Double Flanged vs. Lug Style Butterfly Valve

The definitive engineering breakdown. Move beyond simple definitions and understand the critical trade-offs in performance, cost, and reliability that determine project success.

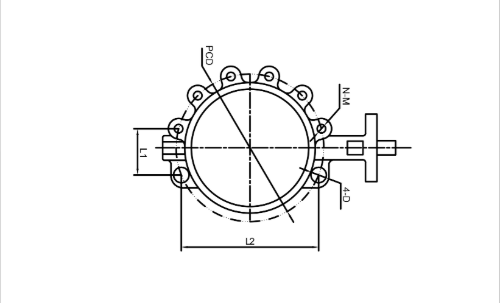

Double Flanged

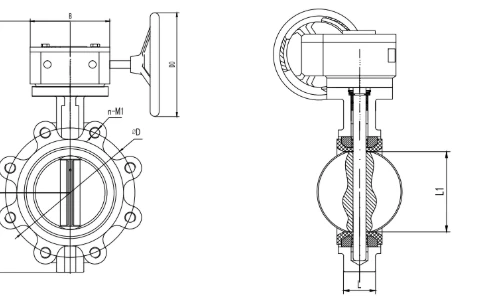

Lug Style

The Choice That Defines Your System's Integrity

Choosing between a double flanged and a lug-style butterfly valve seems straightforward, but it's a decision with profound consequences for your system's total cost of ownership, maintenance schedule, and operational safety. Both valves regulate flow, but their mechanical connection to the piping system dictates their ideal applications and inherent risks.

This guide is for engineers, project managers, and procurement specialists who need to make a data-driven decision, not just a selection based on habit or initial price.

We will dissect their designs, compare their performance under pressure, and reveal which valve truly triumphs in specific industrial scenarios.

Key Differences at a Glance

A fundamental overview of the pros and cons inherent to each design.

Double Flanged Butterfly Valve

- Maximum Strength: Two integral flanges provide unmatched structural rigidity.

- High-Pressure Standard: The default choice for high-pressure (ASME 600+) and large-diameter applications.

- Lower Installation Risk: Over-tightening damages a replaceable bolt/nut, not the valve body.

- Heavier & Bulkier: Significantly increases structural support needs and shipping costs.

- Higher Initial Cost: More material and complex casting lead to a higher price point.

Lug Style Butterfly Valve

- Lightweight & Compact: Lower weight and cost, ideal for space-constrained systems.

- Dead-End Service Champion: Allows downstream pipe removal for maintenance while holding pressure.

- Easier Installation: Can be aligned and held in place with just a few bolts, simplifying the process.

- Installation Risk: Stripping the threaded lugs by over-tightening can ruin the entire valve.

- Pressure Limitations: Generally not preferred for extremely high-pressure or high-vibration systems.

The Definitive Decision Matrix

This detailed, data-driven comparison breaks down every critical performance factor to declare a winner for each specific engineering requirement.

Dead-End Service

Ability to isolate pressure from one side when the other is disconnected.

Lug Style

Excellent. Designed specifically for this, bolts secure it to one flange.

Double Flanged

Excellent. Also designed for this with ultimate structural integrity.

Cost, Weight & Size

Initial purchase price, physical weight, and face-to-face dimensions.

Lug Style

Lower cost, significantly lighter, more compact. Easier to handle and store.

Double Flanged

Higher cost, substantially heavier, and bulkier due to integral flanges.

High-Pressure & Pipe Stress

Ability to handle high pressures and absorb stress from pipe misalignment.

Lug Style

Very strong, but integrity relies on threaded lugs. Can be a stress point.

Double Flanged

The standard for very high pressures (ASME 600+) and demanding services.

Installation & Alignment

Effort required to position and install the valve, affecting labor time and safety.

Lug Style

Easier. Can be positioned with a few bolts, simplifying second flange alignment.

Double Flanged

More difficult due to heavy weight. Requires careful support and alignment.

Maintenance & Repairability

Ease of servicing the valve or adjacent equipment without a full system shutdown.

Lug Style

Superior. Allows removal of downstream piping while the valve stays in place, holding pressure.

Double Flanged

Also excellent for dead-end, but valve removal itself is more labor-intensive.

Installation Risk (TCO)

Potential for damage during installation and its impact on Total Cost of Ownership.

Lug Style

Higher risk. Overtightening can strip body threads, causing total valve loss and project delays.

Double Flanged

Lower risk. Overtightening may break a standard bolt/nut, which is a cheap, easy fix.

Bolt & Gasket Management

Complexity and cost associated with fasteners and sealing elements.

Lug Style

Fewer bolts (cap screws), but they are specialized. Requires two gaskets.

Double Flanged

Twice as many bolts and nuts, but they are standard/cheaper. Requires two gaskets.

Vibration & System Rigidity

Performance in systems with heavy vibration, such as near large pumps or compressors.

Lug Style

Good, but the single-point bolt connections can be more susceptible to loosening over time.

Double Flanged

Superior. The sheer mass and dual, through-bolted connections create an extremely rigid unit.

Interchangeability

Ease of replacing other valve types (like gate or globe valves) with a butterfly valve.

Lug Style

Can be difficult as its face-to-face dimension is typically much shorter.

Double Flanged

Excellent. Often designed to ISO 5752 / ASME B16.10 for "drop-in" replacement.

Why JRVAL? Verifiable Capability, Not Just Claims.

As a source manufacturer, we offer unmatched control over every stage of production. This is our promise of quality, backed by transparent processes you can see.

Source Manufacturer Control

We dictate the exact metallurgical composition in our foundry and oversee every step of heat treatment (e.g., solution annealing, tempering) to ensure superior material properties.

