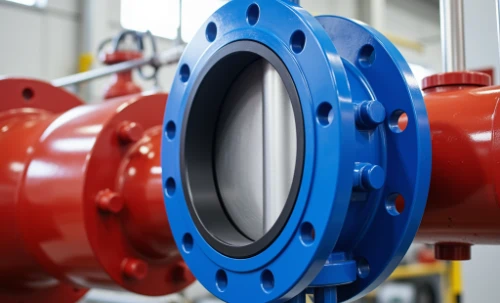

Regional Water Quality Differences: How to Choose Butterfly Valve Materials Based on Procurement Environment?

In the world of fluid control, not all water is created equal. Regional variations in chemical composition, salinity, and temperature can dramatically affect the lifespan and reliability of your industrial butterfly valve. Making an informed material choice based on the procurement location is critical to ensuring operational efficiency and avoiding premature failure.

Understanding Key Water Quality Factors

Before selecting a butterfly valve, it's essential to understand the medium it will control. The primary characteristics of water that influence material degradation include:

The chemical makeup of water in piping systems dictates the required valve material specifications.

- Salinity and Chlorides: Coastal and marine environments present a significant challenge due to high salt content, which is extremely corrosive to standard carbon steel and even some lower-grade stainless steels. A suitable marine butterfly valve is essential here.

- pH Levels: Highly acidic or alkaline water can aggressively attack valve components. This degradation can compromise the integrity of both the valve body and the crucial seat ring for butterfly valves, leading to leaks.

- Mineral Content (Hardness): Water with high levels of calcium and magnesium can cause scaling on the butterfly valve disc machining surfaces and seat, impeding the valve's ability to close and achieve a tight seal.

- Disinfectants and Chemicals: Water treatment facilities often use chemicals like chlorine, which can degrade elastomeric materials like a standard rubber seat butterfly valve over time, making material compatibility a key consideration.

- Abrasives and Suspended Solids: Raw water intake or wastewater applications often contain sand, silt, or other solids. This requires a robust butterfly valve design, potentially a metal seated butterfly valve or a high performance butterfly valve, to resist erosion.

Matching Butterfly Valve Materials to Your Environment

Selecting the right combination of body, disc, and seat materials is paramount. Here is a general guide from a leading butterfly valve supplier for common scenarios:

For Municipal and Fresh Water Systems (Low Corrosivity)

In standard HVAC butterfly valve or potable water applications, the primary goal is reliability and cost-effectiveness. A popular choice is a wafer type butterfly valve or lug style butterfly valves.

- Body Material: Epoxy coated butterfly valves with a cast or ductile iron body offer excellent protection at an economical price point.

- Disc Material: A stainless steel butterfly valve disc (typically butterfly valve ss304 or ss316) provides sufficient corrosion resistance. Nylon coated discs are also a viable option.

- Seat Material: An EPDM seat butterfly valve is the industry standard for water applications, offering excellent durability and sealing. This configuration is common for a resilient seated butterfly valve.

For Seawater, Brackish Water, and High-Chloride Environments

These applications demand superior corrosion resistance for every wetted butterfly valve part. The difference between lug and wafer butterfly valve connection types becomes less important than the material itself.

- Body and Disc: Materials must be upgraded. Options include a full stainless steel butterfly valve (butterfly valve stainless) or specialized alloys. For discs, Duplex, Super Duplex, or at least a cf8m butterfly valve (SS316) is necessary to prevent pitting.

- Seat Material: While EPDM is suitable, Viton (butterfly valve viton seat) should be considered if other chemicals are present. The selection must ensure the entire actuated butterfly valve assembly is protected.

For Chemically Treated or Aggressive Industrial Water

When dealing with process water containing corrosive chemicals, protection becomes the top priority. A high performance valve like a double offset butterfly valve may be required.

- Lined Valves: A teflon lined butterfly valve or ptfe lined butterfly valve provides a complete barrier against the medium. These valves, featuring a butterfly valve ptfe seat, are ideal for the most aggressive applications.

- High-Alloy Valves: For extreme temperature and corrosive combinations, exotic materials like Hastelloy are used, often in a triple eccentric butterfly valve design for zero-friction sealing.

The JRVAL Difference: Source Factory Control for Unmatched Reliability

Knowing which materials to choose is only half the battle. Ensuring those materials are authentic and manufactured to the highest standards is what truly guarantees performance. As a source butterfly valve factory, JRVAL provides this assurance through complete vertical integration.

1. Master Founders and Guaranteed Materials

The foundation of any durable valve butterfly valve is its casting. JRVAL began as a foundry 20 years ago, led by a regionally renowned casting expert. This heritage means we guarantee that every butterfly valve casting, whether it's a WCB butterfly valve or a stainless steel wafer butterfly valve, meets precise metallurgical standards. We ensure the material integrity required to withstand your specific regional water challenges.

2. Precision Machining for Flawless Operation

Performance depends on precision. Our advanced cnc butterfly valve and valve machining capabilities ensure that all butterfly valve components meet exacting tolerances. This is particularly evident in our lug type butterfly valve, where high-precision threaded holes on the butterfly lug make for easy, trouble-free lug type butterfly valve installation, a critical advantage for maintenance teams.

3. Integrated Quality Control from Start to Finish

As one of the leading manufacturers of butterfly valves in China, JRVAL oversees the entire production process from raw material casting to final butterfly valve assembly and testing. This end-to-end control ensures that whether you order a 4 inch butterfly valve or a large diameter butterfly valve, the quality is consistent and verifiable. We are a butterfly valve factory that takes full responsibility for our product.

4. Custom Standards and Innovative Sealing

We understand that global projects require adherence to multiple standards like API 609 butterfly valve, DIN valve, or JIS butterfly valve. Our flexible manufacturing allows us to produce different standards in a single batch. Furthermore, our innovative bi-directional, zero-leakage seal is a standard feature on our soft-seated centerline valve and double eccentric butterfly valve models—a structural enhancement that provides premium performance without the premium cost associated with a triple offset valve.

Explore Our Butterfly Valve Solutions

JRVAL offers a complete range of butterfly valves engineered for performance and reliability, tailored to your specific environmental needs. Whether you need a manual butterfly valve or a pneumatic butterfly valve, we have a solution.

Resilient Seated Valves

The ideal, cost-effective solution for municipal water, HVAC, and general industrial services requiring reliable, bubble-tight shutoff. Available in both wafer and lug styles.

View Concentric Valves

High-Performance Valves

Engineered with a double offset butterfly valve design for longer life and superior sealing in higher pressure, temperature, and abrasive applications.

View Offset Valves

Full Butterfly Valve Catalog

Explore our complete range, including flange butterfly valve models, triple offset, lined, and custom-engineered solutions for any industrial challenge.

Explore CatalogNeed Help Selecting the Right Valve Material?

Our experts are ready to help you find the perfect solution for your environment.

JRVAL

JRVAL Aug 21 2025

Aug 21 2025