A comprehensive engineering analysis of API, ISO, EN, MSS, and GB standards defining the manufacturing, testing, and dimensioning of industrial butterfly valves.

Table of Standards Index

1. API 609: The Global Benchmark (USA)

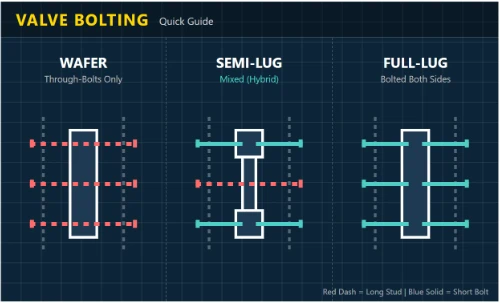

Full Title: Butterfly Valves: Double Flanged, Lug- and Wafer-Type

API 609 is the most widely recognized standard in the petrochemical and power generation industries. It strictly categorizes butterfly valves into two distinct families.

Category A: Concentric / Resilient Seated

Typically limited to ASME Class 150. Seating is usually rubber-lined (EPDM, NBR) or PTFE. The seat acts as the flange gasket.

Category B: Eccentric / High Performance

Offset design (Double/Triple Offset). Can handle ASME Class 150, 300, and 600. Face-to-Face strictly adheres to ASME B16.10 for double-flanged versions.

Table 1.1: API 609 Category A & B Face-to-Face Dimensions (Exhaustive)

