitly," Chen emphasizes. "A valve that sticks open during a shutdown sequence is our worst-case scenario. We needed a partner who understood dynamics, fatigue life, and fail-safe engineering, not just catalog parts."

This was a classic challenge where a standard off-the-shelf assembly would fail. Our solution was a fully engineered system, specified from the ground up: Our High-Endurance CF8M Stainless Steel Lug Butterfly Valve with a Spring-Return Pneumatic Actuator.

We didn't just pick an actuator; we engineered the choice. Analyzing their 6 bar air supply and 80°C media, we calculated the dynamic fluid torque and stem friction. We then applied a 1.5x safety factor to specify a rack-and-pinion spring-return, fail-close pneumatic actuator. Why is this vital? On any loss of plant air or control signal, the pre-loaded springs provide the stored mechanical energy to instantly and forcefully close the valve, isolating the reactor without external power. This is the cornerstone of a safe automated system.

To withstand 50+ daily cycles, we focused on failure points. The valve stem is not standard SS316; it's machined from 17-4PH stainless steel, then precipitation-hardened to HRC 44. This provides superior torsional strength to prevent twisting over thousands of cycles. We incorporated dual reinforced PTFE (RPTFE) stem bushings, which provide low-friction support and prevent the galling that plagued their previous valves. Crucially, the CF8M disc edge is CNC-machined to a spherical profile and polished to a mirror finish (Ra < 0.2 µm), drastically reducing friction and wear on the seat, guaranteeing a bubble-tight seal for over 100,000 cycles.

The valve body is cast from CF8M (316 SS), subjected to a 1060°C solution annealing heat treatment and rapid water quench. This metallurgical process eliminates chromium carbides, preventing the intergranular corrosion that could compromise the valve's structural integrity. For the catalyst feedstock, we specified a TFM 1600 seat, a modified PTFE that offers superior chemical resistance and lower torque requirements than standard PTFE, reducing the load on the actuator and extending its life.

We delivered a pre-assembled and tested package. This included an ATEX-rated explosion-proof 5/2 way NAMUR solenoid valve for safe electrical actuation and a limit switch box with a high-visibility beacon indicator. This provides both visual confirmation on the plant floor and clear open/closed feedback to AutoChem's central PLC system. Every single assembly was pressure tested and subjected to a 100-cycle functional test before shipment.

Automated, Fail-Safe Control for Your Process

The primary reason is inherent, long-term corrosion resistance. A stainless steel valve's resistance is integral to the metal itself. Coatings on carbon steel can be scratched, chipped, or degrade over time, exposing the base metal and leading to catastrophic failure. For critical applications in chemical, marine, or processing industries, a solid stainless steel body provides unmatched reliability and eliminates the risk of process contamination from a failed coating.

CF8 (304 SS) and CF8M (316 SS) are the standard cast grades for austenitic stainless steel. The critical manufacturing step is Solution Annealing. We heat the raw casting to over 1060°C and then rapidly quench it in water. This process dissolves harmful chromium carbides at the grain boundaries, which prevents intergranular corrosion and ensures the material's maximum, uniform corrosion resistance throughout the valve body.

The key benefit is its suitability for dead-end service. Each threaded lug hole allows the valve to be bolted to one flange while the other side of the pipeline is removed for maintenance. This isolates a section of the system without needing to drain the entire line. This feature is invaluable in chemical plants, water treatment facilities, and complex piping networks where system uptime is critical.

The choice depends on the corrosiveness of your media. 316 (CF8M) contains Molybdenum, which significantly enhances its resistance to chlorides (like saltwater) and a wider range of industrial chemicals. Choose 304 (CF8) for general corrosion resistance in applications like water, food, and mild chemicals. Choose 316 (CF8M) for more aggressive environments such as marine applications, chemical processing, pharmaceuticals, and pulp & paper to prevent pitting and crevice corrosion.

It is delivered as a fully assembled and factory-tested unit. We professionally mount the correct-sized pneumatic actuator to the valve's ISO 5211 standard top flange and perform multiple cycle tests. This 'plug-and-play' approach guarantees perfect alignment and reliable performance, saving you significant time and potential errors during on-site installation.

As a source factory integrating casting, machining, and assembly, JRVAL's product reliability has been verified by the market for over 20 years.

Compare our products against other brands before you commit. We're confident you'll be satisfied after an in-depth investigation.

We provide a comprehensive 2-year warranty covering non-human damage. Spare parts for the valve body, disc, seat, and gear operator are readily available.

Before delivery, we provide complete documentation, including material test reports, heat treatment reports, and mechanical performance tests.