From News: HOME › NEWS › Butterfly Valve TCO

Part 1: Foundational Concepts of TCO

1.1 Defining Total Cost of Ownership

The Total Cost of Ownership (TCO) is a financial estimate intended to help buyers and owners determine the direct and indirect costs of a product or system. For an industrial component like a butterfly valve, TCO transcends the initial purchase price—often referred to as Capital Expenditure (CAPEX)—to encompass the entire spectrum of costs incurred throughout the asset's lifecycle. This includes all Operational Expenditures (OPEX) such as energy, maintenance, and repair, as well as eventual decommissioning and disposal costs. Viewing a valve through the TCO lens provides a holistic understanding of its true financial impact, revealing that the cheapest valve to procure is rarely the cheapest valve to own.

1.2 The TCO Imperative in Modern Industry

In today's competitive and highly regulated industrial landscape, a rigorous TCO analysis is no longer optional; it is a fundamental requirement for achieving long-term strategic goals. Its importance is multifaceted:

- Profitability: Minimizing lifecycle costs directly enhances operational margins and overall profitability.

- Reliability & Uptime: A TCO-driven selection process favors robust, high-quality valves, which significantly reduces the frequency of unplanned downtime, a major source of financial loss.

- Sustainability & Compliance: TCO analysis incorporates factors like energy consumption and fugitive emissions, aligning asset management with corporate sustainability goals and environmental regulations.

- Risk Mitigation: By considering factors like Mean Time Between Failures (MTBF) and the cost of catastrophic failure, TCO helps in mitigating operational, safety, and environmental risks.

While models can vary in complexity, the fundamental TCO formula for a physical asset like a butterfly valve is universally expressed as:

TCO = I + O + M + D

- [I] - Initial Acquisition & Installation Costs

- This component represents the total upfront capital expenditure (CAPEX) required to bring the valve from specification to a fully operational state within the process line. It includes far more than just the price on the invoice.

- [O] - Operational Costs

- These are the ongoing, recurring costs (OPEX) associated with the valve's day-to-day function over its entire service life. These costs are often less visible but can accumulate to exceed the initial investment significantly.

- [M] - Maintenance, Repair, & Overhaul (MRO) Costs

- This category includes all costs related to keeping the valve in a reliable operating condition, covering both planned preventive actions and unplanned corrective interventions. This component is heavily influenced by the cost of production downtime.

- [D] - Decommissioning & Disposal Costs

- These are the end-of-life costs incurred when the valve is removed from service. While often overlooked during procurement, they can be substantial, particularly in applications involving hazardous materials.

1.4 Scope and Purpose of This Archive

This digital archive is engineered to serve as an exhaustive reference for the precise calculation, comparison, and strategic minimization of butterfly valve TCO. It provides the granular data necessary to move beyond simplistic price-based decisions towards value-based procurement. Users should leverage this resource for:

- Developing detailed and accurate valve specifications.

- Conducting objective, data-driven comparisons between different valve types, materials, and manufacturers.

- Justifying investments in higher-quality, more reliable valves by demonstrating their superior long-term financial performance.

Part 2: The TCO Equation Deconstructed - Exhaustive Cost Factors

2.0 [I] - Initial Acquisition & Installation Costs (CAPEX)

The initial investment is the most visible component of TCO but is often underestimated. A comprehensive accounting of CAPEX must include the following sub-categories:

2.1 Valve Purchase Price Breakdown

- Base Valve Cost: The fundamental price of the valve, which varies significantly based on design type (e.g., Concentric/Resilient-Seated, High-Performance Double Offset, Triple Offset).

- Material Surcharges: Additional costs for specific materials of construction for the body, disc, stem, and seat, driven by market prices for alloys (e.g., stainless steel, duplex, nickel alloys) and high-performance polymers.

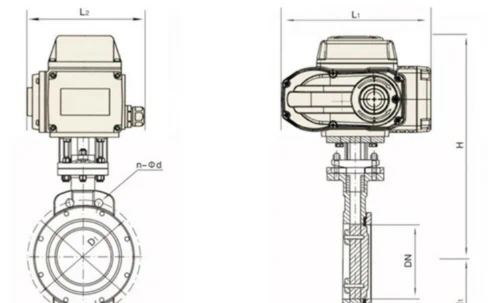

- Actuation & Control System Costs: The cost of the selected actuator (Manual lever/gearbox, Pneumatic, Electric, Hydraulic, Electro-hydraulic) and associated control components.

- Accessories Costs: The price of all required ancillary equipment, such as solenoid valves, limit switch boxes, intelligent positioners, air filter regulators, and volume boosters.

2.2 "Soft" Acquisition Costs

- Engineering & Specification Costs: The man-hours and resources dedicated to process analysis, valve sizing, material selection, and creation of technical specification sheets.

