The Anatomy of a Butterfly Valve

Despite its simple operation, a butterfly valve consists of several primary components working in harmony. Explore them below with our interactive diagram.

The Core Components Explained

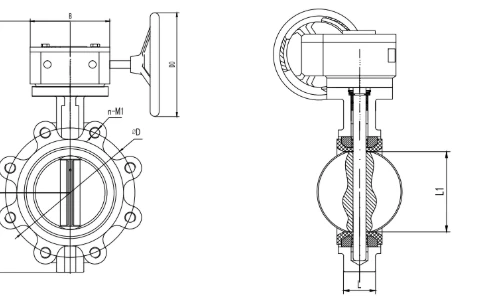

- Body: This is the main outer frame of the valve that fits between two pipe flanges. It houses and protects the internal components. The body comes in two main styles: Wafer (sandwiched between flanges) and Lug (bolted directly to flanges), which determines how it is installed in the pipeline.

- Disc: Often called the "butterfly," this is the component that controls flow. It sits in the center of the pipe and rotates 90 degrees to open or close the valve. The material and shape of the disc are critical for performance and media compatibility.

- Stem: The stem is the shaft that connects the disc to the actuator (e.g., a handle, gear, or automated controller). When the actuator is turned, the stem rotates the disc, opening or closing the valve.

- Seat: The seat is a liner, typically made of an elastomer (like EPDM or NBR) or a polymer (like PTFE), that lines the inner wall of the valve body. When the valve is closed, the disc presses firmly against the seat to create a leak-proof seal. In high-performance valves, the seat can be metal.

How Does a Butterfly Valve Work?

The working principle is elegantly simple, which is why these valves are so widely adopted for fast-acting applications.

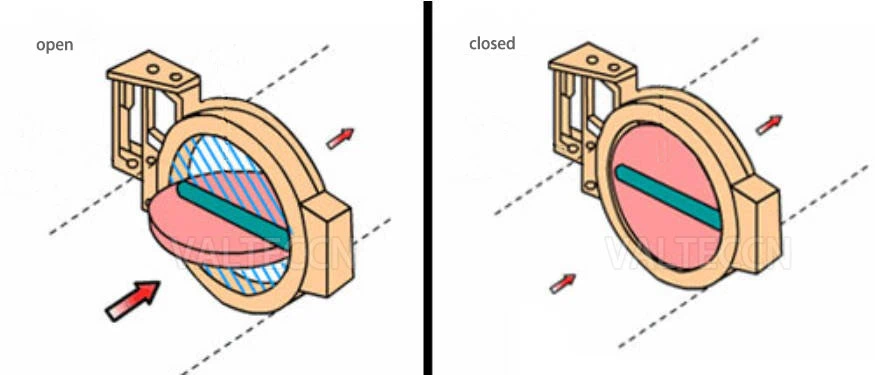

The disc rotates 90 degrees to move from fully closed to fully open.

【image source: https://www.valteccn.com/blog/butterfly-valve-article/how-do-i-know-if-the-manual-butterfly-valve-is-open-or-closed/]

A butterfly valve operates based on the quarter-turn principle. Think of it like a damper in an air duct.

- Closed Position: The disc is oriented perpendicular (at 90 degrees) to the flow, completely blocking the passageway. The edge of the disc is pressed tightly against the seat, ensuring a secure shutoff.

- Open Position: The actuator is turned 90 degrees, which rotates the stem and disc. The disc is now oriented parallel to the flow, allowing fluid or gas to pass through with minimal obstruction.

This quick, 90-degree action allows for very fast opening and closing, making butterfly valves ideal for applications requiring rapid shutdown or startup. They can also be used for throttling (regulating flow) by positioning the disc at an intermediate angle, although they are generally less precise for this task than a globe valve.

The 3 Major Types of Butterfly Valves

Not all butterfly valves are created equal. They are primarily categorized by the geometry of the disc and seat, which dictates their performance capabilities and suitable applications.

1. Concentric (Zero Offset)

This is the most basic design. The stem is centered in the middle of the disc, and the disc is centered in the bore of the valve. The seat is an interference-fit resilient liner. As the disc closes, it makes contact with the seat for about the last 10% of its rotation, which can cause wear over time. These are often called "resilient-seated" or "rubber-seated" valves.

