Butterfly Valves for Abrasive & Slurry Service

Moving beyond standard designs. This is an engineer's guide to selecting robust butterfly valves that survive erosion, abrasion, and clogging for maximum uptime and the lowest Total Cost of Ownership (TCO).

TABLE OF CONTENTS

1. Fundamentals

2. Material Science

Why Standard Butterfly Valves Fail in Slurry

Abrasive and slurry services are among the most destructive applications for any valve. Standard resilient-seated butterfly valves, designed for clean liquids and gases, often fail catastrophically within weeks or even days. The primary failure modes include:

- Abrasive Wear: Solid particles in the flow act like sandpaper, rapidly eroding the soft elastomer seat, especially at the 10 and 4 o'clock positions where flow velocity is highest.

- Erosion of the Disc: The valve disc edge is subjected to high-velocity impingement, leading to material loss, compromised shutoff, and eventual structural failure.

- Clogging and Jamming: Slurry can dewater and pack into the space between the disc and body, preventing the valve from opening or closing. This is particularly common in low-flow or static conditions.

- Seat Extrusion: The pressure and abrasive action can push the soft seat out of its groove, causing immediate leakage and making the valve inoperable.

- Stem Sealing Failure: Fine particles can migrate past standard stem seals, abrading the stem and packing, leading to external leakage and seizure of the actuator.

These failures result in costly unscheduled downtime, lost production, safety hazards, and environmental risks. Selecting a valve specifically engineered for these conditions is not a luxury—it is an operational necessity.

Key Design Features for Slurry-Duty Valves

A successful slurry valve is not just about using harder materials. It's a system of integrated design features working together to combat wear and ensure reliability.

1. Protected & Reinforced Seat Design

The seat is the most vulnerable component. Instead of a simple interference-fit seat, look for designs where the seat is mechanically locked or bonded into the body and shielded from the direct flow path. A "recessed" or "protected" seat design ensures that abrasive particles have minimal contact with the primary sealing surface when the valve is open, dramatically extending its life.

2. Hydrodynamically Profiled Disc

A standard flat disc creates significant turbulence, accelerating erosion. A slurry-duty valve should feature a streamlined, contoured disc. This "hydrodynamic" or "spherical" profile minimizes turbulence and presents a smooth path for the slurry to flow over. The leading edge is often hardened or made with a "knife-edge" profile to slice through thick media without creating a damming effect.

3. Robust Stem & Bearing Isolation

To prevent seizure, the stem and bearings must be completely isolated from the process media. Look for features like:

- Live-loaded packing: Multiple V-ring packing sets with Belleville springs automatically adjust for wear and temperature changes, maintaining a constant, tight seal.

- O-ring seals: Redundant O-rings at the top and bottom of the stem provide a secondary barrier against particle ingress.

- Greasable/purged bearings: In extreme cases, bearings with grease fittings or purge ports allow for lubrication and flushing of contaminants.

Exhaustive Material Selection for Abrasive & Slurry Service

Material selection is not a choice, but a calculated engineering decision. Below is an exhaustive breakdown of common and high-performance materials for each critical valve component, rated for their performance in abrasive and corrosive environments.

| Component | Material Specification | Key Characteristics & Primary Use Case | Abrasion Resistance | Corrosion Resistance |

|---|---|---|---|---|

| Body Materials: The Foundation of Pressure Containment | ||||

| Body | Ductile Iron (GGG40 / GGG50) | Workhorse for general services. Excellent strength and cost-effectiveness for non-corrosive slurries (e.g., water-based tailings). | Fair | Poor |

| Carbon Steel (WCB / WCC) | The standard for flanged valves in hydrocarbon and steam services. Higher strength and temperature capability than cast iron. | Fair | Poor | |

| Low-Temp Carbon Steel (LCB / LCC) | Specifically for low-temperature and cryogenic applications, retaining toughness where WCB becomes brittle. | Fair | Poor | |

| Stainless Steel (CF8/CF3, CF8M/CF3M) | CF8M (316) is the industry standard for corrosion resistance. CF3M (316L) used for welded parts. CF8 (304) is a lower-cost alternative for less corrosive media. | Good | Good | |

| Duplex & Super Duplex (2205/2507) | Superior strength and chloride corrosion resistance compared to stainless steel. The go-to for seawater, brine, and many chemical slurries. | Good | Excellent | |

| Aluminum Bronze (C954 / C958) | Premier choice for seawater and marine applications due to exceptional resistance to corrosion and bio-fouling. | Fair | Excellent | |

