Beyond the Spec Sheet: Engineering Real-World Reliability

A Case Study on How JRVAL’s Engineered Ductile Iron Butterfly Valves Solved Long-Term Reliability Challenges for a Major Municipal Water Authority in Southeast Asia.

View Our Engineered SolutionTHE CHALLENGE:

THE "GOOD ENOUGH" TRAP

For large-scale municipal projects, components must perform reliably for decades. A leading national infrastructure contractor in Southeast Asia was designing a critical new pumping station.

Chief Project Engineer was wary of specifying standard GGG50 ductile iron valves. "In past projects, we've seen standard valves fail after 5-10 years," he recalled. "External coatings would flake, leading to severe corrosion. Levers would stiffen in our humid climate, and operators lost confidence in achieving a positive shut-off. We needed to eliminate these long-term failure points from day one."

He wasn't just looking for a product. He needed a manufacturing partner who understood the science behind making iron last. He found that partner in JRVAL, a specialized china butterfly valve manufacturer.

The JRVAL Solution

A Philosophy of Verifiable Engineering

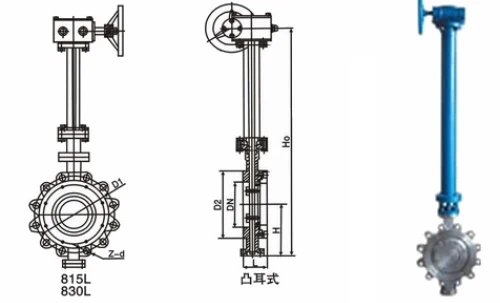

We recognized their challenge was about long-term stability. Our solution was not a single feature, but a holistic manufacturing process applied to our Ductile Iron (EN-GJS-500-7 / GGG50) Lug Type Butterfly Valve, engineered for predictable service.

1. FOUNDATION OF INTEGRITY: CONTROLLED METALLURGY

While many use GGG50, its performance depends on the microstructure. At our butterfly valve factory, we enforce a strict ferritizing annealing heat treatment. This process converts the harder pearlite into a softer, fully ferritic microstructure. This isn't a premium option; it's our standard for creating maximum impact resistance and, critically, a perfectly stable substrate for our coating system.

2. THE DEFENSIVE BARRIER: FUSION-BONDED EPOXY (FBE)

To combat Bangkok's humidity, a simple paint job is insufficient. We apply a 250-micron thick FBE coating (conforming to AWWA C550) onto the annealed, shot-blasted casting. This creates a powerful, chemically bonded barrier that prevents the under-film corrosion and flaking the customer was concerned about. These robust, epoxy coated butterfly valves are built to withstand harsh environments.

3. THE CRITICAL SEAL: TRANSPARENCY IN MATERIAL CHOICE

A valve's body can last for decades, but its service life is dictated by the seal. For this municipal water application, we specified a high-grade EPDM seat butterfly valve. This material offers excellent resistance to chlorine, ozone, and compression set, ensuring a reliable seal. We are transparent that this is a wearable part, but by using a superior grade, we extend its predictable service life and ensure it's the right choice over a standard rubber seat butterfly valve.

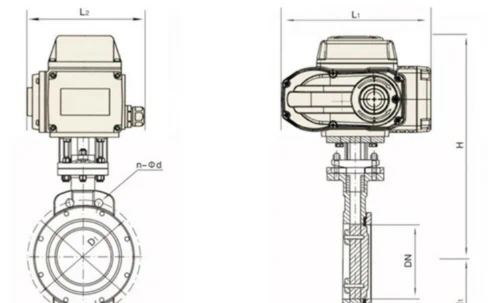

4. THE PROOF: 100% HYDROSTATIC VALIDATION

Promises are meaningless without proof. As a leading lug butterfly valve supplier, our guarantee is our process. Every single PN16 butterfly valve assembly, from a 4 inch butterfly valve to a 24 inch butterfly valve, undergoes rigorous hydrostatic testing per API 598. We conduct a shell test at 1.5x pressure and a bi-directional seat test at 1.1x pressure. This isn't a spot-check; it is a 100% validation that ensures every valve we ship provides the zero-leakage shut-off critical systems demand. Test reports are available for every valve.

THE OUTCOME: VERIFIABLE RELIABILITY

By partnering with JRVAL, the contractor moved beyond a simple spec sheet and invested in a long-term, engineered solution. The outcome was a system built for decades of resilience.

-

Elimination of Corrosion Risk: The FBE coating, bonded to a properly prepared ferritic substrate, provided a robust barrier against the humid climate, preventing the flaking and under-film corrosion seen in previous projects.

-

Assured Zero-Leakage Performance: With 100% hydrostatic testing, the project engineers had complete confidence that every installed valve met the critical zero-leakage requirement from day one.

-

Reduced Long-Term Maintenance Costs: By specifying superior materials (like the high-grade EPDM seat) and processes, the expected service life of the valves was significantly extended, lowering the total cost of ownership.

Build with Confidence. Partner with JRVAL.

For this leading infrastructure contractor, we weren't just a supplier; we were a manufacturing partner who shared their obsession with infrastructure resilience. Our control over the fundamental processes—from metallurgy to coating to seal specification—provided the assurance they needed.

Let our engineering team help you specify the right industrial butterfly valve for your critical application.

Consult Our Engineers

JRVAL

JRVAL Aug 11 2025

Aug 11 2025