Renewable Energy Sector: A Guide to Selecting Butterfly Valves for Photovoltaic Power Plant Cooling Systems

As the demand for solar energy surges, the efficiency and reliability of photovoltaic (PV) power plants have become paramount. A critical, yet often overlooked, component is the plant's cooling system, which relies on precise flow control. This guide provides essential criteria for selecting the optimal industrial butterfly valve to ensure maximum performance and longevity in these demanding environments.

The Crucial Role of Valves in PV Cooling Systems

Cooling systems in PV plants circulate vast amounts of water or coolant to dissipate heat from panels and inverters, maintaining optimal operating temperatures. Effective flow control is essential for isolation during maintenance, system balancing, and emergency shutdowns. This is where the right valve selection becomes critical.

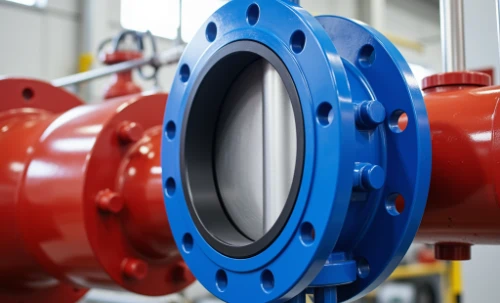

Butterfly valves are ideal for the large-diameter pipelines common in PV plant cooling loops.

Why a Butterfly Valve is the Preferred Choice

While various valve types exist, the butterfly valve consistently emerges as the top choice for PV cooling applications. In the classic debate of gate valve vs butterfly valve, the latter's compact, lightweight design reduces structural support requirements and costs, a significant factor in expansive solar fields. The simple quarter-turn mechanism of a lever operated butterfly valve allows for rapid actuation, which is far quicker than the multi-turn operation of gate valves.

- Efficiency and Cost-Effectiveness: The streamlined design requires less material, making it a more economical choice for the numerous valves needed across a plant, including the common 4 inch butterfly valve and 8 inch butterfly valve sizes.

- Space-Saving Design: Their minimal face-to-face dimension is invaluable in compact skid-mounted systems and crowded mechanical rooms.

- Suitability for Large Pipes: Butterfly valves are readily available in the large diameters (e.g., 12 inch butterfly valve, 16 butterfly valve, and larger) required for main cooling headers. A large diameter butterfly valve offers excellent flow characteristics with a low pressure drop.

- Versatile Operation: From a simple butterfly valve with handle to automated units like a pneumatic butterfly valve or one with a motorized actuator, they adapt to any control philosophy.

Critical Selection Criteria for Cooling System Valves

Selecting the right butterfly valve goes beyond size and pressure rating. Material science, sealing technology, and manufacturing precision are the pillars of long-term reliability.

1. Material Selection: The Foundation of Durability

The choice of material for the valve body and disc dictates its resistance to corrosion and its overall lifespan. As a butterfly valve factory with over 20 years of experience rooted in butterfly valve casting, JRVAL understands that material integrity is non-negotiable. Our founder, a renowned casting expert, ensures every valve's material composition meets or exceeds international standards, whether it's an ASME valve, DIN valve, or JIS butterfly valve.

- Ductile Iron & Carbon Steel (WCB): Excellent, cost-effective choices for standard water cooling loops. A wcb butterfly valve is a common specification for general industrial service.

- Stainless Steel (SS304, SS316, CF8M): Essential for systems using treated water with corrosion inhibitors or for enhanced longevity in harsh environments. A stainless steel butterfly valve, especially a butterfly valve ss316 or cf8m butterfly valve, provides superior corrosion resistance.

2. Sealing Performance: The Zero-Leakage Imperative

Preventing coolant loss is vital for both economic and environmental reasons. The heart of a valve's sealing capability is its seat. An epdm seat butterfly valve is the standard for water applications due to its excellent resilience and temperature range. For more aggressive media, a ptfe seat butterfly valve or teflon lined butterfly valve may be required.

Crucially, achieving bi-directional zero-leakage is a key performance indicator. While this is the hallmark of a high-cost triple offset butterfly valve, innovative manufacturers like JRVAL have engineered structural modifications in soft-seated valves. This allows our standard centerline valve and double eccentric butterfly valve models to deliver bubble-tight shutoff in both directions without the added cost, providing premium performance and value.

3. Installation Type: Wafer vs. Lug Butterfly Valve

The connection style impacts installation and maintenance. The debate of wafer vs lug type butterfly valve is a common one. A wafer type butterfly valve is sandwiched between two pipe flanges, offering a cost-effective and compact solution. However, the lug type butterfly valve, with threaded inserts, offers a significant maintenance advantage.

A key feature of a quality lug butterfly valve is the precision of its threaded holes. At JRVAL, we focus on high-precision valve machining, ensuring our lug type butterfly valve installation is smooth and straightforward, with easy bolt alignment. This design allows for the removal of downstream piping while the valve remains in place, a critical feature for end-of-line service.

Recommended JRVAL Valve Solutions for PV Cooling

JRVAL offers a comprehensive range of solutions engineered specifically for the challenges of renewable energy infrastructure. As a leading china butterfly valve manufacturer, we provide the right type butterfly valve for every application within your cooling system.

High-Performance Butterfly Valves (HPBV)

Our double offset butterfly valve design is perfect for main circulation lines and high-pressure applications. The eccentric disc action minimizes seat wear, ensuring a longer service life and sustained sealing performance.

Explore HPBV Models

Resilient Seated Lug & Wafer Valves

The workhorse for auxiliary lines, our concentric wafer butterfly valve and lug style butterfly valves offer unmatched value. They feature our innovative bi-directional zero-leakage seal and are available as a pn16 butterfly valve.

View Resilient Seated Valves

Multi-Standard & OEM Solutions

We specialize in providing valves for global projects. Whether you need an api 609 butterfly valve for a US project or a din butterfly valve for a European one, we can supply different standards in a single shipment.

Discuss Your ProjectThe JRVAL Advantage: Your Partner in Renewable Energy

For small and medium-sized enterprises driving the renewable energy revolution, partnering with the right supplier is crucial. JRVAL is not just a distributor; we are a source butterfly valve supplier with complete control over our process.

- Total Quality Control: From raw material sourcing and our in-house butterfly valve casting to precision CNC butterfly valve machining and final butterfly valve assembly, we oversee every step. This guarantees quality that third-party assemblers cannot match.

- Engineering Expertise: With 20 years of experience, we don't just sell valves; we engineer solutions. Our expertise in materials and structural design means you get a superior product, like our cost-effective bi-directional zero-leakage seal.

- Precision & Reliability: Our commitment to high-tolerance machining means easier installation and better performance, especially evident in our easy-to-install lug type butterfly valve models.

- Flexibility & Customization: As an OEM manufacturer, we thrive on complexity. We can produce a single batch of valves to multiple international standards (专标专供), simplifying procurement for global projects.

- Exceptional Value: By controlling the entire manufacturing process, we offer pricing that is highly competitive against major brands, delivering high-quality, reliable valves that fit the budgets of growing enterprises.

Choose JRVAL as your China butterfly valve supplier and gain a partner dedicated to the quality, performance, and success of your photovoltaic projects.

Need a Valve for Your PV Project?

Our experts are ready to help you find the perfect solution.

JRVAL

JRVAL Aug 04 2025

Aug 04 2025