Wafer vs. Flanged Butterfly Valves

A seemingly simple choice that dictates your system's cost, safety, and future. This guide goes beyond basic definitions to the core of engineering practice, helping you make the most informed decision.

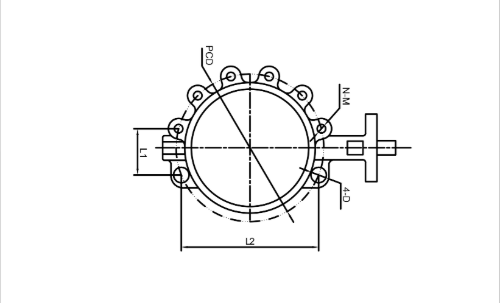

Wafer Butterfly Valve

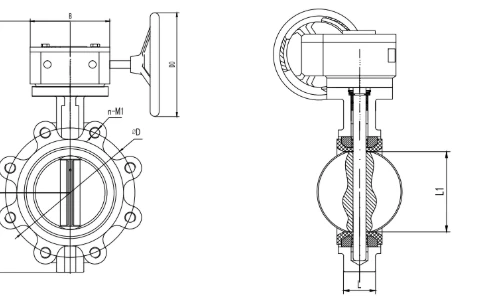

Flanged Butterfly Valve

1. Core Definitions: What Are They?

For the valve novice: Let's grasp the fundamental difference—the connection method—in the most intuitive way.

Wafer Type Butterfly Valve

Imagine a "sandwich." The wafer valve has no flanges of its own, just a few alignment holes. During installation, it's "sandwiched" between two pipe flanges, secured by long bolts (studs) that run from one flange all the way to the other, passing through the valve body. It's the filling in the middle.

- Hallmarks: Compact, lightweight, cost-effective.

- Key takeaway: "Sandwiched" in the middle.

Flanged Type Butterfly Valve

The flanged valve comes with its own "integrated" flanges. The valve body has two flanges cast on its ends, which connect directly to the pipe flanges using two independent sets of bolts. Each connection is separate, like bolting two pieces of equipment together.

- Hallmarks: Robust, high-pressure capability, secure installation.

- Key takeaway: Has its own flanges for independent connections.

2. Decision Matrix: Tailored for Purchasing Managers

Go beyond technical specs. See the business value of each valve type at a glance, focusing on Total Cost of Ownership (TCO), risk, and maintenance ease.

| Decision Factor | Wafer Type | Flanged Type | Winner |

|---|---|---|---|

| Initial Purchase Cost | Less material, simpler construction, significantly lower cost. | Heavier body, more complex casting, higher price point. | Wafer |

| Weight & Space | Extremely light and compact, saving on shipping and installation space. Requires less pipe support. | Bulky and heavy, requiring stronger pipe supports and more operational clearance. | Wafer |

| High-Pressure & Large-Bore Performance | Best for low-to-medium pressure services. Under high pressure, stress concentration on long bolts is a risk. | Exceptional structural rigidity. The undisputed standard for high-pressure (e.g., ASME Class 600+) and large-diameter applications. | Flanged |

| Installation Risk (TCO) | Higher risk. Alignment of long bolts is critical. Overtightening can damage the valve body or seat. | Lower risk. Independent connections. If one bolt fails, it's a simple replacement, posing no risk to the expensive valve body. | Flanged |

| Dead-End Service | Cannot be used. If the downstream pipe is removed, the valve cannot be secured or hold pressure. | Perfectly suited. Can be installed as a terminal valve, reliably holding upstream pressure even with the downstream pipe removed. | Flanged |

| Maintenance Ease | Replacing the valve requires fully loosening both pipe flanges, a cumbersome process. | Allows for removal of downstream piping (for pump/filter maintenance) while the valve remains in place, simplifying work. | Flanged |

Still undecided? Let our engineers analyze your specific operating parameters.

Analyze My Application3. Application Showdown: Which is Best for Your Service?

Where theory meets practice. In real industrial scenarios, the choice becomes clear.

Winner: Wafer

HVAC Systems

Low-pressure service where cost and space are extremely sensitive. The wafer valve's light weight and economy are a perfect match.

Winner: Flanged

Municipal Water Mains

Large diameters (e.g., DN600+) and high system pressures demand maximum structural stability and safety. The flanged valve is the industry standard.

Winner: Wafer

Modular Skid Units

On prefabricated skids, every kilogram of weight and centimeter of space is critical. Wafer valves are the top choice for compact, lightweight designs.

Winner: Flanged

Petrochemical & Power Plants

Involving high temperatures, high pressures, and hazardous media, safety is the top priority. The robust build of flanged valves is non-negotiable.

Winner: Wafer

General Industrial Water Treatment

In most low-to-medium pressure water applications, wafer valves offer the best price-performance ratio, making them ideal for budget-conscious projects.

Winner: Flanged

Desalination (RO High-Pressure Side)

The high pressures (up to 70-80 bar) and corrosive nature of reverse osmosis systems require the safety redundancy only a flanged valve (often in Duplex steel) can provide.

