JRVAL Quality Control Flow Chart

Carbon Steel Butterfly Valve Production Process - 20 Years of Casting Experience Ensures Valve Body and Disc Blank Quality

Carbon Steel Butterfly Valve Production Quality Control Process

- With water glass and silica sol 3 casting lines

- 20 years of casting experience ensures the quality of blank of valve body and disc

- We own full range of mold

- Above 10 materials are available, such as WCB, LCB, LCC etc.

- Spectrometer material test ensures metal elements meet with standard

- Use sand shaker which enables sand cleaning quickly and thoroughly

- Protect the casting surface to avoid any damage

- Hook shot blasting machines and crawler shot blasting machine will do sand-blasting to the valve body and disc

- Removed the surface oxide skin of valve body and disc

- Then put into storage prepare for machining and valve assemble

- Regularly inspect tooling and equipment to ensure the accuracy

- Inspector check quality strictly

- The unqualified products either be repaired or disposed

- Check the processing standard of the outer edge R-Arc height and the end face dimension

- The unqualified products either be repaired or disposed

- Rubber Parts: Valve seat and O-ring are purchased through outsourcing

- Sampling inspection on the coaxiality of the valve seat and valve disc

- Inspection report must be provided before purchasing to ensure stable quality and performance

- Metal Parts: Screw, bolt, nut and other accessories like electric actuator and pneumatic actuator are purchased through outsourcing

- Cooperated with us many years like brother or sister companies, quality is assured

- Valve Assemble: Collect valves parts strictly based on picking list

- Assemble according to flow chart and rules

- Standardize the assembly and test to ensure valves with zero-leakage

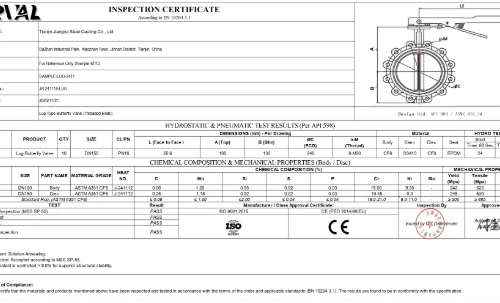

- Pressure Test: Valve pressure test based on 1.25 times of nominal pressure

- 10 minutes hydraulic test with intelligent tester to ensure the sealing surface no leakage

- A stable value of the pressure gauge is regarded as qualified product

- Must be repaired for any leakage until reaches zero leakage standard

- Take record of the inspection value then storage for delivery

Behind the Scenes: Advanced Casting & Machining

Quality isn't just inspected; it's manufactured. Discover how we achieve +30% stress resistance and 0ppm leakage.

JRVAL

JRVAL Dec 22 2025

Dec 22 2025