- Procurement & Administrative Costs: The internal costs of the purchasing process, including supplier vetting, request for quotation (RFQ) management, bid evaluation, and contract negotiation.

- Factory Acceptance Testing (FAT) & Certification Costs: Fees for specialized testing or witnessing required by the end-user (e.g., cryogenic testing, high-temperature testing) and for obtaining mandatory certifications (e.g., SIL, ATEX, Fire-Safe, PED).

2.3 Logistics & Transportation Costs

- Freight & Shipping: Costs for transporting the valve from the manufacturer's facility to the job site, including any expedited shipping premiums.

- Insurance: Cost of insuring the asset during transit.

- Special Handling & Storage: Costs associated with crating, heavy-lift requirements, and proper on-site or off-site warehousing to prevent damage or degradation before installation.

2.4 Installation & Commissioning Costs

- Labor Costs: The wages for the multi-disciplinary team required for installation, including pipefitters, welders, mechanics, electricians, and instrumentation & control (I&C) technicians.

- Equipment Rental: The cost of renting necessary equipment such as cranes, lifting gear, welding machines, and calibration tools.

- System Integration & Programming: Costs associated with connecting the valve's control package to the plant's Distributed Control System (DCS) or Programmable Logic Controller (PLC), including programming, loop checks, and function testing.

- Initial Operator Training: The cost of training plant personnel on the proper operation and basic maintenance of the new valve assembly.

- Cost of Production Downtime during Installation: A critical and often substantial cost representing the value of lost production while the process line is shut down for the installation work.

3.0 [O] - Operational Costs (OPEX)

Operational costs represent the ongoing expenditures required to run the butterfly valve as part of the larger process. While individually small, these costs accumulate over a service life of years or decades, often dwarfing the initial CAPEX. A thorough TCO analysis must meticulously account for them.

3.1 Energy Consumption Costs

Energy is one of the most significant and frequently overlooked operational costs. It manifests in two primary forms:

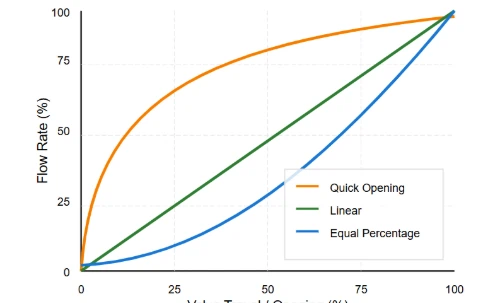

- Pumping Costs due to Pressure Drop (ΔP): Every valve introduces a restriction in the line, causing a permanent pressure loss that the system's pumps must overcome. This requires energy. A valve with a higher flow coefficient (Cv/Kv) for a given opening angle creates less pressure drop and thus consumes less energy over its lifetime. This cost is calculated based on pump efficiency, electricity cost, and operational hours. (Note: This section will be linked to detailed Cv/Kv data tables in Appendix B).

- Actuator Energy Consumption: The power required to operate the valve's actuator.

- Pneumatic Actuators: Consume compressed air, which is a costly utility to produce (requiring compressors, dryers, and filters). Leaks in air lines or the actuator itself further exacerbate this cost.

- Electric Actuators: Consume electricity, both during stroking (motor operation) and often in standby mode to power internal electronics and anti-condensation heaters.

- Hydraulic Actuators: Consume energy via a hydraulic power unit (HPU) and require periodic fluid replacement and filtering.

3.2 Consumables & Utilities

Beyond direct energy for actuation, other operational consumables contribute to TCO:

- Compressed Air / Nitrogen Quality: The cost of drying, filtering, and sometimes lubricating the instrument air used for pneumatic actuators and positioners. Poor air quality can lead to premature failure of seals and internal components.

- Hydraulic Fluid & Filters: The recurring cost of replacing hydraulic fluid and filters in hydraulic power units according to a preventive maintenance schedule.

3.3 Monitoring & Supervision Costs

- Routine Operator Inspection Labor: The cost of man-hours for operators performing routine walk-downs to visually inspect the valve for leaks, damage, or abnormal operation.

- Process Control System (PCS) Costs: Costs associated with maintaining the integrity of the valve's control loop, including periodic calibration of sensors and positioners to ensure it accurately responds to the control signal.

3.4 Insurance & Regulatory Compliance Costs

- Fugitive Emissions Monitoring & Reporting: For services regulated by environmental agencies (e.g., EPA), this includes the cost of mandatory Leak Detection and Repair (LDAR) programs. This involves specialized equipment (e.g., TVA 2020) and trained personnel to "sniff" the valve stem packing and body seals for leaks, as specified by standards like EPA Method 21. Valves with certified low-emission (Low-E) packing (e.g., to ISO 15848-1 or API 624) significantly reduce these monitoring and potential fine-related costs.

