CLEVELAND, OH – For small to medium-sized enterprises (SMEs) like Apex Manufacturing, a mid-sized producer of specialized liquid additives, operational efficiency isn't just a goal; it's a lifeline. For years, their plant manager, David Miller, battled a recurring, frustrating problem: unplanned shutdowns caused by failing butterfly valves in their fluid control lines. The issues ranged from simple leaks to complete failures of their basic wafer butterfly valve and lug type butterfly valve units.

"It felt like a game of whack-a-mole. We'd replace a leaking butterfly valve here, and another would start dripping across the plant. Each stop meant hours of lost production, wasted materials, and overtime for the maintenance crew. We were saving a few hundred dollars on the initial valve purchase, but losing thousands in downtime. The true cost of a cheap valve butterfly valve was staggering."

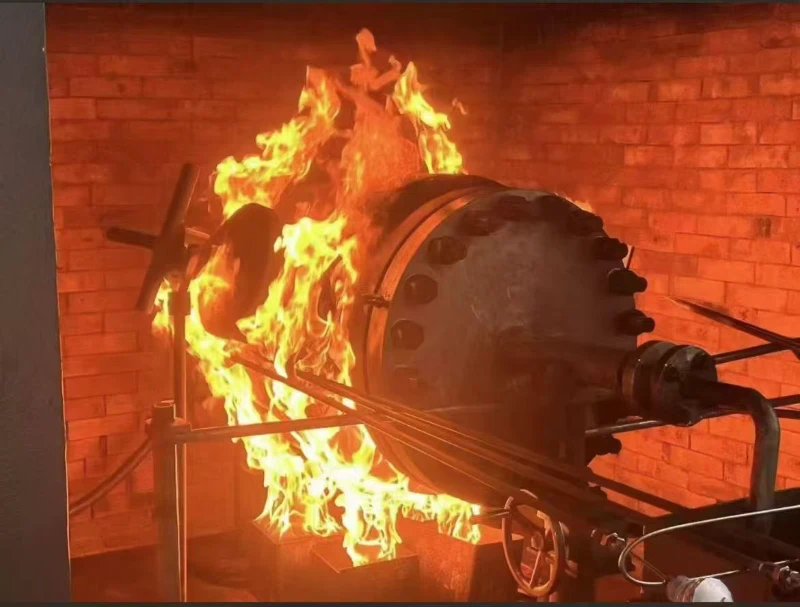

API 607 Fire Test in Progress: Validating valve integrity under extreme conditions.

This test ensures our butterfly valve meets low-leakage requirements after fire exposure, guaranteeing system safety.

The "Cheap Valve" Trap

This is a familiar story for many SMEs. In an effort to control upfront costs, procurement often defaults to the lowest bidder for standard components. However, the experience at Apex Manufacturing serves as a powerful case study on the Total Cost of Ownership (TCO) and the profound impact that component quality, from a simple water butterfly valve to a more complex triple eccentric butterfly valve, has on the bottom line.

Apex's initial strategy was straightforward: source standard-spec valves from various distributors offering the most competitive prices. The problem, as they discovered, was a complete lack of consistency and quality control in these generic butterfly flange valve and wafer style models. They were using everything from a basic 4 inch butterfly valve to a 6 butterfly valve, all from different, untraceable sources.

"One batch would be fine, the next would have an epdm seat butterfly valve liner that failed prematurely. There was no traceability. We had no idea where the butterfly valve casting was made, the precision of the valve machining, or what quality control was in place. These 'bargain' valves, including some so-called stainless steel butterfly valve units that showed early signs of corrosion, were creating unacceptable risks of cross-contamination between our product lines, which could have been catastrophic for our clients."

The financial drain was significant. Miller's team calculated that over a six-month period, they had experienced over 15 separate downtime incidents directly attributable to valve failure. This included issues with a standard butterfly valve lever operated model and a gear type butterfly valve. The total cost to the company was an estimated \$75,000 in lost production and maintenance expenses. The "cheap" valves were proving to be one of their most expensive operational costs.

A Shift in Strategy: From Supplier to Partner

The turning point came during a scheduled plant-wide review. Instead of asking "Where can we find cheaper valves?", the engineering team, tired of comparing a gate valve vs butterfly valve on price alone, changed the question to "How can we guarantee valve reliability?"

This new approach led them away from faceless distributors and towards source manufacturers of butterfly valves. Their research focused on finding a china butterfly valve manufacturer that controlled the entire production process, from raw material casting to final butterfly valve assembly and testing. This is how they discovered JRVAL, a butterfly valve factory that owns and manages its entire production chain for a vast range of products, including the popular lug and wafer type butterfly valve, double flanged butterfly valve, and specialized high performance butterfly valve (HPBV) models.

"What intrigued us about a model like JRVAL's wasn't a flashy brochure, but their process transparency. They could show us the butterfly valve components, the material composition of a cf8m butterfly valve body, the precision tolerances of their cnc butterfly valve machining, and the pressure testing data for every single ss butterfly valve. It was a completely different conversation. We weren't just buying a product; we were investing in a predictable, reliable centerline valve."

Measurable Results and a New Philosophy

Apex Manufacturing decided to conduct a phased replacement of 50 critical valves with JRVAL's products, specifying models like the pn16 butterfly valve with a durable ptfe seat butterfly valve for more aggressive media. The results were immediate and dramatic.

In the twelve months following the upgrade, the company reported the following:

- A 95% reduction in valve-related downtime: From over 15 incidents to just one, which was traced to an improper lug type butterfly valve installation procedure, not component failure.

- Drastically reduced maintenance costs: The maintenance team was freed from constant emergency repairs on their 2 inch butterfly valve and 3 inch butterfly valves, allowing them to focus on preventative plant maintenance.

- Improved product safety: The consistent sealing of the new industrial butterfly valve units, including both a double offset butterfly valve and even a triple offset butterfly valve in one critical line, eliminated the risk of cross-contamination, protecting both product quality and client relationships.

"The return on investment was surprisingly fast. The slightly higher upfront cost per high performance valve was paid back in less than six months just from the savings in downtime. More importantly, it changed our procurement philosophy. We now understand that true cost-effectiveness comes from reliability and longevity from a trusted butterfly valve supplier, not just the price on the invoice. Whether we need a manual butterfly valve or a pneumatic butterfly valve, we now go directly to a quality source."

Apex's story is a microcosm of a larger trend among savvy SMEs who are realizing that in a competitive industrial landscape, quality and reliability are not expenses, but investments in their own productivity and profitability. The hidden costs of "cheap" are often far greater than the visible savings. Choosing a reputable manufacturer like JRVAL, a leading china butterfly valve supplier, ensures that every component, from a simple wafer check valve to a complex cryogenic butterfly valve, is an asset, not a liability.

JRVAL

JRVAL Sep 03 2025

Sep 03 2025