| Super Austenitic / Hastelloy (1.4529 / HC276) | Reserved for the most aggressive chemical environments (e.g., high concentration acids, wet chlorine gas) where other alloys fail. | Fair | Ultimate | |

| Disc Materials: The First Line of Defense | ||||

| Disc | Ductile Iron (DI) + Coating (e.g., Nylon-11, Halar®) | Base-level option where a coating provides the primary resistance. Suitable for low-abrasion, low-velocity slurries. Coating integrity is critical. | Poor (Fair with coating) | Poor (Good with coating) |

| Stainless Steel (CF8/304, CF8M/316) | General purpose choice for mildly corrosive and abrasive services. Prone to pitting in chloride environments. | Fair | Good | |

| Duplex SS (e.g., 2205 / CD3MN) | Excellent combination of high strength and superior corrosion resistance to standard stainless steels. A workhorse for many slurry types. | Good | Excellent | |

| Super Duplex SS (e.g., 2507 / CE3MN) | Enhanced strength and resistance to pitting/crevice corrosion, especially in high-chloride or sour gas environments. | Good | Ultimate | |

| Super Austenitic SS (e.g., 1.4529 / 904L) | Designed for highly corrosive conditions, particularly sulfuric acid and high-chloride media, where Duplex may not suffice. | Fair | Ultimate | |

| Aluminum Bronze (C95400 / C95800) | Excellent for seawater, brine, and applications requiring resistance to bio-fouling. Moderate abrasion resistance. | Fair | Good | |

| Hastelloy® (HC276) | Premium nickel-chromium-molybdenum alloy for extremely corrosive chemical slurries (acids, wet chlorine gas, etc.). | Fair | Ultimate | |

| Stellite® Overlay (Grade 6 or 21) | A hardfaced layer welded onto a base disc (e.g., SS316). Provides an outstanding combination of hardness, toughness, and corrosion resistance. The industry standard for severe service. | Excellent | Excellent | |

| Tungsten Carbide Coating (HVOF) | A thermally sprayed coating providing hardness exceeding Stellite. Excellent for fine particle erosion but can be brittle under high-impact loads. | Excellent | Good | |

| Solid Ceramic (Alumina / Zirconia) | Offers the highest possible resistance to sliding abrasion from fine particles. Chemically inert. The ultimate choice for applications like fly ash or mineral processing. | Ultimate | Ultimate | |

| UHMWPE Lined Disc | Ultra-High Molecular Weight Polyethylene provides an extremely low-friction, slick surface with exceptional sliding abrasion resistance. Best for fine, non-cutting particles. | Excellent | Good | |

| Stem Materials: Ensuring Operability | ||||

| Stem | Carbon Steel (45#) / SS 410/416/420 | Standard, cost-effective options. Require a dry, non-corrosive stem sealing area. Martensitic SS provides hardness for high torque. | Poor | Poor |

| Stainless Steel (SS304 / SS316) | Industry standard for general corrosive resistance. SS316 offers better resistance to chlorides than SS304. | Poor | Good | |

| 17-4PH (UNS S17400) | Precipitation-hardened stainless steel. Offers an excellent combination of high strength (for high torque) and good corrosion resistance. | Fair | Good | |

| Duplex / Super Duplex (2205 / 2507) | Used when stem material must match the disc for corrosion resistance in aggressive media, while also providing superior strength. | Fair | Excellent | |

| Monel® K500 | Nickel-copper alloy, age-hardened for high strength. Exceptional resistance to seawater, hydrofluoric acid, and alkalis. | Fair | Excellent | |

| Hastelloy® (HC276) | Specified in the most severe corrosive environments to prevent stem failure due to chemical attack. Matches HC276 disc. | Fair | Ultimate | |

| Soft Seat Materials: The Primary Seal | ||||

| Soft Seat | EPDM / NBR | EPDM: Excellent for water, steam, alcohols. Poor for oils. NBR: Excellent for petroleum, oils. Moderate abrasion resistance for both. | Fair | Poor-Fair |

| FKM (Viton®) / Hypalon® | FKM: High temperature and broad chemical resistance. Hypalon: Good for acids and weathering. Both offer fair abrasion resistance. | Fair | Good | |

| PTFE / RPTFE | Virtually universal chemical resistance. Non-elastic, requires specific valve geometry. RPTFE (Reinforced) has better mechanical stability but still limited abrasion resistance. | Poor | Ultimate | |

| Polyurethane (PU) | Offers exceptional tear strength and resistance to sliding abrasion from sharp particles. The premier choice for many abrasive mining slurries. | Excellent | Fair | |

