Butterfly Valve Longevity: Low-Price Procurement vs. Long-Term Costs, How to Avoid Pitfalls?

For small and medium-sized enterprises (SMEs), the appeal of a low-cost butterfly valve is undeniable. However, this initial saving often conceals a much higher total cost of ownership. Understanding the difference between a low price tag and long-term value is crucial to avoiding operational pitfalls, costly downtime, and safety hazards.

The Hidden Dangers Lurking in a Low Price Tag

When a butterfly valve price seems too good to be true, it usually is. The compromises made to achieve that price point directly impact the valve's performance, safety, and lifespan, leading to significant long-term expenses.

The Risks of Low-Cost Procurement

- Premature Failure: Substandard materials and poor butterfly valve casting lead to cracks, porosity, and structural weakness, causing catastrophic failure under pressure.

- Constant Leakage: Inaccurate valve machining and low-grade seals (like a faulty epdm seat butterfly valve) mean the valve cannot achieve a proper shutoff, leading to process contamination and wasted media.

- Operational Disruption: A single failed 6 inch butterfly valve can shut down an entire production line, resulting in hours or days of lost revenue that far exceeds the initial "savings."

- Increased Maintenance: Poorly made butterfly valve components wear out quickly, requiring frequent repairs and replacements, which inflate labor and inventory costs.

- Safety Hazards: A valve that fails unexpectedly can cause serious injury to personnel and damage to surrounding equipment, creating liability issues.

The Benefits of Long-Term Value

- Operational Reliability: A high-quality industrial butterfly valve, such as a double eccentric butterfly valve, performs consistently, ensuring process stability.

- Extended Service Life: Superior materials and precision engineering mean the valve lasts significantly longer, reducing the frequency of replacement.

- Lower Total Cost of Ownership: The initial investment is offset by minimal maintenance, zero unplanned downtime, and enhanced operational efficiency.

- Guaranteed Performance: Reputable butterfly valve manufacturers provide products that meet stringent standards like API 609, ensuring predictable and reliable operation.

- Peace of Mind: Investing in a quality valve from a trusted china butterfly valve supplier means you can focus on your core business, not on fixing faulty components.

The JRVAL Difference: Building Longevity from the Ground Up

True valve quality isn't just about final assembly; it begins in the foundry. At JRVAL, we are a genuine source butterfly valve factory, controlling every critical stage of production. This vertical integration is our—and your—greatest advantage.

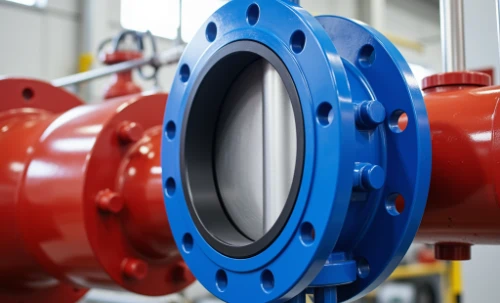

Quality control starts with the raw material. A robust WCB or CF8M butterfly valve begins with superior casting.

1. Casting as the Cornerstone: A Foundation of Integrity

Many suppliers are merely assemblers. We started as a foundry, and our owner is a casting expert with over 20 years of hands-on experience. This deep expertise in butterfly valve casting is non-negotiable for quality. We guarantee that the material for every single valve—whether it’s a standard carbon steel butterfly valve or a specialized ss316 butterfly valve—strictly adheres to the customer's specified standards (e.g., ASME, DIN). This eliminates the risk of hidden defects that plague lower-cost alternatives and ensures every valve body, from a small 2 inch butterfly valve to a large diameter butterfly valve, is flawless.

2. Precision Machining: The Key to a Perfect Seal

A superior casting is only as good as its machining. Our facility is equipped for specialized, high-precision cnc butterfly valve machining. This is one of our core strengths. Every component, especially the butterfly valve disc machining and seat interface, is machined to exact tolerances. This precision ensures a perfect fit, bubble-tight sealing, and low, consistent operating torque. It's the difference between a wafer type butterfly valve that leaks after a few cycles and one that provides years of reliable service. This dedication to precision applies across our entire product line, from a simple lever operated butterfly valve to a complex triple offset butterfly valve.

3. Innovative Engineering: Smarter Design, Not Higher Costs

Our control over the entire manufacturing process allows us to innovate. A prime example is our ability to achieve bi-directional, zero-leakage sealing on our soft-seated valves, including standard concentric and double offset butterfly valve models. Through intelligent structural enhancements, not by adding costly components, we deliver this high-performance feature at no extra cost. This is a direct benefit of partnering with a true butterfly valve factory that understands valve engineering from the inside out.

How to Choose a Reliable Butterfly Valve Supplier

To avoid the pitfalls of low-cost procurement, you need to vet your suppliers properly. Move the conversation beyond price and ask the questions that reveal a manufacturer's true capabilities.

Key Questions to Ask Any Potential Supplier:

- Manufacturing Control: "Do you own and operate your own foundry for butterfly valve casting, or do you outsource it?" A source factory has far greater quality control.

- Material Certification: "Can you provide mill test reports (MTRs) for the specific materials used in my order, such as for a stainless steel butterfly valve?" Traceability is key to ensuring quality.

- Machining Standards: "What are your machining tolerances for critical valve components like the stem and disc? Do you perform 100% dimensional inspection?" This separates the precision manufacturers from the rest.

- Testing and Compliance: "What pressure testing standards do you follow (e.g., API 598)? Can you certify your valves to international standards like API 609 or ISO 5752?" Reputable manufacturers will have robust testing protocols.

- Range of Expertise: "Can you supply different configurations like a lug type butterfly valve, a flanged butterfly valve, or a pneumatic butterfly valve with a specific actuator?" A wide range of offerings often indicates deeper engineering knowledge.

At JRVAL, we welcome these questions. Our answer is simple: we control the entire process. We offer the engineering, quality assurance, and reliability of a major brand because we are the source factory, with a pricing structure that provides exceptional value for SMEs who cannot afford to compromise on quality.

Invest in Reliability with JRVAL Solutions

Partner with a butterfly valve manufacturer that prioritizes longevity and performance. Explore some of our solutions designed for demanding industrial applications.

High-Performance Valves (HPBV)

Our double offset butterfly valve (or high performance valve) is engineered for longer life and superior sealing in higher pressure and temperature applications. A smart upgrade from standard valves.

Explore HPBV

Lug and Wafer Type Valves

The workhorses of the industry. Our lug type butterfly valve and wafer style models benefit from our superior casting and machining, ensuring reliable installation and service.

View Body Styles

Stainless Steel Butterfly Valves

For corrosive environments, our ss butterfly valve and other alloy valves provide exceptional durability, with guaranteed material integrity from our own foundry.

See Material OptionsReady to Discuss Long-Term Valve Solutions?

Our experts are here to help you reduce costs and improve reliability.

JRVAL

JRVAL Aug 26 2025

Aug 26 2025