The Ultimate Guide to Butterfly Valve Seat Materials

Don't let a tiny component cause a massive failure. Master the art of selecting the perfect butterfly valve seat for any application.

1. The Foundation of Sealing

Before choosing a material, you must understand the core design. The vast majority of butterfly valves rely on a "resilient seat" for their legendary tight shutoff.

Resilient-Seated Butterfly Valves Defination: The Workhorse

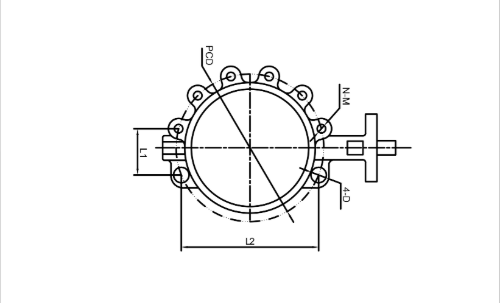

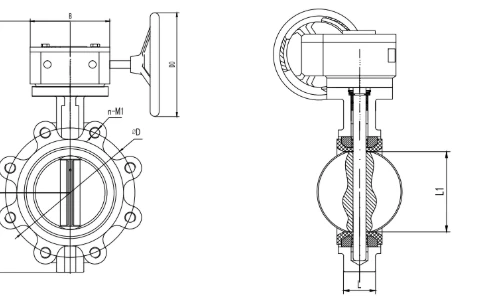

A resilient-seated butterfly valve (also called a soft-seated valve) features a flexible elastomer or polymer (i.e., rubber or plastic) seat. The sealing mechanism is elegantly simple: the metal valve disc compresses into this soft seat, creating an "interference fit." This powerful compression is what provides a bubble-tight, zero-leakage seal.

This seat is typically a one-piece design that lines the entire valve body, often doubling as the flange gaskets, which simplifies installation and reduces potential leak paths.

- Mechanism: Relies on compression and displacement.

- Primary Use: The go-to choice for liquids and gases at low-to-medium pressures and temperatures.

- Key Advantage: Superior sealing performance (Class VI / bubble-tight), cost-effective, and widely available.

2. The Material Roster: A Deep Dive

Here is the most comprehensive breakdown of valve seat materials, organized by family. Understand the strengths and weaknesses of each to find your perfect match.

Group A: Common Elastomers (The Rubbers)

EPDM

The Water Workhorse

Full Name: Ethylene Propylene Diene Monomer

- Excellent For: Water, wastewater, air, glycols, alcohols, alkaline solutions. Superb resistance to weather, ozone, and UV.

- Avoid: Petroleum oils, hydrocarbon fuels, solvents, and greases.

Best Fit: HVAC, municipal water, general industrial water services, food & beverage (with FDA grade).

NBR (Nitrile)

The Oil & Fuel Expert

Full Name: Nitrile Butadiene Rubber

- Excellent For: Petroleum products, hydraulic oils, gasoline, fuels, vegetable oils, and silicone greases.

- Avoid: Ozone, direct sunlight (UV), ketones, steam, and polar solvents.

Best Fit: Fuel handling systems, oil processing, hydraulic machinery, wastewater with oil content.

Group B: Specialty Elastomers

FKM / Viton®

The High-Temp Chemical Defender

Note: FKM, FPM (Europe), and Viton® (a brand name) all refer to the same family of fluoroelastomers.

- Excellent For: A wide range of chemicals, fuels, and oils at high temperatures. Great for mineral acids and halogenated hydrocarbons.

- Avoid: Ketones (like acetone), steam, hot water, and low-temperature applications.

Best Fit: Demanding chemical processing, high-temperature fuel lines, oil & gas industry.

Silicone (SIL)

The Food-Grade & Temperature Specialist

Full Name: Polysiloxane

- Excellent For: Extremely wide temperature range. Food-grade applications, hot/cold air, water. Excellent flexibility at low temps.

- Avoid: Steam, hydrocarbons, acids, and alkalis. Has poor abrasion and tear resistance.

