Installation Efficiency Boost: A Time Study on Wafer vs. Flange Butterfly Valves

In today's fast-paced industrial projects, time is a critical resource. The choice of valve components can significantly impact project timelines and labor costs. Among industrial butterfly valve options, the debate between the wafer vs flanged butterfly valve designs is pivotal for installation speed. This analysis, backed by JRVAL's extensive manufacturing experience, delves into which type of butterfly valve saves valuable man-hours on-site.

Understanding the Designs: Flange vs. Wafer

Before comparing installation times, it's essential to understand the fundamental structural difference between a double flanged butterfly valve and a wafer butterfly valve.

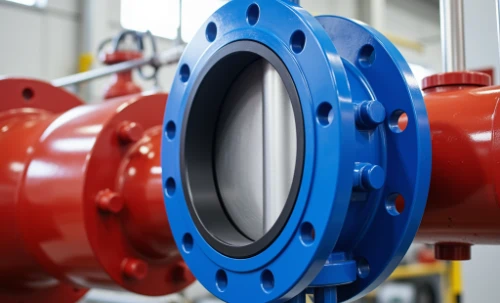

The Traditional Workhorse: Flange Butterfly Valve

A butterfly valve flange type features an integral flange on each end.

The flange butterfly valve, often a double flange type butterfly valve, features a body with two integral flanges. These flanges are designed to connect directly to the flanges of the adjacent pipes. This design requires a separate set of bolts and nuts for each connection (one set connecting the valve's flange to the upstream pipe flange, and another set for the downstream connection). This makes it a robust but component-heavy solution, frequently used in large-diameter pipelines.

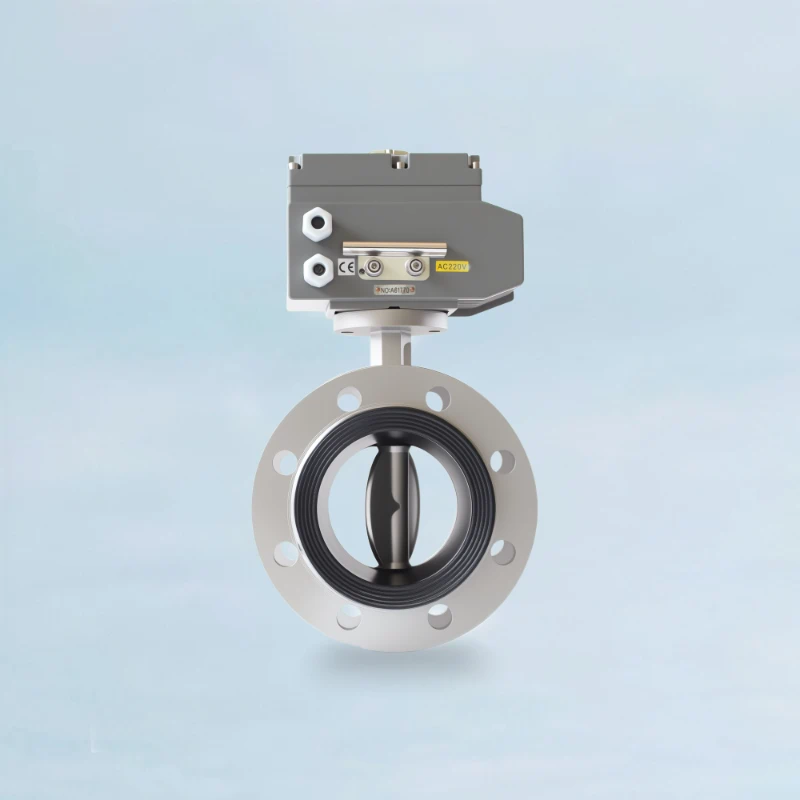

The Efficient Challenger: Wafer Type Butterfly Valve

The wafer style butterfly valve is known for its lightweight, "sandwiched" design.

In contrast, the wafer type butterfly valve has a minimalist body without flanges. It is designed to be "sandwiched" or clamped between two pipe flanges. The entire assembly—pipe flange, wafer valve, and the second pipe flange—is secured by a single set of long through-bolts or studs that extend from one flange to the other. A variation, the lug type butterfly valve, features threaded lugs on the valve body, offering more versatility in installation and removal, a topic we'll explore further. Whether a standard wafer butterfly or a lug wafer butterfly valve, the core principle is a reduction in hardware.

The Head-to-Head Installation Comparison

Analyzing the installation process reveals significant time differences, impacting everything from small HVAC butterfly valve setups to large-scale industrial systems using a 12 inch butterfly valve or larger.