4. In-Depth Case Study: A Senior Engineer's Choice

How the right valve selection averted millions in potential losses on a zero-failure-tolerance project.

Project Background: Cooling Water Pump House for a Major Chemical Complex

A leading global chemical company was designing the cooling water system for its new ethylene plant. The pump house discharge line was the "artery" of the project, where any unplanned shutdown would lead to catastrophic production losses.

Selection Analysis: The EPC Contractor's Internal Debate

Initially, the procurement department favored wafer-style valves to reduce capital expenditure. However, the Chief Engineer objected and led the following in-depth risk assessment:

Option A: Wafer Butterfly Valve

- Pro: Initial purchase cost savings of approx. 30-40%.

- Risk 1 (Installation): A massive DN1200 valve requires extremely long studs for alignment and tightening. This process is difficult and highly prone to uneven stress, which can deform or damage the valve seat.

- Risk 2 (Vibration): Under heavy vibration, the pre-load on the long studs can loosen over time, leading to seal failure or even catastrophic valve displacement.

- Risk 3 (Stress): All stress from pipe expansion/contraction and vibration is concentrated on the valve body's small locating lugs, creating the weakest point in the system.

Option B: Flanged Butterfly Valve

- Pro 1 (Robustness): The valve and pipe flanges form a solid, integrated unit that effectively absorbs and dissipates vibration and pipe stress.

- Pro 2 (Reliability): Two independent sets of bolts ensure a stable, long-term clamping force, eliminating loosening caused by vibration.

- Pro 3 (Safety): Its reliable dead-end service capability provides a crucial layer of safety during maintenance operations.

- Con: Higher initial investment, with corresponding increases in transport and hoisting costs.

Final Decision & The JRVAL Solution

The Engineer's Verdict: A Bet on Reliability

The Decision: The Chief Engineer's analysis prevailed. The EPC concluded that the higher initial cost of flanged valves was a necessary "insurance policy" against the immense cost of potential production downtime.

The JRVAL Contribution: We supplied the project with our DN1200 PN16 Double Flanged Butterfly Valves. The bodies were manufactured from Ductile Iron (QT450-10) for superior strength and toughness. The discs were precision-machined from Duplex Stainless Steel (2205 / ASTM A890 4A) to resist erosion. Critically, every valve underwent rigorous hydrostatic shell (1.5x PN) and seat (1.1x PN) testing, delivered with full MTRs and test reports to guarantee 100% quality and compliance.

Facing a demanding application? Get a robust, tailored solution like this one.

Engineer My SolutionWhy JRVAL? Verifiable Capability, Not Just Claims.

As a source manufacturer, we offer unmatched control over every stage of production. This is our promise of quality, backed by transparent processes you can see.

Source Manufacturer Control

We dictate the exact metallurgical composition in our foundry and oversee every step of heat treatment (e.g., solution annealing, tempering) to ensure superior material properties.

Precision CNC Machining

Our advanced CNC centers guarantee tight tolerances on critical areas like the valve seat and stem packing, ensuring bubble-tight sealing and extended service life.

Guaranteed Zero-Leakage

We don't just meet the standard, we master it. Our soft-seated valves are engineered and individually tested to achieve API 598 bi-directional zero leakage as a baseline requirement.

Unmatched Standard Compatibility

Your project needs DIN flanges, JIS face-to-face, and ASME bodies? No problem. Our flexible production allows us to manufacture valves that are fully compliant with multiple international standards.

OUR 11 PRECISION CNC MACHINING CENTERS

CNC Center 1

CNC Center 2

CNC Center 3

CNC Center 4

CNC Center 5

CNC Center 6

CNC Center 7

CNC Center 8

CNC Center 9

CNC Center 10

CNC Center 11

Curious about our full capabilities? Download our factory brochure.

Download Brochure6. Compliance, Capability & Options

We build to global standards. This isn't just a claim; it's our manufacturing blueprint. We provide valves that meet your project's exact specifications.

Design & Manufacturing

- ASME B16.34

- API 609 (Category A & B)

- ASME VIII

- JIS / BS / DIN

Flange & Face-to-Face

- Flanges: ANSI, ASME, DIN, EN, BS, JIS

- Face-to-Face: ISO 5752, MSS SP-68

- API 609, EN 558-1

Testing & Actuation

- Testing: API 598, EN 12266-1, ISO 5208

- Leakage: API 598 (Bi-directional Zero)

- Top Flange: ISO 5211

Actuation Options

7. Trusted By Industry Leaders

Our commitment to quality has earned us the trust of partners who demand the best.

Lightweight design reduces torque by 40% and energy consumption by 20%, ideal for high-frequency operations.

Standardized design enhances assembly efficiency with strong interface compatibility and simplified installation steps.

High-purity stainless steel ensures 15+ years of service life, stable structure, and outstanding performance.

It's Time to Make the Right Choice

Don't let the wrong valve compromise your project. Contact our engineers today. We'll provide the optimal solution that balances performance and cost-effectiveness for your specific application.

Consult an Expert Now

JRVAL

JRVAL Aug 05 2025

Aug 05 2025