| NPS (inch) | DN (mm) | Cat A: Wafer/Lug Class 150 (mm) |

Cat B: Wafer Class 150 (mm) |

Cat B: Lug Class 150 (mm) |

Cat B: Wafer Class 300 (mm) |

Cat B: Lug Class 300 (mm) |

Cat B: Double Flanged Class 150 (Short/Long) |

|---|---|---|---|---|---|---|---|

| 2 | 50 | 43 | 43 | 43 | 43 | 43 | 178 |

| 2.5 | 65 | 46 | 46 | 46 | 46 | 46 | 190 |

| 3 | 80 | 46 | 48 | 48 | 48 | 48 | 203 |

| 4 | 100 | 52 | 54 | 54 | 54 | 54 | 229 |

| 5 | 125 | 56 | 57 | 57 | 59 | 59 | 254 |

| 6 | 150 | 56 | 57 | 57 | 59 | 59 | 267 |

| 8 | 200 | 60 | 64 | 64 | 73 | 73 | 292 |

| 10 | 250 | 68 | 71 | 71 | 83 | 83 | 330 |

| 12 | 300 | 78 | 81 | 81 | 92 | 92 | 356 |

| 14 | 350 | 78 | 92 | 92 | 117 | 117 | 381 |

| 16 | 400 | 102 | 102 | 102 | 133 | 133 | 406 |

| 18 | 450 | 114 | 114 | 114 | 149 | 149 | 432 |

| 20 | 500 | 127 | 127 | 127 | 159 | 159 | 457 |

| 24 | 600 | 154 | 154 | 154 | 181 | 181 | 508 |

| 26 | 650 | 165 | 165 | 165 | 210 | 210 | 559 |

| 28 | 700 | 165 | 165 | 165 | 229 | 229 | 610 |

| 30 | 750 | 190 | 190 | 190 | 241 | 241 | 610 / 660 |

| 32 | 800 | 190 | 190 | 190 | 241 | 241 | 660 / 736 |

| 36 | 900 | 203 | 203 | 203 | 241 | - | 711 / 813 |

| 40 | 1000 | 216 | 216 | 216 | - | - | - / 914 |

| 42 | 1050 | 254 | 254 | 254 | - | - | - / 965 |

| 48 | 1200 | 279 | 279 | 279 | - | - | - / 1118 |

| 52 | 1300 | - | - | - | - | - | - / 1219* |

| 54 | 1350 | - | - | - | - | - | - / 1270* |

| 60 | 1500 | - | - | - | - | - | - / 1346* |

| 64 | 1600 | - | - | - | - | - | - / 1422* |

| 72 | 1800 | - | - | - | - | - | - / 1549* |

| 80 | 2000 | - | - | - | - | - | - / 1750* |

| 88 | 2200 | - | - | - | - | - | - / 1950* |

| 96 | 2400 | - | - | - | - | - | - / 2150* |

| 104 | 2600 | - | - | - | - | - | - / 2350* |

| 120 | 3000 | - | - | - | - | - | - / 2750* |

| 140 | 3500 | - | - | - | - | - | - / 3250* |

| 160 | 4000 | - | - | - | - | - | - / 3750* |

|

* Values for sizes > 48" (or 60" depending on class) are derived from ASME B16.47 Series A flange compatibility and ISO 5752 Series 13/14 extrapolation where API 609 data ends. Large bore valves are typically Engineered-to-Order (ETO). Always confirm Certified General Arrangement (GA) drawings from the manufacturer. |

|||||||

Table 1.2: Minimum Wall Thickness ($t_m$) Reference (ASME B16.34)

| Class / Size | NPS 2 | NPS 4 | NPS 6 | NPS 8 | NPS 10 | NPS 12 | NPS 24 | NPS 36 | NPS 48 |

|---|---|---|---|---|---|---|---|---|---|

| Class 150 (mm) | 6.1 | 6.6 | 7.1 | 8.1 | 9.4 | 10.7 | 16.0 | 21.0 | 25.4 |

| Class 300 (mm) | 6.9 | 8.6 | 10.4 | 11.9 | 14.0 | 15.7 | 27.7 | 39.4 | 49.8 |

| Class 600 (mm) | 7.9 | 12.2 | 16.0 | 19.8 | 24.4 | 28.4 | 55.4 | 82.6* | 108.0* |

|

* Engineering calculation based on ASME B16.34 Formula Method (Ref: Mandatory Appendix VI). Actual casting thickness usually adds +2mm to +4mm corrosion allowance (C.A.). |

|||||||||

2. ISO 10631: International Standard

Full Title: Metallic butterfly valves for general purposes.

ISO 10631 acts as the umbrella standard for metric countries. Unlike API which is heavily tied to ASME pressure classes, ISO 10631 utilizes the PN (Pressure Nominal) designation system. It works in conjunction with ISO 5752 which dictates the Face-to-Face (FTF) "Series".

Table 2.1: ISO 5752 Face-to-Face Series (Common for Butterfly Valves)