- Safety Integrity Level (SIL) Verification Costs: For valves designated as part of a Safety Instrumented Function (SIF), there are recurring costs for periodic proof testing to verify that the valve assembly (valve, actuator, solenoid) meets its required Probability of Failure on Demand (PFD) target.

4.0 [M] - Maintenance, Repair, & Overhaul (MRO) Costs

MRO costs are a critical component of TCO and are heavily influenced by the initial choice of valve quality, type, and materials. These costs are a combination of planned, predictable expenses and unplanned, often catastrophic, expenses.

4.1 Planned / Preventive Maintenance (PM)

- Scheduled Inspection & Testing: The cost of labor and equipment for performing routine diagnostic tests during planned outages, such as seat leakage tests (per API 598 or EN 12266-1), stroking time tests, and torque profiling.

- Scheduled Component Replacement ("Soft Goods"): The cost of predefined "soft kits" (including seats, seals, O-rings, and gaskets) and the labor to install them at fixed intervals to prevent age- or cycle-based failures.

- Lubrication: Cost of lubricants and labor for periodically lubricating gearbox internals, actuator moving parts, and stem threads.

4.2 Unplanned / Corrective Maintenance (CM)

- Troubleshooting & Diagnostics Labor: The high-urgency man-hours required from engineers and technicians to identify the root cause of an unexpected valve failure.

- Cost of Replacement Components: The price of spare parts needed for the repair. This is often inflated due to emergency procurement premiums and expedited shipping costs.

- Equipment & Labor for Repair: Includes costs for in-line repair if possible, or the more substantial cost of removing the valve from the line, transporting it to a workshop, and reinstalling it after repair.

4.3 The Critical Cost of Downtime

This is arguably the most significant, yet most difficult to quantify, cost in the MRO category. It must be calculated for both planned and unplanned maintenance events.

- Lost Production Revenue: The direct financial loss calculated by multiplying the plant's production rate (e.g., barrels per day, tons per hour) by the market value of the product and the duration of the shutdown. For a critical valve, this can amount to millions of dollars per day.

- Consequential Costs: The cascading impact of a single valve failure on interconnected upstream and downstream processes, potentially causing wider plant disruption, product spoilage, or failure to meet contractual supply obligations.

- Potential for Safety Incidents or Environmental Fines: A valve failure can lead to safety hazards (e.g., release of toxic or flammable media) or environmental spills, resulting in enormous regulatory fines, cleanup costs, and reputational damage.

4.4 Spare Parts Inventory Costs

- Cost of Capital (Holding Costs): The capital tied up in spare parts (complete valves, actuators, soft kits, etc.) sitting in a warehouse, which could otherwise be invested elsewhere.

- Warehouse & Inventory Management Costs: The physical cost of warehouse space, climate control, and the labor required to manage, track, and preserve the inventory.

- Spoilage & Obsolescence Costs: The risk that spare parts, especially elastomeric seals with a limited shelf life, will degrade and become unusable over time, or that they will become obsolete as the plant technology is updated.

5.0 [D] - Decommissioning & Disposal Costs

The final phase in the valve's lifecycle, end-of-life costs are planned expenditures that must be factored into the initial TCO calculation for a complete picture.

5.1 Removal & De-installation Labor Costs

The man-hours and equipment (e.g., cranes, cutting tools) required to safely isolate, de-energize, and remove the valve assembly from the pipeline during a planned shutdown.

5.2 Transportation to Disposal/Recycling Facility

The logistics cost of moving the decommissioned valve from the plant site to a certified disposal or recycling center.

5.3 Disposal Costs

The final financial transaction at the end of the valve's life. This can be a net cost or a credit.

- Scrap Value (Credit): A potential positive cash flow from selling the valve's metal components (especially high-value alloys like stainless steel, Duplex, or Monel) to a scrap metal recycler.

- Hazardous Material Handling Costs (Cost): If the valve was used in a toxic, radioactive, or otherwise hazardous service, there will be significant costs associated with specialized decontamination, handling, and disposal procedures to comply with environmental and safety regulations.

- Landfill/Disposal Fees (Cost): For non-recyclable materials (e.g., some plastics, elastomers) or contaminated components, there will be fees for their legal disposal in a certified landfill.

5.4 Site Remediation Costs

In cases where a valve has caused long-term contamination of the surrounding soil or area due to chronic leakage, there may be additional costs for environmental cleanup and site remediation after its removal.

Part 3: Critical Influencing Factors & Comparative Analysis

The Total Cost of Ownership is not a static number; it is a dynamic outcome determined by a series of critical engineering and procurement decisions made at the project's outset. This section provides a comparative analysis of the primary factors that influence a butterfly valve's lifecycle cost.

6.0 Impact of Valve Design & Type on TCO

The fundamental design of the butterfly valve is the most significant driver of its performance, application range, and ultimately, its TCO.

- 6.1 Concentric (Resilient-Seated) vs. High-Performance (Double & Triple Offset)

- Concentric (Resilient-Seated):

- TCO Profile: Lower CAPEX, higher OPEX/MRO in demanding applications.

