The Challenge: The "Mystery" of the Leaking Valves

Our Korean client was facing a persistent headache with their water trucks. During operation, specific conditions created a reverse pressure (negative pressure) of approximately -0.01 MPa within the piping system.

While this pressure seems minor, it was enough to cause failure in standard knife gate valves. Most conventional valves are designed for uni-directional pressure. When faced with this reverse suction, the valve plate would pull away from the seal, resulting in water leakage. This wasted resources and led to safety concerns.

They needed a solution that was durable and maintained performance standards, avoiding issues often discussed in valve leakage class standards.

The Solution: True Bi-Directional Sealing

Unlike trading companies that simply sell what is in stock, as a source factory with full-process control, we didn't just offer a replacement; we engineered a solution.

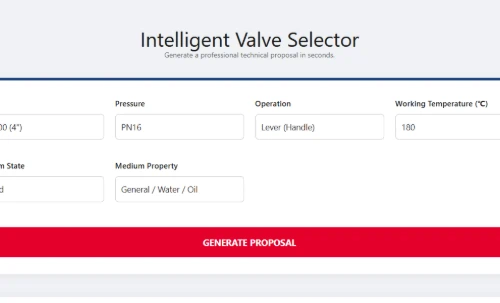

Upon receiving the technical parameters, JRVAL engineering team identified that the standard sealing structure could not withstand the vacuum effect. We proposed our Optimized Bi-Directional Knife Gate Valve:

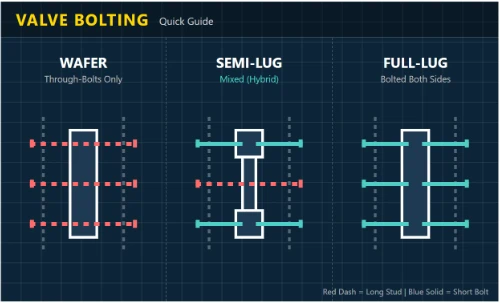

- Structural Optimization: We adjusted the wedge and seat design to ensure the valve plate remains tightly compressed against the seal, even when pressure pulls from the opposite direction.

- Zero Leakage: We utilized high-grade EPDM seals and precision-machined gates to ensure a Class-A zero leakage performance, whether installed forward or backward.

The Factory Advantage: Why We Could Do It

This solution was made possible because we control every step of the manufacturing process:

In-House Casting

We modified the valve body casting mold to accommodate the structural reinforcement needed.

Precision Machining

Our CNC machining centers ensured the tolerance was tight enough to handle pressure fluctuations.

Assembly & Testing

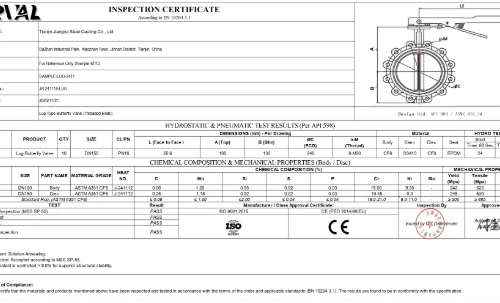

Every valve underwent strict bi-directional pressure testing, backed by our 3.1 inspection certificate standards.

The Result

The client installed our customized knife gate valves on a test fleet of water trucks. The result? Zero leakage. The valves performed perfectly under the negative pressure conditions.

Impressed by the stability of our product and our ability to understand their unique technical environment, the Korean client has since made JRVAL their exclusive supplier for valve components.

Need a valve solution for a tough environment?

Whether you are dealing with complex back-pressure issues or need standard industrial valves, JRVAL leverages integrated production capabilities to deliver the right solution.

Contact Our Engineering Team

JRVAL

JRVAL Jan 16 2026

Jan 16 2026