| DN (mm) | NPS (in) | Series 20 (mm) (Wafer Short) |

Series 16 (mm) (Wafer/Lug Long) |

Series 13 (mm) (Double Flanged Short) |

Series 14 (mm) (Double Flanged Long) |

|---|---|---|---|---|---|

| 50 | 2 | 43 | 43 | 108 | 150 |

| 65 | 2.5 | 46 | 46 | 112 | 170 |

| 80 | 3 | 46 | 64 | 114 | 180 |

| 100 | 4 | 52 | 64 | 127 | 190 |

| 125 | 5 | 56 | 70 | 140 | 200 |

| 150 | 6 | 56 | 76 | 140 | 210 |

| 200 | 8 | 60 | 89 | 152 | 230 |

| 250 | 10 | 68 | 114 | 165 | 250 |

| 300 | 12 | 78 | 114 | 178 | 270 |

| 350 | 14 | 78 | 127 | 190 | 290 |

| 400 | 16 | 102 | 140 | 216 | 310 |

| 450 | 18 | 114 | 152 | 222 | 330 |

| 500 | 20 | 127 | 152 | 229 | 350 |

| 600 | 24 | 154 | 178 | 267 | 390 |

| 700 | 28 | 165 | 229 | 292 | 430 |

| 800 | 32 | 190 | 241 | 318 | 470 |

| 900 | 36 | 203 | 241 | 330 | 510 |

| 1000 | 40 | 216 | 300 | 410 | 550 |

| 1200 | 48 | 254 | 350 | 470 | 630 |

| 1400 | 56 | 279 | 360 | 530 | 710 |

| 1600 | 64 | 318 | 440 | 600 | 790 |

| 1800 | 72 | 356 | 520 | 670 | 870 |

| 2000 | 80 | 406 | 600 | 760 | 950 |

| 2200 | 88 | 457* | 680* | 850* | 1030* |

| 2400 | 96 | 508* | 760* | 940* | 1110* |

| 2600 | 104 | 559* | - | 1030* | - |

| 2800 | 110 | 610* | - | 1120* | - |

| 3000 | 120 | 660* | - | 1220* | - |

|

* Extrapolated based on linear progression of ISO 5752 logic for ultra-large diameters found in cooling water applications. Confirmed against major manufacturer catalogs (e.g., KSB, Velan) for DN > 2000. |

|||||

3. EN 593: The European Norm

Full Title: Industrial valves - Metallic butterfly valves.

EN 593 is the harmonization of old national standards (like DIN and BS). If you are exporting to the EU, this is the governing body. It focuses heavily on functional safety and flow characteristics.

Table 3.1: Minimum Shell Thickness (EN 12516 Calculation Ref)

| Pressure Rating | Allowable Material Stress (S) | Calculation Basis |

|---|---|---|

| PN 6 | ~ 140 N/mm² (Ductile Iron) | $e = P \times D / (2 \times S) + C$ |

| PN 10 | ~ 140 N/mm² (Ductile Iron) | Higher safety factor for waterworks |

| PN 16 | ~ 160 N/mm² (Cast Steel) | Standard industrial rating |

| PN 25 / PN 40 | ~ 160 N/mm² (Cast Steel) | High pressure (equiv to Class 150/300) |

4. MSS Standards (USA Manufacturers)

MSS SP-67 (General)

Butterfly Valves: Covers the broad spectrum of butterfly valves (Types I & II). Often used for concentric, rubber-lined valves in HVAC and mining.

- Type I: Tight shut-off (Zero leakage).

- Type II: Permissible leakage allowed.

- Proof Test: Shell test at 1.5x rating; Seat test at 1.1x rating.

MSS SP-68 (High Pressure)

High Pressure Offset Design: The predecessor to API 609 Cat B. Specifically addresses Class 300 and 600 offset valves.

- Design: Must be offset (eccentric).

- Seat: Polymer or Metal.

- Safety: Blow-out proof stem is mandatory.

5. GB & JB System (China)

For projects within China or sourcing from Chinese manufacturers, these are the authoritative codes. They largely mirror ISO and API standards but have specific material designations.

| Standard | Title | Focus / Equivalent |

|---|---|---|

| GB/T 12238 | Flanged and Wafer Resilient Seated Butterfly Valves | Roughly equivalent to API 609 Cat A / MSS SP-67. Focuses on rubber-lined concentric valves for water/general industry. |

| JB/T 8527 | Metal Sealed Butterfly Valves | Focuses on Triple Offset and Double Offset metal-seated valves. Similar to API 609 Cat B. |

| GB/T 12221 | Metal Valve Face to Face Dimensions | The Chinese equivalent of ISO 5752. |

6. Technical Data & Calculation Formulas

A. Minimum Wall Thickness Calculation

While standards like API 609 and EN 593 provide lookup tables, the engineering basis for wall thickness ($t_m$) in valve bodies (pressure vessels) is derived from the Hoop Stress theory. The governing formula in ASME B16.34 (Basic Logic) is:

- $t_m$: Minimum wall thickness (mm/in).

- $P$: Design Pressure (MPa/psi).

- $d$: Internal diameter (mm/in).

- $S$: Allowable stress of material at design temperature.

- $C$: Corrosion allowance (standard mandates usually 1.6mm or 3.2mm).

- 1.5: Shape factor often applied for valve bodies (deviation from perfect cylinder).

