Asia-Pacific's Infrastructure Boom: How JRVAL is Positioning for Emerging Markets?

As nations across the Asia-Pacific (APAC) region invest trillions into new infrastructure, the demand for reliable, high-quality industrial components is soaring. JRVAL, a specialized butterfly valve factory, is strategically positioned to meet this demand by leveraging its unique source-to-solution manufacturing model and engineering expertise.

The APAC region is a global hotspot for infrastructure development, creating immense opportunities.

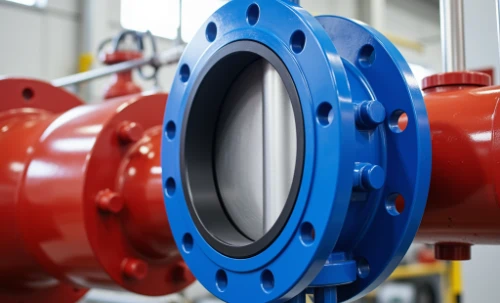

The APAC region is undergoing a historic transformation. From massive water treatment facilities in Vietnam and Indonesia to new industrial parks in Thailand and expanding port facilities in the Philippines, development is rampant. At the heart of these projects are complex fluid control systems that depend on the performance of industrial valves. A faulty valve can lead to costly downtime, safety hazards, and project delays. This environment demands more than just components; it requires reliable partners who can deliver quality and precision. The versatile butterfly valve, known for its compact design and efficient operation, has become a cornerstone of these projects, and manufacturers of butterfly valves are playing a crucial role.

JRVAL's Advantage: The Power of a Source Factory

Unlike many suppliers, JRVAL operates as a true source butterfly valve factory, maintaining complete control over the entire production lifecycle. This integrated approach is our fundamental advantage.

Our process begins where quality is born: in the foundry. With a legacy rooted in casting and a founder recognized as a regional casting expert, we bring over 20 years of metallurgical experience to every product. This deep expertise in butterfly valve casting ensures that the material integrity of every valve body, from a standard wcb butterfly valve to a high-grade stainless steel butterfly valve, meets or exceeds client specifications. We follow this with high-precision valve machining and meticulous butterfly valve assembly, ensuring that every finished product, whether it's a wafer butterfly valve or a complex triple eccentric butterfly valve, adheres to the highest quality standards. This end-to-end control allows us to guarantee performance and traceability, a critical factor for infrastructure projects with long service life expectations.

Core Strengths Engineered for APAC's Demands

JRVAL's strategy for emerging APAC markets is built on four pillars of excellence that directly address the challenges and needs of modern infrastructure projects.

1. Advanced Bi-Directional Sealing Technology

A primary selling point of our valves is the bi-directional soft-seal zero-leakage performance. Through innovative structural design rather than added material costs, we achieve bubble-tight shutoff in both directions. This advanced sealing isn't limited to high-end models; it is a feature across our range, including our double eccentric butterfly valve and even our standard centerline valve products. For projects in water treatment and industrial processing, this reliability translates to enhanced safety and operational efficiency.

2. Superior Machining for Flawless Installation

We recognize that on a busy construction site, time is money. That's why we place immense focus on the precision of our valve machining. A key example is our lug type butterfly valve, where the high accuracy of the threaded bolt holes significantly simplifies and speeds up installation. This attention to detail ensures a perfect fit, reduces labor time, and eliminates common installation issues, making our lug butterfly valve a preferred choice for contractors and engineers.

3. Unmatched Flexibility for Diverse Standards

The APAC region is not a monolith; each country has its own set of standards and requirements. JRVAL's production flexibility is a significant competitive advantage. We can configure our manufacturing lines to produce a single batch of valves adhering to multiple international standards—such as API 609, DIN, or JIS 10K. This "specialized standard" capability allows us to serve diverse project needs efficiently, providing customized solutions for clients without the typical delays or high costs associated with bespoke orders. Whether a project requires a PN16 butterfly valve or an ASME valve, we can deliver.

4. Strategic Focus on Quality for SMEs

As a source factory, we offer a natural price advantage over major international brands. However, our focus is not on being the cheapest, but on offering the best value. We target small and medium-sized enterprises (SMEs) and mid-sized projects that require high-quality, reliable flow control solutions without the premium price tag. Our products, backed by ISO, CE, BV, and marine-grade certifications, provide a robust and dependable choice for industrial and marine butterfly valve applications, positioning JRVAL as the smart alternative for quality-conscious clients.

Partner with a Reliable Butterfly Valve Supplier

JRVAL is more than a manufacturer; we are a dedicated partner for growth in the Asia-Pacific. Our factory-direct model, engineering prowess, and commitment to quality make us the ideal choice for your next infrastructure project.

Rubber Lined Butterfly Valves

Our core range of resilient-seated valves, including the popular lug and wafer type butterfly valve, offers cost-effective and reliable shutoff for water, HVAC, and general industrial services.

Explore Centerline Valves

High Performance Butterfly Valves

Engineered for high-cycle applications. Features like an eccentric disc design, robust bearings, and superior seat materials (EPDM/RPTFE) prevent premature wear and ensure consistent, low-torque operation, reducing actuator stress and long-term energy costs.

Explore HPBV

JRVAL

JRVAL Aug 30 2025

Aug 30 2025