Best Fit: Food & beverage processing, pharmaceutical, high/low-temperature dry air systems.

Hypalon® (CSM)

The Oxidation & Acid Specialist

Full Name: Chlorosulfonated Polyethylene

- Excellent For: Oxidizing chemicals, hot water, and acids like sulfuric and nitric acid. Outstanding weather resistance.

- Avoid: Petroleum oils, solvents, and aromatic hydrocarbons.

Best Fit: Chemical plants, pulp & paper (bleaching), water treatment with chlorine/ozone.

Group C: Fluoropolymers (The Plastics)

PTFE (Teflon®)

The Universal Chemical Warrior

Full Name: Polytetrafluoroethylene

- Excellent For: Near-universal chemical resistance. Acids, bases, solvents. High-purity and food-grade use. Wide temp range.

- Avoid: Abrasive media (can be scratched). Less flexible than rubber, can "cold flow" (deform) under constant load.

Best Fit: Highly corrosive chemical processing, pharmaceutical, food processing. Often bonded to a rubber energizer.

RPTFE

The Stronger PTFE

Full Name: Reinforced Polytetrafluoroethylene

- Excellent For: All the benefits of PTFE but with improved strength and resistance to deformation ("cold flow"), thanks to fillers like glass or carbon.

- Avoid: Similar chemical limitations to the filler material. Can be more abrasive on the valve disc.

Best Fit: Higher pressure and temperature applications where standard PTFE might fail.

UHMWPE

The Abrasion Fighter

Full Name: Ultra-High-Molecular-Weight Polyethylene

- Excellent For: Highly abrasive media like slurries, powders, and mining tailings. Excellent chemical resistance and very low friction.

- Avoid: High temperatures (lower range than PTFE). Not suitable for oxidizing acids.

Best Fit: Mining, cement plants, bulk material handling, and other abrasive slurry applications.

3. The 5-Factor Selection Checklist

Transform knowledge into a decision. Ask these five critical questions to zero in on the perfect seat material for your project.

-

What is the MEDIA? (The #1 Factor)

This is the most important question. Is it water? Oil? A harsh acid? Your answer immediately narrows the field. A chemical compatibility chart is your best friend here.

-

What is the TEMPERATURE Range?

Consider both the normal operating temperature and any maximum/minimum extremes, including cleaning cycles (e.g., steam cleaning). A material's properties can change drastically at temperature limits.

-

What is the PRESSURE?

Most resilient seats perform well up to PN16 / Class 150. Higher pressures can extrude softer materials and may require a stronger seat like RPTFE or even a high-performance metal-seated valve.

-

What is the APPLICATION DUTY?

Is the valve for simple on/off service, or will it be used for throttling/controlling flow? Abrasive media is much more damaging to a seat in a throttling application due to high velocities.

-

Are there REGULATORY Requirements?

Does the application require specific certifications? For example, use WRAS or NSF-61 certified EPDM for drinking water, or FDA-compliant Silicone/PTFE for food processing.

4. At-a-Glance Comparison Chart

Use this quick-reference table to visually compare the key characteristics of each material.

| Seat Material | Temp. Range (Approx.) | Water Resistance | Oil Resistance | Chemical Resistance | Abrasion Resistance |

|---|---|---|---|---|---|

| EPDM | -40°C to 130°C | ||||

| NBR (Nitrile) | -20°C to 90°C | ||||

| FKM (Viton®) | -20°C to 200°C | ||||

| Silicone | -60°C to 200°C | ||||

| Hypalon® | -35°C to 125°C | ||||

| PTFE | -70°C to 230°C | ||||

| RPTFE | -70°C to 250°C | ||||

| UHMWPE | -70°C to 90°C |

Make a Choice That Lasts

Choosing the right seat isn't about picking the "best" material—it's about picking the most **appropriate** one. An incorrect choice can lead to leaks, downtime, and safety risks. Don't leave it to chance.

Contact Our Engineers for a Free Technical Consultation

JRVAL

JRVAL Aug 05 2025

Aug 05 2025