From Chronic Failure to Asset Reliability in a Copper Slurry Application

This technical review documents how a major copper concentrator in the Andes region solved a critical reliability issue in their tailings lines, drastically cutting maintenance costs and eliminating unplanned shutdowns by deploying our engineered slurry-service butterfly valves.

The Challenge: Catastrophic Valve Failure in Abrasive Slurry Service

A copper concentrator plant was experiencing chronic failures of their isolation valves on the tailings thickener underflow lines. The application is notoriously harsh:

- Media: Copper concentrate slurry with 35% solids content.

- Abrasion: Hard, angular silicate particles up to 250 microns (60 mesh).

- Operating Conditions: 7 bar (100 psi) pressure, ambient temperature, frequent cycling for line isolation.

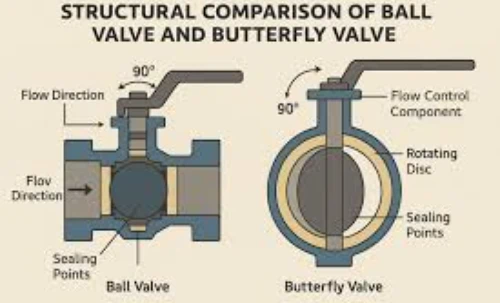

The plant was using conventional, soft-seated (EPDM) centric butterfly valves. These valves were failing at an alarming rate, with an average service life of only 4-6 months. The failure mode was consistently a catastrophic tearing and erosion of the rubber seat, which led to two critical problems:

- Inability to Isolate: The leaking valves could not provide positive shutoff, making pump maintenance hazardous and time-consuming, often requiring a full line drain.

- Unplanned Shutdowns: A major seat failure would halt the entire tailings circuit, costing the operation an estimated $45,000 per event in lost production and recovery.

The Solution: An Engineered Defense Against Abrasion

The plant's reliability engineering team sought a solution that prioritized service life and TCO over initial unit price. We proposed our Triple-Offset Metal-Seated Butterfly Valve, specifically designed for abrasive service.

Hardened Sealing Surfaces: Stellite® 6 Hard-Facing

The core of our solution is replacing the vulnerable rubber seat with a robust metal-to-metal seal. The integral body seat and the disc sealing edge are overlaid with Stellite® 6 (cobalt-chromium alloy). This hard-facing (avg. 40 HRC) is highly resistant to the sliding and erosive wear from slurry particles, ensuring a long-lasting, tight shutoff (ANSI/FCI 70-2 Class V).

Minimized Wear Geometry: Triple-Offset Design

Unlike centric valves where the disc rubs the seat for the full 90° of travel, our triple-offset geometry provides a "cam" effect. The disc lifts off the seat almost immediately upon opening, drastically reducing friction and wear during throttling or cycling. This preserves the integrity of the hard-faced sealing surfaces.

Built for Mining Duty: Robust Construction

The valves were supplied with Duplex 2205 bodies for superior strength and corrosion resistance, and a full-lug body design for dead-end service. The stem is protected by a live-loaded packing system, preventing abrasive slurry from migrating into the bearing areas and causing stem seizure—a common secondary failure mode.

Results: A Paradigm Shift in Reliability and Cost

Sixteen valves were installed as direct replacements. The performance after 30 months has fundamentally changed the plant's maintenance strategy and financial outlook for this part of the circuit.

30+ Months

Continuous Operation Without Failure

0

Valve-Related Unplanned Shutdowns

98%

Documented 3-Year TCO Reduction

3-Year Total Cost of Ownership (TCO) Analysis (Per Valve)

| Cost Factor | Previous Soft-Seated Valve | Our M700 Metal-Seated Valve |

|---|---|---|

| Initial Unit Cost (CAPEX) | \$650 | \$2,200 |

| Expected Service Life | ~6 Months | >3 Years (in this service) |

| Replacement Events (3 Years) | 5 | 0 |

| Replacement & Labor Cost | 5 events x \$1,500 = \$7,500 | \$0 |

| Cost of Unplanned Downtime | 5 events x \$45,000 = \$225,000 | \$0 |

| Total 3-Year TCO | \$233,150 | \$2,200 |

"We were burning through soft-seated valves every few months. Each failure was a fire drill and a huge production hit. The Stellite-seated valve was a significant upfront investment, but it justified its entire CAPEX in the first prevented shutdown. After 30 months, they perform like new. This is what 'reliability' actually looks like."

Maintenance Superintendent, (Anonymous) Copper Concentrator

Stop Replacing Valves. Start Investing in Uptime.

In abrasive applications, the cheapest valve is always the most expensive. Our engineered slurry valves are purpose-built to deliver predictable service life in the most demanding environments.

Contact our application engineers to discuss your specific slurry conditions. We'll provide a technical solution and a transparent TCO model to prove the value to your entire team, from maintenance to finance.

Solve My Slurry Valve Problem

JRVAL

JRVAL Aug 18 2025

Aug 18 2025