| UHMWPE | Ultra-High Molecular Weight Polyethylene. Best-in-class for sliding abrasion resistance in fine slurries. Extremely low friction prevents material buildup. | Ultimate | Good | |

| Natural Rubber (NR) | Excellent for water-based slurries with fine particles due to its high resilience ("bounce-back"). Poor oil and chemical resistance. | Good (Fine Slurry) | Poor | |

| Metal Seat & Sealing Systems: For Extreme Conditions | ||||

| Metal Seat | Integral or Hardfaced Body Seat | Used in metal-seated valves (HPBFV, TOV). The seat is machined into the body and overlaid with Stellite® or Tungsten Carbide for wear resistance. | Excellent | Excellent |

| Laminated Disc Seal Ring | Core of a Triple Offset Valve. A flexible, multi-layer ring (e.g., SS316 + Graphite, Duplex + Graphite) is compressed against the body seat, providing a bubble-tight metal seal. | Good | Excellent | |

| Solid Metal Disc Seal Ring | A solid metal ring (e.g., SS316, Inconel®) used in place of a laminated one in TOVs for very high pressure, high temperature, or severe abrasive services where graphite is unsuitable. | Good | Excellent | |

Slurry Valve Type Comparison

How does a slurry-duty butterfly valve compare to other common solutions like knife gate valves?

| Feature | Slurry-Duty Butterfly Valve | Knife Gate Valve | Standard Butterfly Valve |

|---|---|---|---|

| Throttling Ability | Good (with profiled disc) | Poor (causes gate vibration) | Fair (causes high wear) |

| Shutoff Performance | Excellent (Zero Leakage) | Good (metal-to-metal or elastomer seal) | Poor (seat quickly fails) |

| Footprint / Weight | Excellent (Compact & Light) | Poor (Tall & Heavy) | Excellent (Compact & Light) |

| Cost (Initial) | Moderate | Moderate | Low |

| Total Cost of Ownership (TCO) | Low (long life, low maintenance) | Moderate (packing needs frequent service) | High (frequent replacement) |

Comprehensive Standards: The Engineer's Framework

Specifying a valve without referencing standards is an engineering oversight. These standards provide the non-negotiable framework for safety, interchangeability, and performance verification. Below is a detailed breakdown of critical international standards.

American Standards (API, ASME)

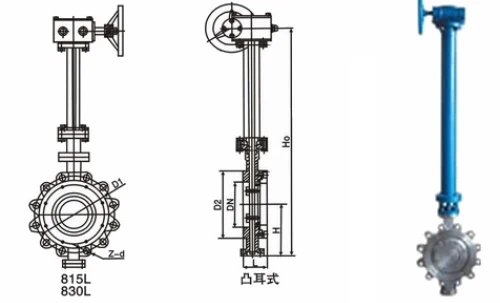

- API 609: The cornerstone for butterfly valve design, covering lug, wafer, and flanged types.

- API 598: Dictates factory inspection and testing protocols.

- ASME B16.34: Defines pressure-temperature ratings for valve body materials.

- ASME B16.5 / B16.47: Governs flange dimensions and tolerances.

International & European Standards

- EN 593: The primary European standard for industrial butterfly valves.

- ISO 5752 / EN 558: Specifies the critical face-to-face dimensions for interchangeability.

- ISO 5211: Standardizes actuator mounting dimensions (top flange).

- EN 1092-1 / -2: Governs flange types and dimensions for steel and iron.

German & British Standards

- DIN 3202: German standard defining face-to-face dimensions, often harmonized with EN 558.

- DIN 3354: General requirements for metal butterfly valves.

- BS 5155: British standard for butterfly valves, now largely superseded by EN 593.

- BS 4504: British standard for circular flanges, often cross-referenced.

Japanese & Chinese Standards

- JIS B2032: Japanese Industrial Standard for wafer-type rubber-lined butterfly valves.

- JIS B2220: Standard for pipe flanges, defining 5K, 10K, 20K ratings.

- GB/T 12238: Chinese national standard for general purpose industrial butterfly valves.