- Analysis: The disc seal is made of an elastomer or polymer that is interference-fit against the valve body. This design is simple and cost-effective initially. However, the friction during operation leads to seat wear, limiting its lifespan, especially in high-cycle or throttling applications. They are best suited for clean, lower-pressure, and lower-temperature utility services. Using them outside their intended service range leads to frequent seat replacement, high maintenance costs, and significant downtime.

High-Performance (Double/Triple Offset):

- TCO Profile: Higher CAPEX, significantly lower OPEX/MRO in demanding applications.

- Analysis: The "offset" geometry (double offset for soft/RTFE seats, triple offset for metal/laminated seats) ensures the disc cams into the seat without rubbing or friction. This dramatically reduces wear, extends service life, and provides superior sealing performance (especially bubble-tight shutoff in triple offsets). The higher initial cost is often quickly recuperated through reduced maintenance, longer intervals between shutdowns, and enhanced process reliability in critical, high-pressure, high-temperature, or high-cycle services.

- 6.2 Lug vs. Wafer vs. Double Flanged Body Designs

- Wafer Style:

- TCO Profile: Lowest CAPEX, higher MRO risk.

- Analysis: Held in place by compression between two pipe flanges using long bolts. They are the cheapest and lightest option. However, the entire line must be depressurized and drained to replace the valve, increasing maintenance downtime. Misalignment during installation is common, which can cause premature failure.

Lug Style:

- TCO Profile: Moderate CAPEX, lower MRO cost.

- Analysis: Features threaded lugs that allow the valve to be bolted directly to one pipe flange, enabling it to be used in dead-end service and allowing downstream piping to be removed while the valve remains in place under pressure. This significantly reduces maintenance time and complexity, lowering MRO costs despite a slightly higher initial price.

Double Flanged Style:

- TCO Profile: Highest CAPEX, highest installation security.

- Analysis: Has two separate flanges that bolt independently to each pipe flange. This is the most robust and secure connection, eliminating alignment issues. While the heaviest and most expensive, it is preferred in high-pressure, large-diameter, or critical applications where connection integrity is paramount, reducing the risk of costly leaks or failures.

- 6.3 Lined vs. Unlined Valves

- Lined Valves (e.g., PFA/PTFE Lined):

- TCO Profile: High CAPEX, potentially lowest TCO in highly corrosive services.

- Analysis: The valve's wetted surfaces are protected by a chemically inert liner. This allows a less expensive body material (e.g., Ductile Iron) to be used in place of exotic alloys (e.g., Hastelloy®, Titanium) for highly corrosive media. The TCO is favorable only if the liner integrity is maintained. A liner breach leads to catastrophic failure and full valve replacement.

Unlined (Alloy) Valves:

- TCO Profile: CAPEX varies from low (Carbon Steel) to very high (Exotic Alloys), TCO depends on matching the alloy to the service.

- Analysis: The valve material itself resists the process media. The TCO is optimized by selecting the most cost-effective alloy that provides the required service life without failure. Over-specifying an alloy leads to excessive CAPEX, while under-specifying leads to rapid corrosion, failure, and exorbitant MRO and downtime costs.

7.0 Impact of Materials of Construction on TCO

Material selection is a classic TCO trade-off between initial cost and lifecycle durability.

7.1 Body/Disc Materials

The choice impacts corrosion resistance, erosion resistance, strength, and lifespan.

- Cast/Ductile Iron: Low initial cost. Suitable for general utility services like water and air. Prone to rapid failure in corrosive or chemical applications, leading to very high MRO and risk costs.

- Carbon Steel (WCB): The industry baseline for oil & gas and general process applications. Offers good strength and temperature resistance at a moderate cost. Requires protective coatings in corrosive environments.

- Stainless Steels (e.g., CF8M/316): Higher initial cost than carbon steel but offers excellent corrosion resistance in a wide range of process fluids, significantly reducing maintenance and extending life, thus lowering TCO.

- Duplex/Super Duplex Stainless Steels: High initial cost. Offer superior strength and outstanding resistance to chloride stress corrosion cracking (e.g., in seawater applications). Drastically reduces TCO in these specific, aggressive environments by avoiding frequent replacement of standard stainless steel valves.

- Exotic Alloys (e.g., Monel, Hastelloy®, Inconel, Titanium): Very high CAPEX. Reserved for the most severe, highly corrosive, or high-temperature services where other materials would fail in weeks or months. Their use is justified by preventing near-constant failures and massive production losses, making their TCO lower than the "cheaper" alternatives in these niche applications.

7.2 Seat Materials

The seat is often the primary wear component, and its material directly dictates maintenance intervals.

- Elastomers (EPDM, NBR, Viton®): Low cost. Limited temperature and chemical resistance. Suitable for utility services. Frequent replacement is expected, so labor and downtime costs for MRO are a key part of their TCO.

