ZERO-FAILURE OEM INTEGRATION: THE LUG BUTTERFLY VALVE ENGINEERED FOR MARINE DUTY

For a leading Turkish shipbuilder and their OEM partners, a `lug valve` is a precision interface. As a top `china butterfly valve supplier`, we provide the engineering discipline required for flawless automation integration and a 30-year lifecycle in harsh marine environments.

Read The Full Case StudyTHE OEM'S INTEGRATION NIGHTMARE

Before partnering with us, the client's mechanical integration team faced constant, costly setbacks from their previous `industrial butterfly valve` suppliers, impacting project timelines and budgets.

Inconsistent Actuator Fit

Stem drives varied from batch to batch, failing `ISO 5211` standards. This caused sloppy actuator connections, backlash, and sheared stems, halting piping installations and causing significant rework costs.

Premature Component Failure

An inferior `A216 WCB butterfly valve` body, lacking proper heat treatment, was susceptible to brittle fracture from engine room vibration, posing a significant long-term reliability risk for the entire vessel.

Rapid Corrosion Failure

The standard paint on the `carbon steel butterfly valve` body failed from salt spray even before sea trials, a massive quality issue that tarnished the final product's perceived value and required costly on-site repairs.

Our Engineered Solution

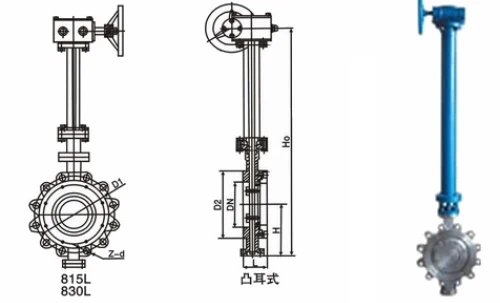

A `LUG TYPE BUTTERFLY VALVE` BUILT FOR PREDICTABILITY

We delivered an `asme butterfly valve` under our ISO 9001 system: the A216 `WCB butterfly valve`, a Bare-Stem `Lug Butterfly Valve` designed for seamless OEM integration and lifetime endurance. This is why we are leading `manufacturers of butterfly valves`.

Mitigating Fatigue Risk

Every `wcb body butterfly valve` undergoes **normalizing heat treatment** at 910°C. This refines the grain structure, dramatically increasing fatigue resistance and impact toughness to withstand decades of vibration, a non-negotiable for `marine butterfly valve` applications.

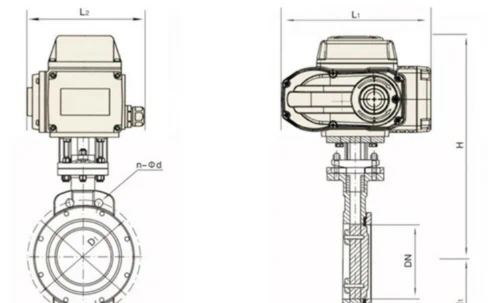

Eliminating Integration Bottlenecks

The valve stem head is CNC-machined to strictly comply with **ISO 5211**, holding a **dimensional tolerance of ±0.1mm**. This guarantees a perfect, zero-backlash fit, reliable torque, and eliminates the primary failure point, saving critical assembly time.

Ensuring Asset Integrity

Our `epoxy coated butterfly valves` feature a **three-coat system for C4 (High Salinity) environments**. This includes a zinc-rich primer, epoxy mid-coat, and polyurethane topcoat, guaranteeing external integrity and a quality finish for years.

"They don't just supply a `butterfly valve`; they provide a precise foundation for our automation process. Their control over heat treatment and machining tolerances ensures the longevity our vessels require."

— Head of Mechanical Integration, A Leading Turkish Shipbuilder

VERIFIED MANUFACTURING & PRODUCT CERTIFICATION

Our commitment to quality is proven by our state-of-the-art `valve machining` capabilities and validated by internationally recognized product certifications, giving you complete purchasing confidence.

PRECISION CNC MACHINING CENTERS

CNC Machining Center 1

CNC Machining Center 2

CNC Machining Center 3

CNC Machining Center 4

CNC Machining Center 5

CNC Machining Center 6

CNC Machining Center 7

CNC Machining Center 8

CNC Machining Center 9

CNC Machining Center 10

CNC Machining Center 11

API 609

ISO 9001

CE Marking

BV

DNV Product

EXPLORE RELATED VALVE SOLUTIONS

Our engineering expertise extends across a wide range of `industrial butterfly valve` types designed for specific operational challenges. We are a `china butterfly valve manufacturer` for every need.

DE-RISK YOUR SUPPLY CHAIN

Valve failure shouldn't be your bottleneck. Partner with an engineering-focused `butterfly valve factory` to specify a solution that delivers quantifiable performance, on-time delivery, and long-term asset integrity.

JRVAL

JRVAL Aug 11 2025

Aug 11 2025