Hidden Risks in Procurement Contracts

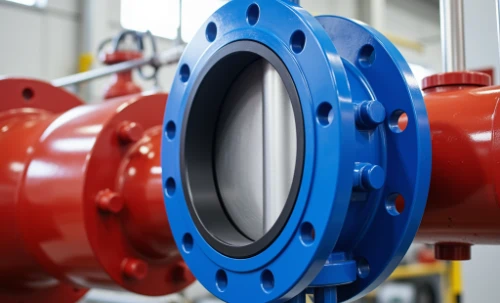

In industrial procurement, focusing solely on the price of a 4 inch butterfly valve or a 6 inch butterfly valve can be a costly mistake. For critical components like an industrial butterfly valve, the true cost of ownership is revealed in the fine print. This article deciphers these complexities and highlights how partnering with a true china butterfly valve manufacturer like JRVAL provides the security you need.

The Warranty Maze: More Than Just a Timeframe

A warranty for a high performance butterfly valve (HPBV) or even a standard water butterfly valve appears straightforward, but the details in the valve butterfly contract are critical. A vague clause can leave you unprotected when your double offset butterfly valve fails.

The integrity of every internal component is the foundation of a reliable product and a meaningful warranty.

- Pitfall 1: Vague "Defect" Definitions: A reliable warranty for a teflon lined butterfly valve should clearly define "manufacturing defect," distinguishing it from normal wear on components like an epdm seat butterfly valve. Without this, a supplier might deny a claim for a leaking metal seated butterfly valve, blaming "operational conditions" when the issue is poor butterfly valve casting.

- Pitfall 2: The Warranty Clock: Does the warranty on your pvc butterfly valve start from shipment or installation? A wafer type butterfly valve might sit in storage for months. A shipment-based warranty could expire before the valve butterfly wafer is commissioned.

- Pitfall 3: The Burden of Proof: Investigating a failed sanitary butterfly valve can be complex. Some contracts require costly third-party analysis, placing a heavy burden on the buyer. A trustworthy butterfly valve supplier china should offer a fair claims process for every type butterfly valve they sell.

- The Foundation of a Strong Warranty: A robust warranty reflects the manufacturer's confidence, which stems from controlling the entire production process. Our 20-year expertise in casting ensures the material integrity of every wcb butterfly valve body. From there, precision valve machining and meticulous butterfly valve assembly create a product, whether it's a lug butterfly valve or a double flanged butterfly valve, that is built to last. This commitment applies to our entire range, from a simple centerline valve to a complex triple eccentric butterfly valve.

The After-Sales System: Separating Promises from Performance

An impressive after-sales promise for a pneumatic butterfly valve is worthless without a robust system. When a critical actuated butterfly valve fails, you need an expert partner, not just an email address.

Effective after-sales support requires deep technical knowledge of every valve type and application.

- Response Time vs. Resolution Time: How quickly will you get a reply about your gear type butterfly valve versus how quickly will the problem be solved? A distributor may respond quickly but then must relay information back to the original butterfly valve manufacturers, causing delays.

- Technical Expertise: Can the support team understand a butterfly valve diagram, advise on lug type butterfly valve installation, or provide the correct butterfly valve cap screw chart? Access to genuine engineering knowledge, distinguishing between a gate valve vs butterfly valve application, is crucial.

- Availability of Spares: If you need a new seat ring for butterfly valves for a 10 inch butterfly valve, or a replacement disc for a 12 inch butterfly valve, how long is the wait? Long lead times for essential butterfly valve parts or butterfly valve components can halt production.

- The Manufacturer's Edge: As a source butterfly valve factory, our after-sales support is a direct line to the experts. Whether you have a simple lever operated butterfly valve or a sophisticated triple offset butterfly valve, our team provides in-depth assistance. We are not just a seller; we are among the leading manufacturers of butterfly valves in the region. We can even provide guidance on the differences like lugged vs wafer butterfly valve.

The Source Factory Advantage: Mitigating Risk from Day One

The best way to avoid contractual risks with your butterfly valve valve is to choose a partner whose quality and engineering excellence minimize failure. This is the advantage of working with a source factory.

Uncompromised Material Control

The performance of a stainless steel butterfly valve (ss butterfly valve) starts with quality casting. We guarantee that materials for every valve butterfly, from a butterfly valve ss316 to a cf8m butterfly valve, meet or exceed standards like api 609 butterfly valve or din valve.

Precision and Innovation

Our commitment to precision cnc butterfly valve machining delivers superior accuracy. This allows us to innovate. We've re-engineered our concentric butterfly valve (center line butterfly valve) and double eccentric butterfly valve models to achieve bi-directional zero-leakage, a feature often exclusive to a more expensive triple offset valve, without extra cost. This is the capability of a true china butterfly valve factory.

From Wafer to Lug and Beyond

Whether your application calls for a wafer butterfly valve, a semi lugged butterfly valve, a full lug butterfly valve, or a butterfly valve flange type, a source factory provides consistency. We manage every step, from butterfly valve disc machining to the final test of a pn16 butterfly valve. We offer both lug and wafer type butterfly valve configurations to suit any need.

Choose a Partner Invested in Your Success

Choosing a butterfly valve supplier is a long-term strategic decision. Looking past the initial price of a 2 inch butterfly valve to scrutinize the warranty for your high temperature butterfly valve and after-sales support can save your business. Partnering with a source factory like JRVAL means investing in quality—from the casting of the lug valve body to the final butterfly valve assembly. It’s the assurance that comes from knowing your china butterfly valve supplier stands behind every product.

Resilient Seated Valves

The ideal, cost-effective solution for water, HVAC, and general industrial services requiring reliable, bubble-tight shutoff.

View Concentric Valves

High-Performance Valves

Engineered with a double offset design for longer life and superior sealing in higher pressure and temperature applications.

View Offset Valves

Full Butterfly Valve Catalog

Explore our complete range, including triple offset, lined, and custom-engineered valves for any industrial challenge.

Explore CatalogMinimize Your Procurement Risk

Our experts are ready to help you find the perfect valve solution.

JRVAL

JRVAL Aug 16 2025

Aug 16 2025