- GB/T 9113: Chinese standard for integral steel pipe flanges.

| DN | NPS (inch) | API 609 | EN 558 (ISO 5752, DIN 3202) | ||

|---|---|---|---|---|---|

| Cat. A (Wafer) | Cat. B (Lug/Flg) CL150 | Series 20 (Wafer) | Series 13/14 (Flg) | ||

| 50 | 2 | 43 | 48 | 43 | 127 |

| 65 | 2.5 | 46 | 51 | 46 | 140 |

| 80 | 3 | 46 | 48 | 46 | 152 |

| 100 | 4 | 52 | 54 | 52 | 190 |

| 150 | 6 | 56 | 57 | 56 | 222 |

| 200 | 8 | 60 | 64 | 60 | 292 |

| 250 | 10 | 68 | 70 | 68 | 330 |

| 300 | 12 | 78 | 76 | 78 | 356 |

| 350 | 14 | 78 | 83 | 78 | 381 |

| 400 | 16 | 92 | 89 | 92 | 406 |

| 500 | 20 | 108 | 108 | 108 | 502 |

| 600 | 24 | 114 | 121 | 114 | 597 |

| 750 | 30 | 140 | 140 | 140 | 698 |

| 900 | 36 | 165 | 159 | 165 | 794 |

| 1000 | 40 | 184* | 184* | 184* | 991* |

| 1200 | 48 | 216* | 216* | 216* | 1194* |

| DN | NPS | Flange OD (mm) | Flange Thk (mm) | Raised Face Dia (mm) | No. of Bolts | Bolt Dia (inch) |

|---|---|---|---|---|---|---|

| 80 | 3 | 190.5 | 23.9 | 127.0 | 4 | 5/8 |

| 100 | 4 | 228.6 | 23.9 | 157.2 | 8 | 5/8 |

| 150 | 6 | 279.4 | 25.4 | 215.9 | 8 | 3/4 |

| 200 | 8 | 342.9 | 28.4 | 269.7 | 8 | 3/4 |

| 250 | 10 | 406.4 | 30.2 | 323.8 | 12 | 7/8 |

| 300 | 12 | 482.6 | 31.8 | 381.0 | 12 | 7/8 |

| 350 | 14 | 533.4 | 35.1 | 412.8 | 12 | 1 |

| 400 | 16 | 596.9 | 36.6 | 469.9 | 16 | 1 |

| 500 | 20 | 711.2 | 42.9 | 577.8 | 20 | 1 1/8 |

| 600 | 24 | 812.8 | 46.0 | 685.8 | 20 | 1 1/4 |

| 750 | 30 | 984.2 | 52.3 | 844.6 | 28 | 1 1/4 |

| 900 | 36 | 1162.0 | 57.2 | 1016.0 | 32 | 1 1/2 |

| 1050 | 42 | 1346.2 | 62.0 | 1193.8 | 36 | 1 1/2 |

| 1200 | 48 | 1524.0 | 66.8 | 1371.6 | 44 | 1 1/2 |

| Material | ASTM Spec. | -29 to 38°C | 100°C | 200°C | 300°C | Class Rating |

|---|---|---|---|---|---|---|

| Carbon Steel | A216 WCB | 19.6 | 17.7 | 15.8 | 13.8 | Class 150 |

| LT Carbon Steel | A352 LCB/LCC | 19.6 | 17.7 | 15.8 | 13.8 | Class 150 |

| Stainless Steel | A351 CF8M | 19.6 | 16.6 | 14.0 | 12.1 | Class 150 |

| Duplex SS | A890 4A (CD3MN) | 19.6 | 17.7 | 15.8 | 13.8 | Class 150 |

| Carbon Steel | A216 WCB | 51.1 | 46.6 | 43.8 | 41.9 | Class 300 |

| LT Carbon Steel | A352 LCB/LCC | 51.1 | 46.6 | 43.8 | 41.9 | Class 300 |

| Stainless Steel | A351 CF8M | 51.1 | 45.1 | 39.8 | 36.4 | Class 300 |

| Duplex SS | A890 4A (CD3MN) | 51.1 | 48.8 | 46.0 | 43.8 | Class 300 |

| DN | 50 | 80 | 100 | 150 | 200 | 250 | 300 | 400 | 600 | 900 | 1200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (kg) | 4 | 6 | 8 | 14 | 25 | 40 | 58 | 115 | 270 | 750* | 1400* |

|

*Footnote (Per Protocol 1.2.2): The data for sizes DN900 and larger is a based on engineering principles and typical industry data. Weights can vary significantly (+/- 20%) based on manufacturer, specific design (e.g., body thickness), and materials of construction. This data is for preliminary planning and logistical estimation only. Final, certified weights must be obtained from the manufacturer for detailed engineering and lifting plans. |

|||||||||||

Actuation & Automation in Slurry Service

In abrasive environments, the actuator is as critical as the valve. An undersized or improperly specified actuator will fail, rendering the entire assembly useless. Key considerations include:

1. Torque Calculation & Safety Factors

Slurry introduces significant resistance beyond the standard "seating" and "dynamic" torques. A "slurry factor" or "packing factor" must be added to the calculation. This accounts for the extra force needed to shear through dewatered or packed solids that can accumulate around the disc.