- Best For: General service, low-pressure water, air, and applications where bubble-tight shutoff is needed but the media is not abrasive or high-temperature.

2. Double Offset (High-Performance)

This design features two offsets. First, the stem is offset from the centerline of the disc. Second, the stem is offset from the centerline of the valve bore. This "double offset" geometry creates a cam action as the disc closes. The disc only contacts the seat for the last few degrees of rotation, drastically reducing friction and wear.

- Best For: Higher pressure and temperature applications, light slurries, and situations requiring longer service life and more reliable sealing than concentric valves.

3. Triple Offset

The premium design for critical applications. In addition to the two offsets of the double offset valve, there is a third offset in the geometry of the seating surface, creating a conical sealing profile. This design completely eliminates friction between the disc and seat during operation. The seal is achieved by metal-on-metal or laminated graphite/metal seating, providing a bubble-tight, zero-leakage shutoff.

- Best For: Severe service applications, including high temperatures, high pressures, corrosive media, cryogenics, and steam service.

Advantages and Disadvantages

Understanding the trade-offs is crucial for proper valve specification.

Advantages

- Lightweight & Compact: Significantly smaller footprint and lower weight compared to other valve types like gate or globe valves.

- Low Cost: Simpler design and less material make them one of the most economical valve choices.

- Fast Acting: The 90-degree turn allows for very rapid opening and closing.

- Low Pressure Drop: When fully open, the thin disc offers little resistance to flow.

- Versatility: Available in huge sizes and a wide range of materials for diverse applications.

Disadvantages

- Limited Throttling: Prone to turbulence and cavitation in throttling applications near the closed position.

- Disc in Flow: The disc is always present in the flow path, causing a minor pressure drop even when fully open.

- Seal Wear: In basic concentric designs, the seat can be susceptible to wear from the disc.

- High-Torque Potential: In certain conditions (high pressure drop), the torque required to operate the valve can be high.

Common Uses & Applications of Butterfly Valves

Thanks to their versatility and cost-effectiveness, butterfly valves are trusted across a vast range of industries for both simple on/off functions and complex process control.

Butterfly valves are a common sight in industrial facilities worldwide.

- HVAC (Heating, Ventilation, and Air Conditioning): This is a primary market for butterfly valves. They are used in chiller isolation, cooling tower lines, and hot water systems due to their compact size, low cost, and fast operation.

- Water & Wastewater Treatment: From municipal water distribution to wastewater treatment plants, butterfly valves are used for flow isolation and control in large-diameter pipelines. Their ability to handle some solids makes them suitable for raw water intake and effluent lines.

- Chemical Processing: For handling corrosive or aggressive media, specialized butterfly valves (e.g., PTFE-lined or made from exotic alloys) are used. High-performance double and triple offset valves are common here for reliable, long-term sealing.

- Food & Beverage: Sanitary butterfly valves, made with polished stainless steel and FDA-approved seal materials (like silicone), are used extensively for flow control in hygienic processes like brewing, dairy production, and beverage filling lines.

- Power Generation: Power plants use large butterfly valves in cooling water circuits (CCW systems) and flue gas desulfurization (FGD) systems. Triple offset valves are often specified for high-temperature steam applications.

- Shipbuilding & Marine: The lightweight and space-saving nature of butterfly valves makes them ideal for ballast systems, engine room cooling, and fire-fighting systems on ships and offshore platforms.

- Bulk Solids Handling: In industries like cement and grain processing, butterfly valves are used to control the flow of powdered or granular materials from hoppers and silos.

Explore Our Butterfly Valve Solutions

From general utility to severe service, we provide a complete range of butterfly valves engineered for performance and reliability.

Resilient Seated Valves

The ideal, cost-effective solution for water, HVAC, and general industrial services requiring reliable, bubble-tight shutoff.

View Concentric Valves

High-Performance Valves

Engineered with a double offset design for longer life and superior sealing in higher pressure and temperature applications.

View Offset Valves

Full Butterfly Valve Catalog

Explore our complete range, including triple offset, lined, and custom-engineered valves for any industrial challenge.

Explore CatalogHave a Question About Butterfly Valves?

Our experts are ready to help you find the perfect solution.

JRVAL

JRVAL Aug 02 2025

Aug 02 2025