1.1 Introduction to the Valve Stem

1.1.1 Role and Criticality of the Stem in a Butterfly Valve Assembly

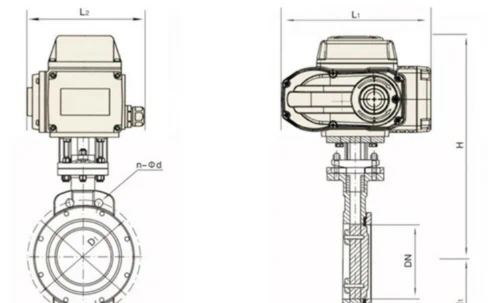

The valve stem, or shaft, is the critical component that connects the external actuator (e.g., a handle, gear operator, or pneumatic/electric actuator) to the internal disc. It is the sole conduit for transmitting the operational torque required to position the disc, thereby controlling the flow of fluid. Its integrity and proper design are paramount to the valve's reliability, safety, and performance. A stem failure results in a complete loss of valve control, potentially leading to catastrophic system failure.

1.1.2 Primary Functions: Torque Transmission, Disc Positioning, and Sealing

The stem serves three primary functions:

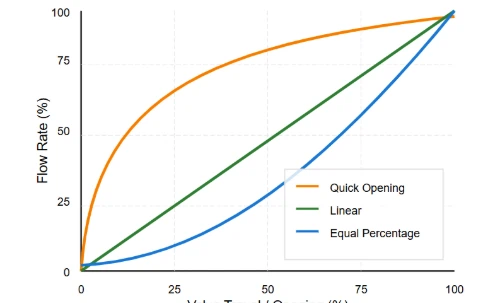

- Torque Transmission: It must withstand and transmit the torque generated by the actuator to overcome hydrodynamic forces, seat/unseat friction, and bearing friction to rotate the disc.

- Disc Positioning: It must hold the disc securely and accurately in any position from fully open to fully closed, ensuring precise flow modulation and tight shut-off.

- Sealing: The stem must pass from the "wet" process area inside the valve to the "dry" external environment without allowing process fluid to escape. This is accomplished through a stem sealing system, typically comprising packing rings and glands.

1.1.3 Overview of Stem Types (Rotary Motion)

For butterfly valves, which are quarter-turn (90°) rotary devices, stems are designed for rotational motion. The main architectural variations, such as one-piece (through stem) and two-piece (stub stem) designs, are determined by the valve's overall design, pressure class, and intended application. These will be explored in detail in Part 2.

1.2 Core Terminology and Concepts

1.2.1 Torque (Seating, Unseating, Hydrodynamic, Bearing, Packing)

Torque is the rotational force required to operate the valve. The total operational torque is a sum of several components:

- Seating Torque: The torque required to compress the valve seat and achieve a bubble-tight seal. This is often the highest torque value for resilient-seated valves.

- Unseating Torque: The torque required to break the disc away from the seat, overcoming static friction and seat adhesion.

- Hydrodynamic Torque: The torque generated by the fluid flow acting on the surface of the disc. It is typically highest at partially open positions (e.g., 60-80° open).

- Bearing Torque: The frictional torque from the stem bearings/bushings that support the stem.

- Packing Torque: The frictional torque from the stem sealing system (packing).

1.2.2 Stem Blowout and Anti-Blowout Design Features

Stem blowout is a critical failure mode where internal pressure ejects the stem from the valve body. This is a major safety hazard. Modern valve standards (e.g., API 609) mandate anti-blowout designs. This is typically achieved by incorporating a shoulder or collar on the stem that is larger than the stem bore in the valve body, or by using a retaining ring, ensuring the stem is retained by the body even if the actuator is removed under pressure.

1.2.3 Stem Packing, Sealing Mechanisms, and Fugitive Emissions

Stem packing is a system of deformable rings (e.g., PTFE, Graphite) compressed within a packing box to create a seal around the stem. This prevents process fluid from escaping along the stem, a phenomenon known as fugitive emissions. The design of the packing system is critical for environmental compliance and plant safety, especially in toxic or volatile services.

1.2.4 Galling and Anti-Galling Provisions

Galling is a form of severe adhesive wear that can occur between sliding metal surfaces under high contact pressure. It can cause the stem and bearings or stem and disc connection to seize. Prevention involves careful material selection (using materials with different hardnesses and compositions), providing high-quality surface finishes, and using appropriate lubrication or anti-galling coatings/treatments (e.g., nitriding).

1.2.5 Key, Spline, and other Drive Geometries

These are the mechanical interfaces used to transmit torque from the stem to the disc and from the actuator to the stem. Common geometries include square drives, Double 'D' drives, keyed shafts, and splined connections. The choice of geometry depends on the torque requirements, desired precision, and manufacturing cost.

JRVAL

JRVAL Aug 11 2025

Aug 11 2025