- Break Torque: The initial force to unseat the valve. This can be extremely high if solids have settled.

- Running Torque: The force required to move the disc through the slurry flow.

- Reseating Torque: The force to drive the disc back into the seat against flow and slurry packing.

- Safety Factor: For clean service, a safety factor of 1.25 to 1.5 (25-50% extra torque) is common. For light slurry, this should increase to 1.5-2.0. For heavy, dewatering slurry, a safety factor of 2.0 to 3.0 (100-200% extra torque) is often necessary to guarantee operation.

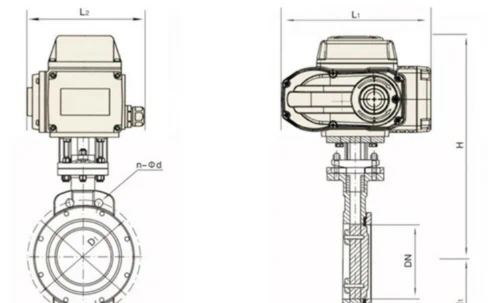

2. Actuator Type Selection

- Pneumatic Scotch Yoke / Rack & Pinion: The workhorses of valve automation. Scotch yoke actuators provide high torque at the start and end of the stroke, which is ideal for breaking open and seating slurry valves. They are robust and reliable.

- Electric Actuators: Offer precise control and feedback. They must be sized with an adequate safety factor and duty cycle for the application. Ensure the enclosure (e.g., NEMA 4X/6P) is sufficient to protect electronics from washdowns and corrosive atmospheres.

- Hydraulic Actuators: Provide the highest torque output and are suitable for very large valves or high-pressure applications where pneumatic or electric options are impractical.

Product Recommendations for Specific Applications

Based on the engineering principles above, here are targeted valve recommendations for common abrasive services.

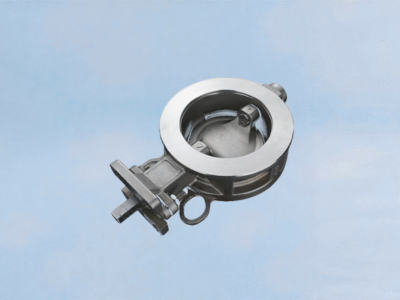

Concentric Lined Butterfly Valve

- Application: General purpose water-based slurries, tailings, pulp & paper (white liquor).

- Disc: Duplex SS (CD3MN) or Halar® Coated DI

- Seat: UHMWPE or Polyurethane (PU) for maximum abrasion resistance.

- Key Feature: Cost-effective, replaceable liner design with excellent shutoff.

High-Performance Butterfly Valve (HPBFV)

- Application: Moderate pressure, higher temperature, or mildly abrasive chemical slurries.

- Disc: Super Duplex or Stellite® Hardfaced

- Seat: RPTFE or UHMWPE for a balance of chemical and abrasion resistance.

- Key Feature: Double offset design reduces seat wear during modulation.

Triple Offset Butterfly Valve (TOV)

- Application: Severe service: high pressure, high temperature, abrasive and corrosive catalytic slurries, fly ash.

- Disc: Stellite® Hardfaced Super Duplex

- Seat: Integral Stellite® Hardfaced Body Seat

- Key Feature: Friction-free, torque-seated metal-to-metal seal provides zero-leakage shutoff in the most demanding conditions.

Frequently Asked Questions

Quick answers to common questions about specifying butterfly valves for abrasive service.

Can I use a butterfly valve to throttle slurry?

Yes, but only a valve designed for it. A High-Performance (HPBFV) or Triple Offset (TOV) valve with a profiled disc and hardened trim is suitable for throttling. A standard concentric valve should primarily be used for on/off service, as partial opening will focus wear on the elastomer seat and cause premature failure.

What is more important: disc material or seat material?

They are equally critical and must be treated as a system. A hard disc with a soft seat will simply abrade the seat faster. A soft disc with a hard seat will result in disc erosion. The materials must be chosen together based on the specific slurry's particle size, hardness, and corrosivity.

How does a Triple Offset Valve (TOV) handle slurry without a soft seat?

A TOV uses a unique geometry where the disc seal (a laminated metal/graphite or solid metal ring) contacts the body seat (typically Stellite) only at the moment of final closure. This cone-in-cone seating is non-rubbing, or "camming," which avoids the friction and wear that destroys other valve types. This makes it exceptionally durable in abrasive applications.

Engineered Butterfly Valves

Ready to configure a valve for your slurry application?

JRVAL

JRVAL Aug 12 2025

Aug 12 2025