Lug vs. Wafer: The Definitive Butterfly Valve Comparison

Choosing between a lug and wafer butterfly valve impacts installation, maintenance, and system safety. This expert guide breaks down every critical difference to ensure you select the optimal valve for your application and budget.

Guide Navigation

The Core Concept: Connection Style Defines Function

Wafer Style

Quick Analogy: A picture frame "sandwiched" between two panes of glass. It's held in place only by the clamping force of the entire assembly.

A cost-effective design that fits between two pipe flanges. The valve is held in place by long bolts or studs that run from one flange to the other, clamping the valve body in between.

Key Principle: Held by system compression.

Lug Style

Quick Analogy: A picture frame with its own screw holes, bolted directly to the wall. It can be removed without the wall falling down.

A more robust design featuring threaded inserts ("lugs") in the valve body. This allows bolts to connect each pipe flange directly to the valve, independent of the other flange.

Key Principle: Direct, independent bolting.

Installation Method: A Visual Comparison

Wafer Valve Installation

[A video showing a wafer valve held between two flanges by long through-bolts and nuts that span the entire assembly.]

Lug Valve Installation

[A video showing a lug valve with short cap screws being threaded from each flange into the valve's own tapped holes.]

Anatomy & Construction: The Hole & Lug is the Difference

Wafer Valve Anatomy

Wafer style butterfly valve highlighting its smooth body with alignment holes

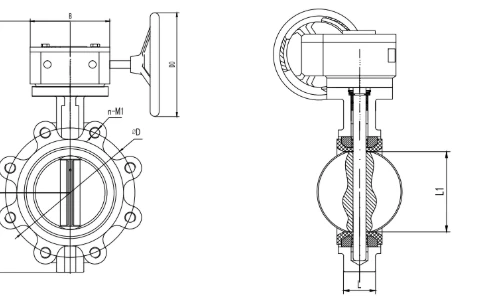

Lug Valve Anatomy

Lug style butterfly valve highlighting its threaded lugs for bolting

The Definitive Decision Matrix

This detailed, data-driven comparison breaks down every critical performance factor to declare a winner for each specific engineering requirement.

Dead-End Service Capability

The ability to remain sealed at full pressure when the downstream flange is removed (e.g., for pump maintenance).

Wafer Style

Cannot be used. Removing one flange eliminates the clamping force, causing immediate seal failure.

Lug Style

Specifically designed for this. It remains securely bolted to the upstream flange, providing safe isolation.

Initial Cost (CAPEX)

The initial purchase price of the valve itself. This is the primary driver for many budget-focused projects.

Wafer Style

Significantly lower cost due to a simpler body design, less material, and less machining required.

Lug Style

Higher cost due to the complex manufacturing of the threaded lugs and a heavier, more robust body.

Maintenance & System Downtime

Ease of servicing downstream equipment and the valve itself, which directly impacts operational availability.

Wafer Style

Poor. To service anything, the entire line segment must be shut down and drained. High operational cost.

Lug Style

Excellent. Allows downstream piping to be removed while the valve holds pressure, drastically reducing downtime.

Total Cost of Ownership (TCO)

Considers initial cost plus long-term operational costs like maintenance, downtime, and labor.

Wafer Style

Low initial cost, but can lead to very high TCO in systems requiring frequent maintenance due to extended downtime.

Lug Style

Higher initial cost is often offset by massive savings in reduced downtime and labor, leading to a lower TCO in critical systems.

Installation & Alignment

The level of precision and effort required to correctly position the valve during installation, affecting labor time and risk of seat damage.

Wafer Style

More difficult. Requires careful positioning while bringing flanges together. Higher risk of seat damage if misaligned.

Lug Style

Easier and safer. The valve can be bolted to one flange first, ensuring perfect alignment before the second flange is attached.

Bolting & Integrity

The method of securing the valve and its resilience to thermal cycles and vibration.

Wafer Style

Uses fewer, longer bolts. More susceptible to loosening from vibration and uneven tension from thermal expansion/contraction.

Lug Style

Uses twice as many shorter bolts. This creates a more rigid, secure, and redundant connection that better resists vibration and thermal stress.

How to Make the Final Choice

Use this simple checklist to make a confident and correct decision based on your specific project requirements.

Choose a WAFER Valve if...

- Cost is the primary driver. Wafer valves offer the same in-line performance for a lower initial price.

- The valve will **always** be installed between two pipe flanges (standard in-line service).

- The system can be **fully shut down and drained** for any valve or equipment maintenance.

- **Weight and space are at an absolute premium**, such as in OEM skid manufacturing.

Choose a LUG Valve if...

- The valve is needed for **"dead-end service"** (e.g., at the end of a line or isolating pumps/tanks).

- **Safety and maintenance time** are critical. The isolation capability is a key operational advantage.

- The media is **toxic, corrosive, or high-temperature**, making system drainage hazardous or costly.

- The higher initial cost is justified by **significant savings in future maintenance downtime**.

Industry Application Showdown: 12 Scenarios, 1 Clear Winner

Theory is good, but practical application is everything. Here’s a breakdown of common industrial scenarios and the definitive choice for each.

