Butterfly Valve vs. Ball Valve: The Ultimate Technical Guide

Beyond simple definitions, this definitive guide provides an in-depth engineering comparison. We cover everything from flow performance (Cv) and materials to maintenance and TCO, empowering you to make a truly informed decision.

Guide Navigation

The Core Concept: A Professional Overview

Butterfly Valve

Quick Analogy: A damper in a ventilation duct. A simple, rotating disc controls the passage.

An economical, lightweight quarter-turn valve for on/off or throttling services. Its primary advantage is its compact design and low cost in large pipe diameters.

Key Principle: Flow control via a rotating disc.

Ball Valve

Quick Analogy: The mechanism inside a garden hose nozzle. A bored-out sphere aligns with or blocks the pipe.

A robust quarter-turn valve providing superior, zero-leak shutoff. It excels in high-pressure applications and where an unobstructed flow path is critical.

Key Principle: Flow control via a rotating, ported ball.

Working Principle: A Visual Comparison

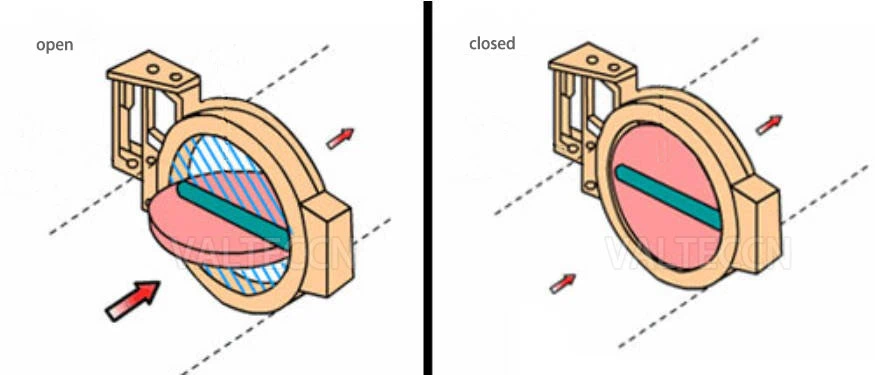

Butterfly Valve Operation

The disc rotates 90 degrees to move from fully closed to fully open.

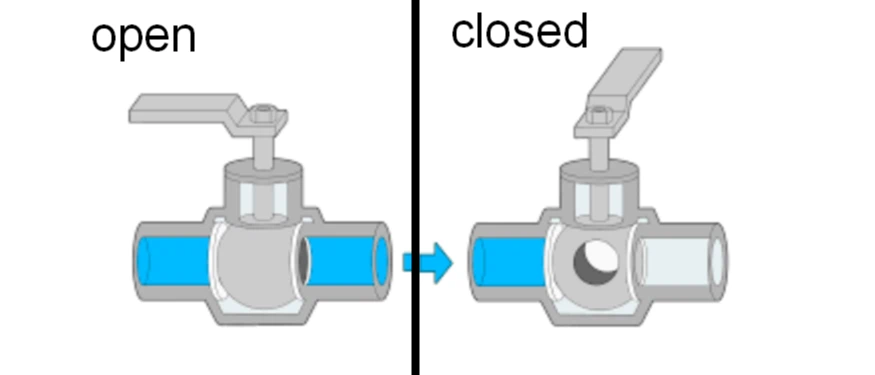

Ball Valve Operation

The ball rotates 90 degrees to move from fully closed to fully open.

Anatomy & Construction

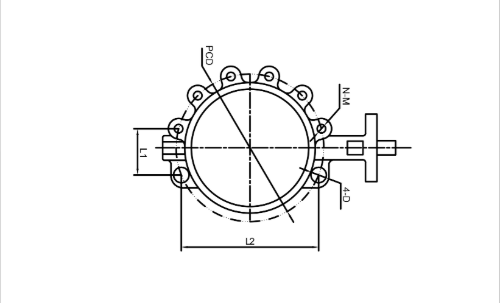

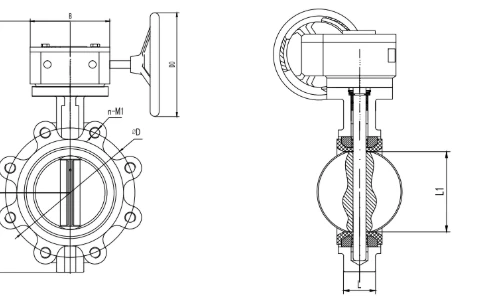

Butterfly Valve (Lug-Style)

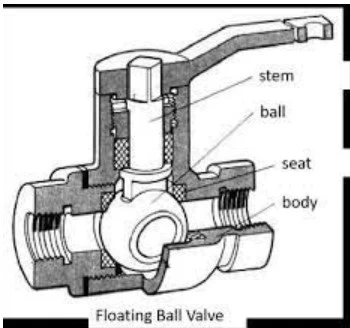

Ball Valve (Floating)

The Valve Families Explained

To make a correct choice, you must first understand the fundamental design differences within each valve family.

