One-Stop Sourcing Guide: Integrated Solutions with Butterfly Valves, Mating Flanges, and Actuators

For small and medium-sized enterprises, sourcing industrial components can be a fragmented and complex process. JRVAL simplifies this by offering a complete, factory-direct package: a high-quality butterfly valve, perfectly matched flanges, and a reliable actuator. This integrated approach is only possible because we are a source butterfly valve factory with full control over casting, machining, and assembly.

The JRVAL Advantage: Excellence from Foundry to Final Assembly

Unlike distributors or assemblers, we are one of the few manufacturers of butterfly valves that truly controls the entire production chain. This vertical integration is the foundation of our quality promise and competitive pricing.

OUR 11 PRECISION CNC MACHINING CENTERS

CNC Center 1

CNC Center 2

CNC Center 3

CNC Center 4

CNC Center 5

CNC Center 6

CNC Center 7

CNC Center 8

CNC Center 9

CNC Center 10

CNC Center 11

Precision butterfly valve machining is a cornerstone of our quality control.

Mastery in Casting and Materials

Our journey began in casting over 20 years ago. Our founder is a casting expert, and this deep-rooted knowledge ensures that every butterfly valve casting meets the highest material standards, whether it's a stainless steel butterfly valve, a cf8m butterfly valve, or a ductile iron butterfly valve. As a premier butterfly valve supplier china, we guarantee that the material composition for any ss butterfly valve or wcb butterfly valve adheres precisely to customer-specified standards like ASME valve, DIN valve, or GOST valve specifications. This control over raw materials is our first line of defense against defects and performance issues, making us a trusted china butterfly valve manufacturer.

Precision Valve Machining and Assembly

Our advantage continues in our state-of-the-art workshop where every component undergoes meticulous CNC butterfly valve machining. We practice a "special standards for special supply" philosophy, meaning the dimensions of our butterfly valve parts are precisely engineered for a perfect fit, which is crucial for performance and longevity. This applies to every style, including the lug type butterfly valve, wafer butterfly valve, and the double flanged butterfly valve. The final butterfly valve assembly is not just about putting pieces together; it's a calibrated process ensuring that every handle butterfly valve and actuated butterfly valve functions flawlessly from day one.

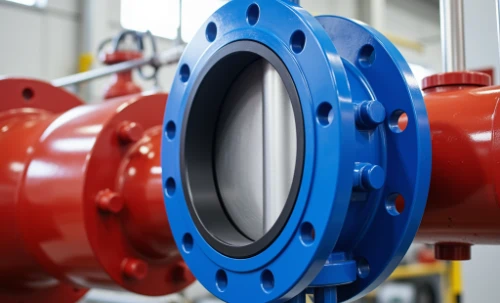

The Heart of Your System: Choosing the Right Butterfly Valve

Our portfolio is designed to meet diverse industrial needs. We don't just offer standard products; we provide engineered solutions, including our patent valve designs that redefine performance benchmarks.

Innovative Bi-Directional Zero-Leakage Sealing

A key JRVAL innovation is achieving bi-directional, zero-leakage performance even in our soft-seated valves. While a triple eccentric butterfly valve is known for this, we've re-engineered the structure of our centerline valve and double eccentric butterfly valve models to provide the same bubble-tight shutoff without added cost. This makes our resilient seated butterfly valve with an EPDM seat butterfly valve or PTFE seat butterfly valve a high-performance, cost-effective choice for applications in HVAC, water, and beyond. Whether you need a teflon lined butterfly valve or a rubber lined butterfly valve, we deliver exceptional sealing. This is a significant advantage over a standard offset butterfly valve.

A Comprehensive Range of Valve Types and Styles

Understanding the application is key, whether the discussion is gate valve vs butterfly valve or wafer vs lug type butterfly valve. We provide a full spectrum of options:

- Body Styles: We offer the compact wafer type butterfly valve (also called wafer style or wafer butterfly), the robust lug type butterfly valve (including fully lugged butterfly valve and semi lugged butterfly valve options), and the high-integrity double flanged butterfly valve for critical connections. We provide detailed lug type butterfly valve bolt chart data for easy installation.

- Performance Tiers: Our range includes the versatile concentric center line butterfly valve, the durable high performance butterfly valve (HPBV) or double offset butterfly valve, and the severe-service triple offset butterfly valve (also known as tri eccentric butterfly valve). Each type butterfly valve is designed for specific pressure and temperature ratings, like a class 150 butterfly valve or a PN16 butterfly valve.

- Materials: From a standard ss 304 butterfly valve to a high-grade ss316 butterfly valve, our material options cover a vast array of industrial applications. The stainless steel butterfly is a popular choice for its corrosion resistance.

- Sizes: We manufacture a complete range of sizes, including the popular 4 inch butterfly valve, 6 inch butterfly valve, 8 inch butterfly valve, and up to a large diameter 24 inch butterfly valve.

Completing the Assembly: Flanges and Actuators

A valve's performance is only as good as its installation and operation. By providing the full package, we eliminate compatibility issues and streamline your procurement process.

Mating Flanges

We supply the correct butterfly flange for your specific valve and pipeline standard. Sourcing a wholesale butterfly valve flange from us ensures a perfect match, preventing leaks and installation headaches for your flange butterfly valve assembly.

Actuation Devices

From a simple butterfly valve lever to a complex air actuated butterfly valve, we have the right operator. Our options include the butterfly valve with handle (lever operated butterfly valve), the high-torque butterfly valve with worm gear, and fully automated pneumatic and electric actuators.

Why an Integrated Solution Matters for Your Business

For SMEs aiming for high-quality systems without the premium price tag of major brands, our one-stop solution offers tangible benefits.

- Guaranteed Compatibility: When you source the valve, lug flange, and pneumatic actuator from us, you eliminate the risk of mismatched components. Every part, from the butterfly valve components to the actuator mounting, is designed to work together seamlessly.

- Streamlined Procurement: Reduce administrative overhead by dealing with a single, reliable china butterfly valve supplier. One purchase order, one shipment, and one point of contact for technical support.

- Optimized Cost-Performance: As a butterfly valve factory, we offer pricing that is competitive against major brands without sacrificing quality. You get a high performance valve solution at a price point that makes sense for your budget.

- Expert Support: Leverage our 20 years of expertise. We provide more than just products; we offer consultation to ensure you receive the best possible industrial butterfly valve package for your specific application, whether it's for a wafer check valve line or a complex process system.

Ready to Simplify Your Procurement?

Get a quote for your complete butterfly valve package.

JRVAL

JRVAL Aug 16 2025

Aug 16 2025