Wafer & Lug Type: The Efficiency Advantages

- Fewer Bolts: This is the single largest time-saver. A wafer style valve requires only one set of long bolts. For an 8-bolt flange, this means installing 8 bolts instead of 16. This halves the time spent on handling, aligning, and tightening bolts.

- Lighter Weight: The compact body of a wafer or lug butterfly valve makes it significantly lighter than its flanged counterpart. A single technician can often handle the installation of a 4 inch butterfly valve or even a 6 inch butterfly valve, reducing labor requirements.

- No Gasket Juggling: Most resilient seated butterfly valves, like those with an EPDM seat butterfly valve design, feature a seat that extends to the valve face, acting as the gasket. This eliminates the need to source and align two separate gaskets, preventing leaks and saving time.

- Simplified Alignment: While requiring care, aligning a lightweight wafer valve can be quicker than maneuvering a heavy flanged valve into the perfect position between two fixed pipes.

Flange Type: The Installation Process

- Double the Bolting: Each flange requires its own complete set of bolts and nuts. For an 8 inch flanged butterfly valve with 8-bolt flanges, this means handling and tightening 16 full bolt-and-nut sets. The labor time multiplies quickly.

- Heavier and Bulkier: The integral flanges add significant weight and size, often requiring mechanical assistance or a two-person team for installation, even for moderately sized valves.

- Two Gaskets Required: Installers must correctly place a gasket on each side of the valve. Misalignment of either gasket can lead to leaks and require a complete re-installation, wasting considerable time.

- Rigid Alignment: While the flanges aid in initial positioning, the valve's weight can make fine adjustments to achieve perfect bolt-hole alignment more cumbersome and time-consuming.

The Verdict: Across various sizes, from a 2 inch butterfly valve to a 24 inch butterfly valve, the installation of a wafer or lug type valve is consistently faster. Field studies and technician feedback suggest that time savings can range from 30% to 50% per valve, a substantial figure when multiplied across an entire project.

How JRVAL's Manufacturing Excellence Maximizes Efficiency

Recognizing the efficiency of wafer and lug designs is only the first step. The quality of the valve itself determines whether these time savings are realized. As a source butterfly valve factory, JRVAL ensures every component enhances installation speed and long-term reliability.

Precision Machining for Flawless Installation

The biggest challenge in lug type butterfly valve installation is bolt alignment and threading. At JRVAL, we leverage our deep expertise in valve machining. Our CNC butterfly valve manufacturing processes ensure that the threaded holes on our lug style butterfly valves are perfectly tapped to standard, eliminating cross-threading and binding issues that plague lower-quality valves. This precision in our butterfly valve machining process means bolts go in smoothly the first time, every time, preserving the speed advantage of the lug design.

From Casting to Assembly: Total Quality Control

JRVAL is not just an assembler; we are a true china butterfly valve manufacturer. Our journey begins with butterfly valve casting, overseen by our founder, a renowned casting expert. We guarantee that the material composition of every wcb butterfly valve or stainless steel butterfly valve (like ss304 or ss316) strictly adheres to international standards such as ASME, DIN, or JIS. This complete control over the supply chain, from raw casting to final butterfly valve assembly, ensures dimensional accuracy and material integrity, preventing on-site fit-up problems.

Innovative Sealing for Guaranteed Performance

A key feature of our product line is bi-directional zero-leakage soft sealing. Through innovative structural design, we achieve this high-performance standard on not just our triple eccentric butterfly valve models, but also on our high performance butterfly valve (double offset) and even standard centerline valve types. This reliability, without added cost, means installers have confidence that once a JRVAL valve is in, it stays sealed, preventing costly rework. Whether it's a PTFE lined butterfly valve for chemical applications or a rubber lined butterfly valve for water service, performance is paramount.

Choose Efficiency with JRVAL's Valve Solutions

As a premier butterfly valve supplier in China, we cater to discerning clients who value quality and performance. Our products are engineered to deliver not just flow control, but also operational efficiency from day one.

Wafer & Lug Type Valves

Our flagship products for fast installation. Experience the benefits of high-precision machining and superior materials in both wafer butterfly and lug butterfly valve configurations.

Explore Wafer & Lug Valves

High-Performance Valves

For more demanding applications, our double offset butterfly valve series offers enhanced durability and our signature zero-leakage sealing technology, available in lug and wafer styles.

View High-Performance Line

Flange Butterfly Valves

For applications where a double flanged design is specified, JRVAL delivers robust, reliable valves built with the same commitment to casting quality and machining precision.

See Flange Valve Options

JRVAL

JRVAL Aug 15 2025

Aug 15 2025