Butterfly Valve Types

Concentric (Resilient Seated)

The simplest design where the stem is centered in the disc, and the disc is centered in the pipe. Sealing relies on the disc compressing into a soft, flexible liner.

Best for: General purpose, low-pressure water, air, and where cost is a primary driver.

Double Eccentric (High-Performance)

Features two offsets: 1) The stem is behind the disc, and 2) The stem is slightly to one side. This lifts the disc off the seat as it opens, reducing friction and wear.

Best for: Higher pressures, throttling, and frequent cycling. The standard for reliable, zero-leakage performance.

Triple Eccentric (Triple-Offset)

Adds a third offset in the geometry of the seating surface, creating a conical sealing profile. This design completely eliminates friction during operation, allowing for metal-to-metal sealing.

Best for: Severe service, cryogenics, high temperatures, and critical high-pressure applications.

Ball Valve Types

Floating Ball

The ball is not mechanically fixed and is free to "float" slightly. Upstream pressure pushes the ball into the downstream seat to create a seal.

Best for: Smaller sizes and general to medium-pressure applications. Cost-effective and highly reliable.

Trunnion Mounted Ball

The ball is supported by a top and bottom stem (the trunnion), holding it in a fixed position. The seats are spring-loaded and move toward the ball to seal.

Best for: Large diameters and high-pressure service. This design significantly reduces operating torque and seat wear.

The Definitive Decision Matrix

Here is the detailed, data-driven comparison you need. We break down every critical performance factor to declare a winner for each specific engineering requirement.

Sealing & Shutoff

The ability to provide a "bubble-tight" (zero-leakage) seal when closed.

Butterfly Valve

High-performance and triple-offset designs achieve true zero-leakage per API 598. Concentric types may have minor leakage over time. ( But JRVAL concentric butterfly valve can realize bi-directonal zero leakage)

Ball Valve

Inherently excellent sealing due to the large seat contact area. The industry benchmark for critical shutoff, especially trunnion designs.

Throttling & Control

The suitability for regulating flow at intermediate positions (not just fully open/closed).

Butterfly Valve

Excellent. Provides a repeatable, semi-linear flow characteristic ideal for process control. Offset designs are exceptionally stable for throttling.

Ball Valve

Poor. Standard ball valves are for on/off only. Throttling creates high velocity which erodes the seats. Requires expensive V-port designs for control.

Size & Weight

The physical footprint and mass of the valve, impacting installation and support.

Butterfly Valve

Extremely compact and lightweight, especially in wafer/lug styles. This advantage grows exponentially with pipe size (DN200+).

Ball Valve

Significantly heavier and bulkier due to its body construction. Requires more substantial pipe supports and lifting equipment for installation.

Maintenance & Reparability

Ease and cost of servicing the valve to extend its operational life.

Butterfly Valve

Excellent. The primary wear part, the seat/liner, is often easily and inexpensively replaceable in the field without special tools.

Ball Valve

Poor. Field repair is complex. Usually requires removing the valve from the line and sending it to a workshop, or complete replacement.

Cost (Initial & TCO)

Initial purchase price versus Total Cost of Ownership over the valve's life.

Butterfly Valve

Lower initial cost, especially in large sizes. Significantly lower TCO due to cheaper installation, smaller actuators, and low-cost repairs.

Ball Valve

Higher initial cost and higher TCO due to weight, difficult repairs, and larger, more expensive actuation requirements.

Pressure & Temperature

The valve's ability to operate reliably under high system pressures and temperatures.

Butterfly Valve

Triple-offset designs can handle very high pressures (ASME Class 1500) and temperatures (up to 815°C) with metal seats.

Ball Valve

Trunnion designs are the champions of extreme high-pressure service (API 10000+). Temperature is limited by its soft seat materials.

Flow Path & Pressure Drop

The effect the valve has on system pressure and its suitability for "pigging".

Butterfly Valve

The disc is always in the flow path, creating a pressure drop and turbulence. It cannot be "pigged" (pipeline cleaning).

Ball Valve

A full-bore ball valve offers a completely straight, unobstructed path, resulting in minimal pressure drop. It is fully piggable.

Handling of Slurries & Solids

Ability to operate with fluids containing suspended solids or abrasive particles.

Butterfly Valve

Poor. Abrasive particles get trapped between the disc and the seat, causing rapid wear and failure. Not recommended for slurries.

Ball Valve

Good. The straight flow path and wiping action of the ball against the seats help clear particles. Metal-seated designs are excellent for abrasive service.

Industry Application Showdown: The Clear Winner for Your Sector

Theory is good, but practical application is everything. Here’s a breakdown of 12 common industrial scenarios and the definitive winner for each.

Water & Wastewater

For large-diameter pipelines, the butterfly valve's significant cost, weight, and space savings are unbeatable. Its excellent throttling is ideal for flow control in treatment processes.