Pump & Equipment Isolation

Non-negotiable. The ability to safely isolate a pump or filter for maintenance without draining the entire system makes the lug valve the only correct choice here. It pays for itself in saved downtime.

General HVAC & Water Lines

In standard building services where the valve is always in-line and cost is a primary factor, the wafer style is the default. Its lower price and weight offer significant advantages in large-scale installations.

End-of-Line Service

When a valve is needed at the end of a pipe run, for example, at a tank drain or a discharge point, only a lug valve can be used. A wafer valve has no downstream flange to clamp against.

Skid-Mounted & OEM Systems

For original equipment manufacturers (OEMs) building compact, pre-fabricated systems, the wafer valve's lower weight, smaller profile, and reduced cost are highly advantageous for production and shipping.

Chemical Processing

When handling hazardous or toxic media, the ability to isolate sections for maintenance without draining large volumes of dangerous fluid is a critical safety requirement. Lug style is the only responsible choice.

Water & Wastewater Distribution

For long-distance municipal water transport or wastewater collection systems, valves are typically left in-line for years. The cost savings of wafer valves, multiplied by hundreds or thousands of units, are immense.

Marine & Shipbuilding

In the tight, vibration-prone spaces of a ship's engine room, both ease of maintenance and resistance to vibration are key. The lug valve's robust, independent bolting excels in these harsh conditions.

Fire Protection Systems

In sprinkler systems, valves are part of a large, cost-sensitive network. They are rarely serviced in a way that requires isolation. The wafer style provides the necessary UL/FM-approved performance at the lowest cost.

High Temperature / Steam

Thermal cycling causes pipe expansion and contraction, which can compromise the bolt tension on wafer valves. The lug style's more secure, redundant bolting provides superior reliability and safety in steam or hot fluid lines.

Food & Beverage Processing

In sanitary lines where full system clean-in-place (CIP) procedures are standard, the entire line is flushed anyway. The need for dead-end isolation is minimal, making the cost-effective wafer style a smart choice.

Mining & Slurries

Abrasive slurries cause high wear on valve seats and discs. Maintenance is frequent. A lug valve allows for rapid valve replacement or downstream pipe cleaning without draining vast, heavy, and messy slurry lines.

Agricultural Irrigation

Large-scale irrigation networks prioritize cost-effectiveness and simplicity above all else. The inexpensive and lightweight wafer style is perfectly suited for these low-pressure, non-critical applications.

Frequently Asked Technical Questions (FAQ)

Q: What exactly is "Dead-End Service"? Why is it so important?

A: Dead-end service is the ability of a valve to hold back the full system pressure from the upstream side while the downstream piping is completely removed. It is a critical safety and maintenance feature. Only lug-style valves are rated for this because they are bolted directly to the upstream flange and don't rely on a downstream flange for support. This allows maintenance crews to safely work on equipment like pumps or filters without shutting down and draining the entire system.

Q: Do lug and wafer valves have the same pressure rating?

A: Generally, for a given class (e.g., ASME Class 150), both lug and wafer valves are designed to handle the same in-line pressure when installed between two flanges. However, only the lug-style valve is rated to handle that pressure in a dead-end service configuration. A wafer valve's dead-end service rating is effectively zero.

Q: If a lug valve is better, why would anyone use a wafer valve?

A: The primary driver is cost. A wafer valve is significantly cheaper and lighter. In thousands of applications where the valve will only ever be used in-line (e.g., long water transport pipelines, HVAC systems), the dead-end service capability of a lug valve is an unnecessary and expensive feature. The choice is about selecting the right tool for the job to optimize both performance and budget.

Our Recommended Valve Solutions

Engineered for reliability and performance, our portfolio includes both lug and wafer valves to meet your exact specifications.

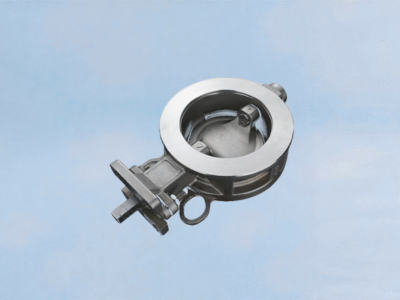

High-Quality Wafer Valve

The industry standard for cost-effective, reliable flow control in in-line applications. Lightweight, compact, and available in a wide range of materials.

View Wafer Valves

Dead-End Service Lug Valve

The definitive choice for safety and maintainability. Fully rated for dead-end service, enabling equipment isolation without system shutdown.

View Lug Valves

Full Butterfly Valve Catalog

Explore our complete range of butterfly valves, including high-performance, triple offset, and lined options for any industrial challenge.

Explore CatalogDon't Guess. Specify with Confidence.

Choosing the right connection type is a fundamental engineering decision. Our experts are ready to help you analyze your system's maintenance strategy and safety requirements to ensure you select the optimal valve that enhances both performance and operational efficiency.

Facing a Flange Dilemma?

We ensure perfect compatibility for your project.

JRVAL

JRVAL Aug 02 2025

Aug 02 2025