- Plastics (PTFE, RTFE): Moderate cost. Excellent chemical resistance but susceptible to cold flow/deformation. Reinforced PTFE (RTFE) offers better stability and higher pressure/temperature ratings, justifying its higher cost with a longer life.

- Metal-to-Metal (e.g., in Triple Offset Valves): High initial cost. Integral to the valve body/disc or as a laminated seal ring (e.g., SS316/Graphite). Offers the highest temperature and pressure capabilities and is resistant to abrasion. Provides the lowest MRO cost and longest life in severe services, justifying the high CAPEX.

8.0 Impact of International & Regional Standards on TCO

Compliance with recognized standards is not a mere formality; it is a direct investment in quality, safety, and interchangeability, all of which have profound TCO implications.

- Design Standards (e.g., API 609, EN 593, MSS SP-67/68, AWWA C504): Adherence to a robust design standard like API 609 Category B (for high-performance valves) dictates specific minimum requirements for shaft strength, body thickness, and bearing design. This increases CAPEX but drastically improves reliability and service life, lowering MRO and downtime costs.

- Pressure-Temperature Rating Standards (e.g., ASME B16.34, EN 1092-1): These standards define the safe operating envelope of the valve. A valve compliant with ASME B16.34 has undergone rigorous engineering analysis and provides a verified, reliable pressure rating, reducing the risk of catastrophic failure due to body rupture, a cost that is effectively infinite.

- Testing & Inspection Standards (e.g., API 598, EN 12266-1/2): These standards mandate specific testing procedures and acceptance criteria for shell (hydrostatic) and seat leakage. A valve tested to a more stringent standard (e.g., zero-leakage) provides higher assurance of performance out-of-the-box, reducing costly "infant mortality" failures and immediate replacement needs.

- Material Standards (e.g., ASTM, EN, JIS, GB/T): These ensure that the materials used in the valve meet specific chemical composition and mechanical property requirements. Full traceability (e.g., via MTRs to EN 10204 3.1) guarantees that you are getting the alloy you paid for, preventing premature corrosion failures that would result from using a cheaper, non-compliant substitute.

- Fugitive Emission Standards (e.g., ISO 15848-1, API 624): Valves certified to these standards have packing systems designed and proven to minimize leakage of harmful or valuable process media. The higher CAPEX for a certified Low-E valve is offset by lower compliance costs (reduced LDAR monitoring), reduced product loss, and avoidance of environmental fines.

- Face-to-Face Dimension Standards (e.g., API 609, ISO 5752, EN 558): Compliance ensures that a new valve from any compliant manufacturer will have the same end-to-end dimension as the old one. This makes replacement simple and fast ("drop-in replacement"), minimizing costly piping modifications and reducing installation downtime and labor costs.

9.0 Impact of Application & Service Conditions on TCO

The TCO of a valve is ultimately realized within its specific application. A mismatch between the valve and the service conditions is the single fastest way to incur massive, unplanned costs.

- Media Type: The fluid or gas passing through the valve.

- Clean Service (e.g., Water, Air): Allows for simpler, lower-cost valve designs (e.g., concentric).

- Slurry / Abrasive Service: Requires hardened trim materials, full-bore designs, or specialized liners to resist erosion. Using a standard valve here results in rapid failure and extremely high MRO costs.

- Corrosive Service: Mandates careful selection of alloys or liners. The cost of failure (leakage of hazardous chemicals) is immense, justifying high CAPEX for the correct materials.

- High Purity Service: Requires special cleaning, surface finishes, and materials to prevent contamination, adding to CAPEX but being essential for product quality (e.g., in pharmaceutical or semiconductor manufacturing).

- Operational Parameters:

- Pressure & Temperature: These fundamentally dictate the required pressure class and material selection. Exceeding a valve's P-T rating is a direct path to catastrophic failure.

- Throttling vs. On/Off: Throttling (flow control) service is much more demanding than simple on/off (isolation) service. It can cause vibration, cavitation, and rapid wear. A high-performance valve designed for throttling will have a far lower TCO in such an application than a cheaper isolation valve that is misapplied.

- Cycle Frequency: A valve in a high-cycle application will experience accelerated wear of its dynamic seals (seat, packing). A valve designed for high cycles (e.g., with robust bearings and low-friction seals) will have a much lower TCO than a standard valve that requires frequent rebuilds.

- Installation Environment:

- Marine/Offshore: Requires special external coatings (e.g., to ISO 12944 C5-M) and often high-alloy materials (e.g., Duplex) to combat external corrosion, adding to CAPEX but preventing premature external failure.

- Explosive Atmosphere (ATEX/IECEx): Mandates certified electrical components (solenoids, switches) and anti-static features to prevent ignition sources, adding significant cost but being non-negotiable for safety.