Oil & Gas Pipeline

The trunnion-mounted ball valve provides a bubble-tight seal for preventing fugitive emissions, handles extreme pressures, and its full bore allows for "pigging" (pipeline inspection).

HVAC & Buildings

The lightweight, compact, and low-torque nature of high-performance butterfly valves makes them the go-to for balancing chilled/hot water lines. Their cost-effectiveness is key.

Chemical Processing

For bulk chemicals, a lined Butterfly Valve offers superb corrosion resistance at lower cost. For high-purity or critical shutoff, a specialty alloy Ball Valve is superior.

Food & Beverage

A sanitary, cavity-filled ball valve offers a smooth, pocket-free internal profile that prevents bacteria growth and is easily cleaned (CIP/SIP). Standard butterfly valves have crevices.

Mining & Slurries

A ceramic-lined or metal-seated ball valve offers superior resistance to the extreme abrasion of slurries. A butterfly valve's disc and soft seat would be quickly destroyed in this service.

Pulp & Paper

A high-performance or offset design excels at controlling fibrous stock. They are less prone to clogging than ball valves and offer better throttling for process consistency.

Power Generation

Triple-offset butterfly valves (TOVs) are the standard for high-temp steam and boiler feedwater. Their metal-to-metal, zero-friction seating is ideal for thermal cycling.

Fire Protection

A grooved-end butterfly valve with a supervisory switch is the standard for fire sprinkler systems. They are UL/FM approved, fast-acting, and have a clear visual open/closed indicator.

Pharmaceuticals

A cavity-filled, electro-polished stainless steel ball valve is the winner. It ensures no media gets trapped, meeting strict hygiene standards for aseptic applications.

Bulk Solids & Powders

The clear, unobstructed path of a full-bore ball valve is essential for handling powders, pellets, and grains without clogging. A butterfly valve's disc would impede flow.

Marine & Shipbuilding

Lug-style, high-performance butterfly valves are dominant. Their extreme space and weight savings are critical on a ship. Ni-Al-Bronze material is key for seawater corrosion resistance.

Engineering Selection Criteria: Beyond the Basics

A valve is only as good as its materials and compliance. Here are the non-negotiable factors for professional selection.

1. Material Selection (Body, Disc, Seat)

The choice of material is dictated by the fluid's temperature, pressure, and corrosiveness.

- Seat Material is Critical:

- EPDM: Excellent for water, glycols. (Standard for HVAC)

- BUNA-N (NBR): Ideal for oils, fuels, and petroleum products.

- Viton® (FKM): Superior resistance to chemicals and high temps.

- PTFE: Handles highly corrosive media and wide temp range.

- Metal Seat: For abrasives, high temperatures (>250°C), or fire-safe needs.

2. Industry Standards & Certifications

Compliance is a guarantee of performance and safety. Look for:

- API 609: Primary standard for butterfly valves.

- API 6D: Standard for pipeline ball valves.

- API 598: Universal standard for valve testing and leakage rates.

- ISO 5211: Standard for actuator mounting flanges.

- Fire Safe (API 607): Critical for flammable media.

3. Actuation & Automation

How the valve is operated impacts cost and system integration.

- Manual: Lever (small sizes) or Gearbox (large sizes).

- Pneumatic Actuator: Fast-acting, reliable, common in process control.

- Electric Actuator: Precise positioning, ideal for remote control.

Key Insight: Butterfly valves generally have lower torque requirements, allowing for smaller, less expensive actuators.

Frequently Asked Technical Questions (FAQ)

Q: Which valve has a higher Cv (Flow Coefficient)?

A: A full-bore ball valve has a higher Cv than a butterfly valve of the same size because it offers a completely unobstructed flow path. The butterfly valve's disc is always present in the flow, creating a slight pressure drop and thus a lower Cv. This is a critical calculation for system designers.

Q: Are butterfly valves bi-directional?

A: It depends. Concentric butterfly valves are typically bi-directional. However, high-performance (double/triple offset) valves often have a preferred flow direction for optimal sealing. This is always specified on the valve body or in the technical datasheet.

Q: What is "Total Cost of Ownership" (TCO) in this comparison?

A: TCO is more important than initial price. For a large-diameter valve, a butterfly valve's TCO is often significantly lower. TCO = Initial Price + Installation Cost (lower weight) + Actuation Cost (lower torque) + Maintenance Cost (field-replaceable seats). A ball valve's higher weight and difficult repairs can lead to a higher TCO over its lifespan.

Move Beyond the Myth. Engineer the Right Solution.

Your process deserves more than a default choice. As this guide demonstrates, modern butterfly valve technology offers superior performance in a vast range of applications. Our engineers are ready to help you analyze your specific service conditions and select the optimal valve to maximize performance and minimize your total cost of ownership.

Need Help with Valve Selection?

We provide engineered solutions tailored to your process.

JRVAL

JRVAL Aug 02 2025

Aug 02 2025