Precision CNC Machining

Our advanced CNC centers guarantee tight tolerances on critical areas like the valve seat and stem packing, ensuring bubble-tight sealing and extended service life.

Guaranteed Zero-Leakage

We don't just meet the standard, we master it. Our soft-seated valves are engineered and individually tested to achieve API 598 bi-directional zero leakage as a baseline requirement.

Unmatched Standard Compatibility

Your project needs DIN flanges, JIS face-to-face, and ASME bodies? No problem. Our flexible production allows us to manufacture valves that are fully compliant with multiple international standards.

OUR 11 PRECISION CNC MACHINING CENTERS

CNC Center 1

CNC Center 2

CNC Center 3

CNC Center 4

CNC Center 5

CNC Center 6

CNC Center 7

CNC Center 8

CNC Center 9

CNC Center 10

CNC Center 11

Industry Application Showdown

Where the theory meets the ground. Here’s the definitive choice for common industrial scenarios.

Large Diameter Water Mains

For pipes over DN600 (24"), the structural rigidity and standardized face-to-face of Double Flanged valves make them the industry standard for municipal water transport.

Marine & Shipbuilding

Weight and space are paramount. Lug valves provide essential dead-end service for engine room maintenance without the excessive bulk of a double flanged model.

High-Pressure Steam Service

In power generation, the superior structural integrity of the Double Flanged body provides the highest safety level against thermal expansion and system stress.

HVAC & General Pump Isolation

For isolating pumps and chillers in commercial buildings, the Lug valve is perfect. It offers critical maintenance isolation at a fraction of the cost and weight.

Oil & Gas Terminals

In critical hydrocarbon service, safety is non-negotiable. The robust, low-risk installation and high-rigidity of Double Flanged valves make them the default choice.

Chemical Batch Processing

Systems requiring frequent line flushing, inspection, or reconfiguration benefit from the Lug style's ease of maintenance, reducing downtime between batches.

Desalination (RO) Plants

High-pressure reverse osmosis requires extreme durability. Double Flanged valves, often in Duplex or Super Duplex alloys, are essential to handle the pressure and corrosive brine.

Modular & Skid Systems

For prefabricated, modular process skids, the lightweight and compact nature of Lug valves is a significant advantage, reducing both structural requirements and shipping weight.

Mining & Slurry Transport

Abrasive slurries demand extreme toughness. The thick, solid body of a Double Flanged valve (often with abrasion-resistant liners) provides superior erosion resistance and longevity.

JRVAL In Action: The Critical Choice

How a data-driven decision secured a desalination plant's high-pressure system.

THE CHALLENGE: Uncompromising Reliability for RO Plant

A new Reverse Osmosis (RO) desalination plant in the Middle East required isolation valves for its high-pressure feed lines. The key requirements were: handling 65 bar (940 PSI) operating pressure, withstanding highly corrosive brine, and ensuring absolute system integrity with zero leakage.

THE ANALYSIS: Lug vs. Double Flanged Under Scrutiny

The project's EPC (Engineering, Procurement, and Construction) contractor considered both options. Here's a summary of their internal analysis:

Lug Style Proposal

- Cost: Lower initial valve cost.

- Installation: Lighter weight simplifies handling.

- Risk: High potential for lug thread stripping under the required bolt torque for 65 bar, leading to valve failure.

- Stress: Concentrates pipe stress on the valve body's threaded lugs, a major concern in high-vibration pump areas.

Double Flanged Proposal

- Strength: Superior structural integrity to handle pressure and pipe stress.

- Safety: Installation failure (broken bolt) is low-cost and easily fixed.

- Rigidity: Creates a solid, rigid unit with the piping, ideal for high-pressure, high-flow systems.

- Cost: Higher initial valve cost and weight.

THE VERDICT & JRVAL'S SOLUTION

DECISION: Double Flanged for Long-Term Security

The EPC chose the Double Flanged design, prioritizing long-term reliability and risk mitigation over short-term cost savings. They selected JRVAL for our ability to provide a custom, high-performance solution.

Our Contribution: We manufactured DN400 Double Flanged Butterfly Valves with a Duplex Stainless Steel (ASTM A890 4A) body for corrosion resistance. Each valve underwent a specific solution annealing heat treatment to optimize its microstructure, followed by precision CNC machining of the sealing surfaces to guarantee API 598 bi-directional zero-leakage performance.

"JRVAL didn't just sell us a valve; they delivered a tailored engineering solution. Their control over materials and manufacturing gave us the confidence we needed for such a critical application. The valves have performed flawlessly."

Compliance and Capability

We build to global standards. This is not just a claim; it's our manufacturing blueprint. We provide valves that meet your project's exact specifications.

Design & Manufacturing

- ASME B16.34

- API 609 (Category A & B)

- ASME VIII

- AS 2129 / JIS B2220

Flange & Face-to-Face

- Flanges: ANSI, ASME, DIN, EN, BS, JIS, GOST

- Face-to-Face: ISO 5752, MSS SP-68, API 609, EN 558-1

Testing & Actuation

- Testing: API 598, EN 12266-1, ISO 5208

- Leakage: API 598 (Bi-directional Zero Leakage)

- Top Flange: ISO 5211

Our Commitment to Your Project: While we maintain ISO 9001, we know projects often require specific certifications like CE, SIL, or EAC. As a flexible manufacturer, we build our valves to be fully compliant with these standards by design. We can facilitate project-specific third-party certification (e.g., by BV, TUV) upon request, ensuring you only pay for the certification your project truly needs. Contact us to learn more.

Ready to Make the Right Choice?

Don't leave your system's integrity to chance. Discuss your specific application with our engineers, who understand the nuances of material science and fluid dynamics. We'll help you select and configure the perfect valve for performance and long-term value.

Consult Our Experts

JRVAL

JRVAL Aug 05 2025

Aug 05 2025