Handling US, German, and Japanese Standards in One Order? How JRVAL's Butterfly Valve Factory Helps SMEs Save Costs and Win Global Markets

When a Thai water treatment solutions provider received concurrent valve orders from clients in the United States and Japan, they initially prepared to source from two different factories. That was until they discovered JRVAL, a China butterfly valve manufacturer capable of producing valves compliant with both American API 609 and Japanese JIS standards within a single shipment. This "multi-standard co-production" capability is empowering a growing number of small and medium-sized enterprises (SMEs) to penetrate the international market at a significantly lower cost, turning complex requirements for products like the popular `4 inch butterfly valve` or a `stainless steel butterfly valve` into a streamlined process.

Cracking the Code: Why Small, Multi-Standard Orders Are Profitable

"Many manufacturers believe that producing small batches with multiple standards is a guaranteed loss. The real solution lies in mastering control at the source," explains the Production Director at JRVAL, pointing to a row of raw valve body castings. The `butterfly valve factory` has re-engineered its process from the foundry stage, designing base models for their `valve butterfly valve` products that are compatible with multiple international standards. For example, a single batch of `stainless steel butterfly` body castings (`ss butterfly valve`) can, through subsequent precision `valve machining`, meet the material toughness required by German DIN standards and the pressure ratings of American ASME standards. This "one-material-fits-all" approach to the `wcb butterfly valve` has slashed material waste for mixed-standard orders from an industry average of 12% down to just 3.8%.

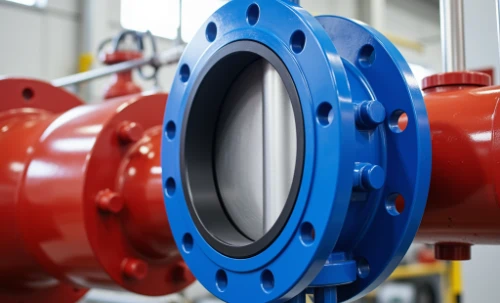

Operators seamlessly switch between standards using a modular assembly system.

Assembling Valves Like LEGOs: Switching Standards on the Fly

In the assembly workshop, the flexibility is palpable. One operator fits a `lug type butterfly valve` with a 6-hole AWWA `butterfly flange`, while the adjacent station assembles a `JIS 10K butterfly valve` with an 8-hole configuration on the same body type. "Our valve bodies are designed with universal connection interfaces," a technician demonstrates, holding up a `wafer type butterfly valve`. "It’s like a universal phone case that fits different models; we just swap out the corresponding `butterfly valve components`—flanges, sealing, an `EPDM seat butterfly valve`, or a `PTFE lined butterfly valve` seat." This modular approach extends to operation methods, easily accommodating a `butterfly valve lever operated` handle or a `butterfly valve with worm gear`. The `china butterfly valve supplier` has built a library of 217 standard component modules, enabling them to match new certification requirements for a `high performance butterfly valve` (HPBV) in as little as 72 hours.

The Savings Secret: Adjusting Parameters, Not Molds

"Traditional factories have to swap out entire mold sets to switch between standards, which is costly and time-consuming. We solve this with intelligent CNC machines," says the workshop supervisor. He initiates a program on a CNC machine, and the screen displays the valve seat being machined, simultaneously showing parameters for both German `DIN EN 593` and Chinese `GB/T12238`. "By simply adjusting the programming for machining depth and bore diameter, a single toolset can produce parts for a `double eccentric butterfly valve` or a `triple eccentric butterfly valve` meeting various standards. Last year, this saved an Indonesian client over \$32,000 in tooling fees for a custom `flange butterfly valve` order." This precision is key whether it's a `concentric butterfly valve` or a more complex `triple offset butterfly valve`.

Unyielding Quality: Dedicated Testing Lines for Each Standard

In the quality control area, three parallel testing lines are a testament to JRVAL’s commitment. The American standards section features an actuator performing 200,000 open-close cycle tests on a `pneumatic butterfly valve`. The Japanese standards line is conducting salt spray corrosion tests, crucial for `marine butterfly valve` applications. Meanwhile, the German line uses a dedicated vacuum chamber for negative pressure seal testing on a `PN16 butterfly valve`. "Though the production is integrated, the final inspection is bespoke for each client," a quality inspector notes, showing a report for a recently completed mixed order. A Middle Eastern customer’s order of 200 `industrial butterfly valve` units, spanning three different standards, achieved a 100% first-pass acceptance rate.

Real-World Success: Small Factories Winning Transnational Orders

- A Vietnamese food machinery manufacturer secured a contract with a major retailer's supply chain by sourcing `sanitary butterfly valve` units from JRVAL that simultaneously held both NSF (American) and CE (European) certifications.

- A German environmental firm saved 37% on local modification costs by ordering `DIN valve` bodies with custom interfaces, allowing direct integration into their existing systems. This demonstrated the advantage over the typical `gate valve vs butterfly valve` debate where customization is key.

- A Malaysian distributor doubled its customer order fulfillment speed by leveraging JRVAL’s mixed-standard production service for `wafer check valve` and `lug butterfly valve` products, drastically reducing lead times.

"Previously, handling multi-country orders meant juggling different suppliers, complicating logistics and increasing our inventory pressure. Now, JRVAL handles everything in one shipment. Our stock is leaner, and our profit margins are actually higher."

Conclusion: Empowering Global Ambitions

On JRVAL’s factory floor, a large digital Kanban board displays the real-time production status for orders across 23 global standards. This `china butterfly valve factory` has proven that with a powerful combination of smart source control and modular manufacturing, the international ambitions of SMEs no longer need to be hindered by the complexities of differing standards. For companies looking for a reliable `butterfly valve supplier`, this agile manufacturing model is not just saving money—it's building a bridge to the global market, one versatile `valve butterfly wafer` at a time.

JRVAL

JRVAL Aug 30 2025

Aug 30 2025