Part 4: Advanced TCO Modeling & Strategic Implementation

Once all potential costs are identified, the next step is to structure them into a coherent model for analysis and strategic decision-making. This involves moving beyond simple arithmetic to incorporate financial principles and risk assessment, transforming TCO from a list of expenses into a powerful strategic tool.

10.0 Life Cycle Costing (LCC) Models for Butterfly Valves

Life Cycle Costing (LCC) is the formal methodology for conducting a TCO analysis. It provides a framework to compare valves with different cost profiles (e.g., low CAPEX/high OPEX vs. high CAPEX/low OPEX) on an equal footing.

10.1 Net Present Value (NPV) Analysis

The core principle of LCC is the time value of money: a dollar today is worth more than a dollar in the future. NPV analysis operationalizes this principle by discounting all future costs (OPEX, MRO) back to their present-day value. This allows for a true "apples-to-apples" comparison of the total cost of different valve options over their entire lifecycle.

- How it Works: The analysis requires estimating all costs for each year of the valve's expected service life. Each future year's cost is then reduced by a "discount rate" (which represents the cost of capital or inflation) to find its present value. The sum of all these discounted future costs, plus the initial investment (CAPEX), equals the TCO in today's money.

- TCO Implication: A valve with a lower NPV is the superior financial choice, even if its initial purchase price is higher. This model mathematically proves the value of investing in reliability and efficiency.

10.2 Sensitivity Analysis: Identifying the Most Critical Cost Drivers

A TCO calculation is based on assumptions (e.g., future energy costs, maintenance intervals, service life). Sensitivity analysis is a "what-if" technique that tests how the final TCO result changes when these key assumptions are varied. For example:

- "What is the impact on TCO if the cost of electricity increases by 30%?" (This highlights the value of energy-efficient, low-torque valves).

- "What if the actual maintenance interval for the 'cheaper' valve is 12 months instead of the planned 18?" (This quantifies the real cost of lower reliability).

- "How does the TCO change if the plant operates 24/7 versus 16/5?" (This emphasizes the amplified cost of downtime).

By identifying the variables with the most significant impact on the TCO, decision-makers can focus their analysis and supplier negotiations on the factors that truly matter.

11.0 The Role of Predictive Maintenance (PdM) & IIoT in Reducing TCO

Modern technology offers powerful ways to shift from costly reactive or scheduled maintenance to a more intelligent, cost-effective predictive model. The Industrial Internet of Things (IIoT) is at the forefront of this transformation.

- The Shift from PM to PdM: Instead of replacing parts on a fixed schedule (Preventive Maintenance), Predictive Maintenance uses real-time data to predict when a component is likely to fail, allowing maintenance to be performed only when necessary.

- Enabling Technologies: Smart valve positioners, acoustic sensors, vibration monitors, and integrated temperature sensors can continuously track a valve's health. They can detect:

- Increased torque demand (indicating seat wear, scaling, or lubrication failure).

- Acoustic signatures of internal leakage.

- Changes in stroking time.

- Abnormal vibration.

- TCO Reduction: This data-driven approach dramatically reduces TCO by minimizing unplanned downtime, eliminating unnecessary maintenance tasks and material costs, preventing catastrophic failures, and extending the overall useful life of the asset. The investment in IIoT-enabled valves (higher CAPEX) is often justified by massive MRO and downtime cost savings.

12.0 Qualitative & Intangible Factors in TCO Analysis

Not all factors can be easily entered into a spreadsheet, but they have real, tangible impacts on TCO. A comprehensive analysis must consider these qualitative elements.

12.1 Supplier Reliability & Technical Support

A low-cost valve from a supplier with poor support can become extremely expensive during a problem. Key considerations include: quality of documentation, responsiveness of technical support, availability and lead time of spare parts, and willingness to assist in troubleshooting. A reliable supplier is a form of insurance that lowers long-term risk and MRO costs.

12.2 Manufacturer Reputation & Track Record

A manufacturer's reputation, built over years of service, serves as a valuable proxy for reliability. Choosing a valve from a manufacturer with a proven track record of success in similar applications provides a higher degree of confidence and reduces the risk of premature failure, directly lowering the probable TCO.

12.3 Safety & Environmental Risk Mitigation

This is the ultimate intangible. While one can estimate the cost of a fine or cleanup, the full cost of a major safety incident (injury or loss of life) or significant reputational damage is immeasurable. Investing in a valve with superior safety features (e.g., certified fire-safe design, SIL-rated components, proven fugitive emissions performance) is a strategic decision to minimize these high-consequence risks. In this context, the higher CAPEX is a small premium to pay for lowering the "Risk" component of the TCO to its absolute minimum.

13.0 Case Studies

The following simplified case studies illustrate how TCO principles apply in real-world scenarios.