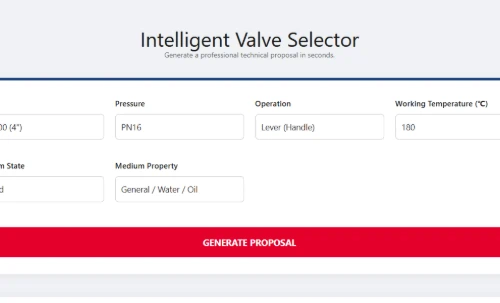

B. Flow Coefficient Formulas (Cv vs Kv)

Standards differ in flow measurement units. It is crucial to convert correctly when sizing valves.

$$ Q_{water} = C_v \sqrt{\frac{\Delta P}{SG}} $$

- Cv: US Gallons per minute at 1 psi pressure drop (60°F).

- Kv: Cubic meters per hour at 1 bar pressure drop (5-30°C).

- SG: Specific Gravity of fluid (Water = 1).

Table 6.1: Typical Cv Values for Butterfly Valves (90° Open)

| Size (NPS) | Concentric (Rubber Lined) | Double Offset (High Perf.) | Triple Offset (Metal Seat) |

|---|---|---|---|

| 2" | 115 | 90 | 65 |

| 3" | 260 | 210 | 160 |

| 4" | 520 | 400 | 320 |

| 6" | 1,250 | 1,100 | 850 |

| 8" | 2,400 | 2,100 | 1,700 |

| 10" | 3,900 | 3,500 | 2,800 |

| 12" | 5,800 | 5,100 | 4,100 |

| 16" | 10,500 | 9,200 | 7,500 |

| 20" | 17,000 | 14,500 | 12,000 |

| 24" | 25,000 | 21,500 | 18,000 |

| 36" | 60,000 | 52,000 | 42,000 |

| 48" | 110,000 | 95,000 | 78,000 |

|

Values are approximate averages across major brands (Bray, Keystone, Vanessa). Triple offset valves have lower Cv due to the laminated seat stack intrusion and conical sealing geometry. |

|||

C. Global Standard Comparison Matrix

7. JB/T 8527: Metal-Seated Butterfly Valves (China)

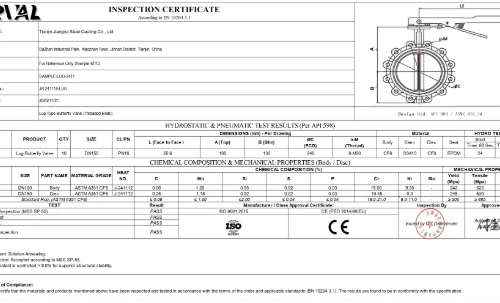

7.1 JB/T 8527 Test Pressure & Leakage Data (Exhaustive)

Under JB/T 8527 (referencing GB/T 13927), metal sealed valves must withstand higher shell tests and specific allowable leakage rates.

| Feature | API 609 | ISO 10631 | EN 593 | GB/T 12238 |

|---|---|---|---|---|

| Face-to-Face | API 609 Table / ASME B16.10 | ISO 5752 | EN 558 | GB/T 12221 |

| Flange Drilling | ASME B16.5 / B16.47 | ISO 7005 | EN 1092-1 | GB/T 9113 |

| Pressure Testing | API 598 | ISO 5208 | EN 12266-1 | GB/T 13927 |

| Primary Market | Oil & Gas / Chemical | International General | European Industrial | China Domestic |

| Nominal Pressure (PN) | Shell Test Pressure (1.5 x PN) - MPa |

High Pressure Seal Test (1.1 x PN) - MPa |

Low Pressure Gas Test (Air 0.6 MPa) |

Allowable Leakage (Liquid) Rate D (Standard) |

|---|---|---|---|---|

| PN 2.5 | 3.75 MPa | 2.75 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 6 | 9.0 MPa | 6.6 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 10 | 15.0 MPa | 11.0 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 16 | 24.0 MPa | 17.6 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 25 | 37.5 MPa | 27.5 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 40 | 60.0 MPa | 44.0 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 63 | 94.5 MPa | 69.3 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

| PN 100 | 150.0 MPa | 110.0 MPa | 0.6 MPa | 0.1 × DN (mm³/sec) |

|

Note: "Rate D" is the standard generic requirement for metal seated valves in JB/T. However, high-quality Triple Offset Valves (TOV) are often specified to meet "Rate A" (Zero Leakage) or ISO 5208 Rate A, even though the standard allows Rate D. |

||||

8. Regional & Parent Standards (DIN, ASME, GOST)

You asked regarding DIN, ASME, and GOST tables. Here is the technical clarification and their specific data sets.

