The Precision Revolution: How JRVAL’s Threaded Lug Butterfly Valve Simplifies Installation Processes

In complex industrial piping systems, the efficiency of butterfly valve installation directly impacts project timelines and costs. As a source factory with deep expertise in fluid control, JRVAL leverages its full-stream control over casting, valve machining, and assembly to launch a new generation of lug type butterfly valve designs. By innovating with high-precision threaded holes, this valve butterfly valve redefines installation standards. How does this breakthrough achieve a faster, more accurate, and more stable installation? Let's dive in.

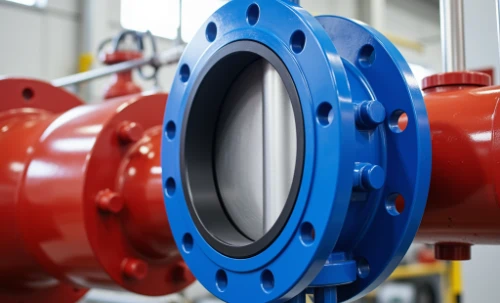

The JRVAL fully lugged butterfly valve with integrated high-precision threaded holes.

Breaking Through Bottlenecks: Three Challenges of Traditional Installation

Conventional lug and wafer style butterfly valves require a connection using through-bolts and nuts, a method that frequently presents the following challenges for technicians.

- High Dependency on Alignment: Connecting a valve between two pipe flanges is a delicate task. Any slight misalignment between the flange bolt holes and the butterfly flange valve can create stress points, leading to gasket failure and significant leakage risks. This is a critical factor in the lugged vs wafer butterfly valve debate.

- Time-Consuming and Labor-Intensive: Securing a traditional industrial butterfly valve involves handling multiple long bolts and nuts, requiring meticulous, repeated cross-pattern tightening and calibration to ensure even pressure. This process is inherently inefficient and drives up labor hours. A detailed butterfly valve bolt chart is often needed to manage the complexity.

- Complex Maintenance Procedures: During system maintenance or repair, the disassembly and reassembly of a standard butterfly valve flange connection requires loosening and retightening every single bolt, significantly extending equipment downtime and disrupting operations. While the lug type design offers dead-end service, the re-installation process remains cumbersome.

The Threaded Hole Innovation: JRVAL's "Less Is More" Philosophy

Guided by real-world user scenarios, JRVAL's technical team optimized the structure of the lug butterfly valve, focusing on a simple yet profound enhancement.

JRVAL's Solution: Precision-Engineered Threaded Holes

This design is a core feature of the butterfly lug type valve, which is also known as a fully lugged butterfly valve. Here's how it transforms the installation:

- Integrated Threaded Lug Design: The valve body's lugs are equipped with high-precision tapped (threaded) holes. This allows the valve to be directly secured to a pipe flange using cap screws, completely eliminating the need for nuts and long through-bolts. This streamlined approach makes the lug type butterfly valve installation faster and less prone to error than that of a typical wafer style butterfly valve.

- Three-Stage CNC Calibration Process: We employ state-of-the-art CNC machining centers and online inspection systems for every ss butterfly valve. This ensures a coaxiality error of the threaded holes within ≤0.05mm and a sealing face flatness of Ra0.8μm, guaranteeing a perfect, leak-free fit every time. This precision in valve machining sets a new standard for a centerline valve.

- Enhanced Standardization and Compatibility: The design supports multiple thread standards, including UN and ISO, ensuring compatibility with over 90% of industrial piping scenarios. This makes the JRVAL lug valve a versatile solution, whether it's a high performance butterfly valve or a standard water butterfly valve application, adhering to standards like API 609 butterfly valve.

Field-Tested Results: In a comparative test on a petrochemical project, the JRVAL threaded lug butterfly valve demonstrated a 62% reduction in installation time and a 45% decrease in labor costs. Furthermore, the first-time installation success rate reached an impressive 99.3%.

The Power Behind Precision: End-to-End Quality Control

As a butterfly valve factory covering the entire industry chain from casting to final assembly, JRVAL embeds precision management into every step.

- Material Traceability and Integrity: We utilize stainless steel investment casting for our stainless steel butterfly valve series (including butterfly valve ss304 and ss316). This process ensures a tensile strength of ≥450MPa and eliminates defects like porosity, which is crucial for a reliable ss butterfly. The butterfly valve casting is the foundation of our quality.

- Intelligent Machining: The threaded holes on the lug butterfly valve body are milled and formed by a five-axis linkage machining center. This advanced butterfly valve machining, combined with laser positioning technology, achieves micron-level precision, a hallmark of every CNC butterfly valve we produce.

- Dual-Layer Quality Assurance: Before leaving the butterfly valve factory, every single valve, from a small 2 inch butterfly valve to a large 24 inch butterfly valve, undergoes rigorous testing. This includes dimensional verification with a Coordinate Measuring Machine (CMM) and a high-pressure pneumatic seal test to ensure 100% compliance and zero leakage. This applies to all our products, including the double offset butterfly valve and triple eccentric butterfly valve.

Customer Voice: From "Installation Anxiety" to "Operational Freedom"

"Previously, installing a single DN300 (12 inch butterfly valve) took a team of three people about 40 minutes. With JRVAL's threaded lug style butterfly valves, one technician can complete the job in just 15 minutes. This design has not only lowered the skill threshold for our workers but has more than doubled our emergency repair efficiency."

— Project Manager, a Leading Municipal Water Group

Industry Takeaway: Precision is the New Competitive Edge

JRVAL's innovation affirms a key trend in modern industrial manufacturing: improvements in detail-level precision can trigger exponential growth in overall efficiency. Through the "micro-innovation" of a threaded hole on the lug flange, the company not only solves a major installation pain point but also champions the industry's evolution towards greater standardization, lightweight design, and enhanced reliability for every type butterfly valve.

About JRVAL

As a premier china butterfly valve manufacturer, JRVAL has focused on the R&D and manufacturing of high-performance butterfly valves for 20 years, serving over 3,000 projects in the energy, chemical, and municipal sectors worldwide. Relying on a fully independent production system, we are a trusted butterfly valve supplier that continuously empowers fluid control with technical innovation, providing customers with more durable and worry-free valve solutions, including our leading teflon lined butterfly valve and ptfe lined butterfly valve series.

Lug Type Butterfly Valve

Our flagship lug butterfly valve features precision-threaded holes for rapid, secure, and reliable dead-end service installations.

Explore Lug Valves

High-Performance Valves

Discover our range of double eccentric and triple offset butterfly valve models, engineered for critical high-pressure and high-temperature services.

View Offset Valves

Full Butterfly Valve Catalog

From a wafer type butterfly valve to a pneumatic butterfly valve, explore our comprehensive catalog to find the perfect solution for your needs.

Explore Catalog

JRVAL

JRVAL Aug 30 2025

Aug 30 2025