13.1 Case Study 1: TCO Comparison - Triple Offset (TOV) vs. Resilient Seated in High-Cycle Steam Service

- Application: Isolation valve in a saturated steam line, cycling 10 times per day.

- Option A (Low CAPEX): Resilient-seated butterfly valve with EPDM seat. Initial Cost: \$2,000.

- Option B (High CAPEX): Triple Offset butterfly valve with metal-to-metal seating. Initial Cost: \$9,000.

- TCO Analysis:

- The EPDM seat in Option A degrades rapidly in steam service, requiring replacement every 6 months. Cost per intervention: \$500 in parts + 8 hours of downtime (at \$10,000/hr) + labor = \$81,000. Annual MRO cost is \$162,000.

- The TOV in Option B is designed for this service and operates maintenance-free for a projected 5+ years.

- Conclusion: Despite being 4.5x more expensive initially, the TOV's TCO becomes dramatically lower than the resilient-seated valve's within the first maintenance cycle. The low-CAPEX option is the far more expensive choice.

13.2 Case Study 2: TCO Impact of a Cheaper, Non-Compliant Valve in a Corrosive Application

- Application: Critical blocking valve in a pipeline carrying wet chlorine. Specification calls for a valve made from a certified (ASTM) high-nickel alloy.

- Option A (Compliant): Valve from a reputable manufacturer, made of the specified alloy with full material traceability (MTRs). Initial Cost: \$25,000.

- Option B (Non-Compliant): Valve from an unknown supplier, claimed to be "equivalent" material but without MTRs. Initial Cost: \$15,000.

- TCO Analysis:

- The procurement team selects Option B to save \$10,000 in CAPEX.

- Within 3 months, the valve's body develops pinhole leaks and fails catastrophically. The material was an inferior alloy with low corrosion resistance.

- The failure causes a 48-hour unplanned shutdown (\$1.2M in lost production), a hazardous material leak requiring emergency response and environmental cleanup (\$250,000), and regulatory fines (\$100,000). The total cost of this single failure is over \$1.5M, plus the cost of an emergency replacement with the correct valve.

- Conclusion: The \$10,000 "saving" in CAPEX resulted in a TCO that was orders of magnitude higher. This demonstrates that compliance with material standards is a non-negotiable factor in managing TCO and operational risk.

Part 5: Data Hub & Appendices

This section serves as the data-rich core of the archive, providing reference tables, calculation worksheets, glossaries, and lists of standards to support practical TCO analysis.

Appendix A: TCO Calculation Worksheet

The following table provides a structured worksheet to guide the TCO calculation process. Users can populate the fields for different valve options to compare their projected lifecycle costs. All future costs should be discounted to their Net Present Value (NPV) for an accurate comparison.

| TCO Calculation Worksheet |

| Cost Component |

Description / Sub-Item |

Estimated Cost ($) |

| Purchase Price |

Base Valve, Actuator, Accessories |

[Input] |

| "Soft" Costs |

Engineering, Procurement, FAT |

[Input] |

| Logistics |

Freight, Insurance, Handling |

[Input] |

| Installation |

Labor, Equipment, Commissioning |

[Input] |

| Downtime |

Cost of Production Loss during Install |

[Input] |

| Energy |

Pumping Costs (from ΔP) + Actuator Energy |

[Input] |

| Compliance |

LDAR Monitoring, SIL Proof Testing |

[Input] |

| Preventive Maint. |

Scheduled Kits, Labor, Lubrication |

[Input] |

| Corrective Maint. |

(Risk-Weighted) Unplanned Repairs |

[Input] |

| Downtime |

(Risk-Weighted) Production Loss from Failure |

[Input] |

| Inventory |

Holding Cost of Spare Parts |

[Input] |

| Removal |

Labor & Equipment |

[Input] |

| Disposal/Recycle |

Fees minus Scrap Value |

[Input] |

| TOTAL COST OF OWNERSHIP (NPV) |

[Calculated Sum] |

Appendix B: Reference Data Tables

B.1: Typical Flow Coefficients (Cv) by Valve Size and Type

| Valve Size (NPS / DN) |

Concentric / Resilient Seated |

High-Performance Double Offset |

| 30° Open |

60° Open |

90° Open |

30° Open |

60° Open |

90° Open |

| 3" / DN80 |

55 |

250 |

420 |

45 |

280 |

510 |

| 6" / DN150 |

230 |

1,050 |

1,750 |

200 |

1,200 |

2,100 |

| 12" / DN300 |

980 |

4,400 |

7,500 |

900 |

5,100 |

8,800 |

| 24" / DN600 |

4,200 |

19,000 |

32,000 |

3,900 |

22,000 |

38,000 |

| 36" / DN900 |

9,800 |

44,000 |

75,000 |

9,100 |

50,000 |

85,000 |

| 48" / DN1200 |

18,000 |

80,000 |

135,000 |

16,500 |

92,000 |

155,000 |

B.2: Typical Break Torque (Unseating) Requirements (in Nm)