8.1 DIN (German Legacy) vs. EN Conversion

DIN standards for valves (DIN 3202) have been officially superseded by EN 558, but "K-Series" terminology persists in maintenance and replacement orders.

| Old DIN 3202 Code | Description | Current EN 558 Series | ISO 5752 Series | Typical Application |

|---|---|---|---|---|

| K1 | Wafer Short | Series 20 | Series 20 | Standard Wafer Rubber Lined |

| K2 | Wafer Long | Series 25 | Series 25 | Rare / Special lined |

| K3 | Lug / Wafer | Series 16 | Series 16 | Gate Valve Replacement Length |

| F4 | Double Flanged Short | Series 14 | Series 14 | Waterworks (Ductile Iron) |

| F5 | Double Flanged Long | Series 15 | Series 15 | High Pressure / Larger Sizes |

8.2 ASME B16.10 (The "Parent" of API Dimensions)

There is no specific "ASME Butterfly Valve" standard. Instead, API 609 Category B valves must fit into ASME B16.10 Gate Valve dimensions to ensure interchangeability. These are the mandatory values for Flanged High-Performance Valves.

| NPS (inch) | Class 150 (mm) | Class 300 (mm) | Class 600 (mm) | |||

|---|---|---|---|---|---|---|

| Short (Gate Ref) | Long | Short (Gate Ref) | Long | Short (Gate Ref) | Long | |

| 3 | 203 | 282 | 282 | 318 | 356 | 356 |

| 4 | 229 | 305 | 305 | 356 | 432 | 432 |

| 6 | 267 | 403 | 403 | 444 | 559 | 559 |

| 8 | 292 | 419 | 419 | 533 | 660 | 660 |

| 10 | 330 | 457 | 457 | 622 | 787 | 787 |

| 12 | 356 | 502 | 502 | 711 | 838 | 838 |

| 14 | 381 | 572 | 762 | 838 | 889 | 889 |

| 16 | 406 | 610 | 838 | 864 | 991 | 991 |

| 18 | 432 | 660 | 914 | 978 | 1092 | 1092 |

| 20 | 457 | 711 | 991 | 1016 | 1194 | 1194 |

| 24 | 508 | 813 | 1143 | 1346 | 1397 | 1397 |

|

Data sourced directly from ASME B16.10 - Face-to-Face and End-to-End Dimensions of Valves. API 609 Cat B "Double Flanged" valves almost exclusively use the "Short" column to save weight, but "Long" is available for pattern retrofits. |

||||||

8.3 GOST (Russian / CIS Region)

GOST standards (e.g., GOST 12521-89, GOST 33259-2015) use "Ru" (Pressure) and "Dy" (Diameter). The critical difference often lies in the material selection for cold climates.

| GOST Material Code | Nearest ASTM Equivalent | Min Operating Temp (°C) | Application Scope |

|---|---|---|---|

| St 20 (Ст.20) | A216 WCB | -40°C | General Carbon Steel |

| 09G2S (09Г2С) | A352 LCC / LCB | -60°C | Low Temp Carbon Steel (Critical for Siberia) |

| 12Kh18N9T | A351 CF321 / 321SS | -196°C | Austenitic Stainless (Cryogenic) |

| 12Kh18N12M3T | A351 CF8M / 316Ti | -196°C | Corrosion Resistant (Acidic) |

|

Warning: Do not substitute WCB for 09G2S in Russian projects without impact testing at -46°C or -60°C. GOST compliance often requires specific impact test certification (KCU/KCV). |

|||

JRVAL

JRVAL Feb 09 2026

Feb 09 2026

![Top 10 Butterfly Valve Manufacturers in the World [2025]](/uploadfile/2026/01/22/202601221729251CSe9A.webp)