| Valve Size (NPS / DN) |

ASME Class 150 / PN20 (at full ΔP) |

ASME Class 300 / PN50 (at full ΔP) |

| 3" / DN80 |

150 |

250 |

| 6" / DN150 |

500 |

900 |

| 12" / DN300 |

2,100 |

4,000 |

| 24" / DN600 |

12,000 |

25,000 |

B.3: Relative Material Cost Index

| Material |

Typical ASTM Grade |

Relative Cost Factor (RCF) |

| Carbon Steel |

WCB |

1.0 |

| Stainless Steel 316 |

CF8M |

~2.5 - 3.5 |

| Duplex Stainless Steel |

CD3MN (4A) |

~5 - 7 |

| Super Duplex SS |

CE3MN (5A) |

~8 - 10 |

| Nickel Aluminum Bronze |

C95800 |

~10 - 15 |

| Monel |

M35-1 |

~15 - 20 |

| Hastelloy® C276 |

CW2M |

~25 - 35 |

| Titanium |

Ti Gr. C-2 |

~30 - 40+ |

B.4: Standard Maintenance Schedules & Recommended Spare Parts

This provides a baseline for planning maintenance activities. Intervals must be adjusted based on service severity.

- Preventive Maintenance Schedule (Baseline):

- 6 Months: Visual inspection for leaks, external corrosion. Verify actuator function.

- 1 Year (Severe Service) / 2-3 Years (General Service): Perform partial-stroke test. Check/lubricate gearbox.

- 3-5 Years (or as needed): Replace "soft goods" (seat, packing, seals). Perform full breakout torque and seat leakage test.

- Recommended Spare Parts Inventory:

- Critical Spares (Hold On-Site): 1x complete spare valve assembly for most critical applications. "Soft Goods" repair kits for all valve types.

- General Spares (Supplier Stock): Bearings, stems, discs, gearboxes.

Appendix C: Glossary of Terms

- TCO (Total Cost of Ownership)

- The complete lifecycle cost of an asset, including initial purchase, operation, maintenance, and disposal.

- CAPEX (Capital Expenditure)

- The initial, upfront investment to acquire and install an asset.

- OPEX (Operational Expenditure)

- The ongoing, recurring costs of using an asset, such as energy and monitoring.

- MRO (Maintenance, Repair, and Overhaul)

- Costs associated with keeping an asset in reliable working condition, including downtime.

- Cv / Kv

- Flow coefficient; a relative measure of valve efficiency. A higher Cv/Kv value means less pressure drop and higher flow capacity for a given valve size.

- API 609

- An American Petroleum Institute standard governing the design, materials, and testing of butterfly valves.

- Triple Offset Valve (TOV)

- An advanced butterfly valve design with three offsets to eliminate friction, providing zero-leakage performance and long life in severe services.

- SIL (Safety Integrity Level)

- A measure of the reliability of a safety function, defined in the IEC 61508/61511 standards.

- Fugitive Emissions

- Unintentional leaks of process gases or vapors from sealed components like valve stem packing.

- LDAR (Leak Detection and Repair)

- A program to find and repair unintended fugitive emission leaks, often mandated by environmental regulations.

Appendix D: List of Referenced Standards & Norms

- Design: API 609, EN 593, MSS SP-67, MSS SP-68, AWWA C504

- Pressure-Temperature Ratings: ASME B16.34, EN 1092-1

- Face-to-Face Dimensions: API 609, ISO 5752, EN 558

- Testing & Inspection: API 598, EN 12266-1/2

- Fugitive Emissions: ISO 15848-1, API 624, EPA Method 21

- Material Specifications: ASTM International, EN (European Norms), JIS (Japanese Industrial Standards), GB/T (Chinese National Standards)

- Safety: IEC 61508, IEC 61511 (for SIL)

- Coating/Painting: ISO 12944

Appendix E: Bibliography & Further Reading

- American Petroleum Institute (API). (2016). API Standard 609: Butterfly Valves: Double-Flanged, Lug- and Wafer-Type. 8th Edition.

- European Committee for Standardization (CEN). (2015). EN 593: Industrial valves - Metallic butterfly valves.

- International Organization for Standardization (ISO). (2015). ISO 15848-1: Industrial valves — Measurement, test and qualification procedures for fugitive emissions — Part 1: Classification system and qualification procedures for type testing of valves.

- Bloch, H. P., & budgetary, P. (2011). Pump Wisdom: A Practical Guide to Pump Selection. John Wiley & Sons. (Contains valuable insights into system hydraulics and energy costs related to valves).

- Parisher, R. A., & Rhea, R. A. (2012). Pipe Drafting and Design. 3rd Edition. Elsevier. (Provides context on piping standards and integration).

JRVAL

JRVAL Aug 08 2025

Aug 08 2025