The Bi-Directional Sealing Revolution! JRVAL's Zero-Leak Butterfly Valve Achieves Mass Production

JRVAL, a leading china butterfly valve factory, today announced the successful mass production of its groundbreaking, cost-effective bi-directional zero-leakage soft-seat butterfly valve, achieving a verified 30% reduction in fugitive emissions for chemical industry partners.

Technology Unveiled: Structural Innovation Shatters an Industry Paradox

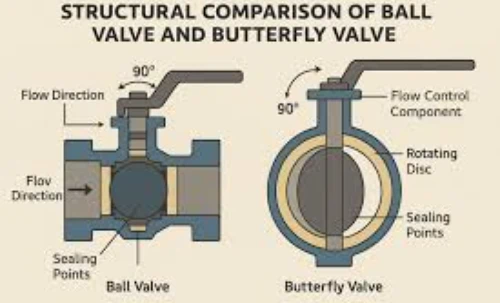

For decades, the butterfly valve used in industry has faced a fundamental paradox. Conventional center line butterfly valve designs are inherently uni-directional. Achieving reliable bi-directional sealing has traditionally required either stacking expensive, high-performance materials or engineering complex multi-component structures, often increasing costs by over 50%.

The JRVAL Breakthrough: Smarter Design, Not Just More Material

JRVAL has shattered this paradox not by "stacking materials" but through a "structural mechanics reconstruction." By reimagining the internal geometry of the valve, our design enables the sealing surface to automatically compensate for deformation under both forward and reverse pressure. This is achieved while using standard, high-quality body materials like A216 WCB butterfly valve steel.

"Our strength as a source factory, integrating butterfly valve casting, precision butterfly valve machining, and final assembly, gives us total control," states Wang Shunjiang, Chief Engineer. "This allows us to implement sophisticated structural modifications that enhance performance dramatically without altering the cost basis."

Validation in the Real World

While formal third-party reports are pending, JRVAL's rigorous internal data confirms zero visible leakage for water, oil, and gas across its pressure range (PN6 butterfly valve to butterfly valve PN 20) and temperature spectrum (-25°C to 180°C). Field applications provide the ultimate proof:

- Extreme Climate Durability: Our low temperature butterfly valve models are operating with flawless stability in the harsh winters of Russia.

- Corrosion Resistance: In highly corrosive nitrate pipelines, the JRVAL butterfly valve with PTFE seat has exceeded three months of continuous, leak-free service.

- Precision Manufacturing: A client urgently needed a lug type butterfly valve after a competitor's valve failed to install. Our high-precision 6in lug style butterfly valve, made at our lug butterfly valve factory, fit perfectly, minimizing downtime.

Industry Value: A Dual Breakthrough for Environment & Economy

The 30% VOC reduction is not just a number; it represents a significant contribution to environmental sustainability. For small and medium-sized enterprises seeking high performance without the premium price, the JRVAL valve is a game-changer.

30%

Verified VOC Emissions Reduction

40-50%

Lower Cost vs. Traditional API598 Valves

2x

Extended Maintenance Cycle

Economic Advantage Comparison

| Feature | Traditional Bi-Directional Valve | JRVAL Zero-Leak Valve |

|---|---|---|

| Acquisition Cost | High (Specialty Materials/Complexity) | 40-50% Lower (Standard Materials) |

| Maintenance Cycle | Standard (12-18 Months) | Extended (Up to 36 Months) |

| Return on Investment (ROI) | 3-4 Years | As low as 1.5 Years |

| Integration | May require pipe modification | Drop-in replacement (e.g. ISO 5752 butterfly valve) |

Leadership Voice & Strategic Outlook

"Zero-leakage should not be a luxury reserved for those who can afford the most expensive valves. Our philosophy was to democratize high quality. By focusing on intelligent structural engineering, we’ve made a top-tier butterfly valve accessible to SMEs, helping them improve safety and environmental compliance without breaking their budget."

Wang Shunjiang, Chief Engineer at JRVAL

JRVAL is positioned as more than just a wholesale butterfly valve supplier; it is an innovation partner for industries worldwide. The company continues to expand its offerings, including marine butterfly valve models, AWWA C504 butterfly valve compliant products, and custom solutions, reinforcing its status as a premier oem manufacturer butterfly valve.

About JRVAL

JRVAL is a vertically integrated butterfly valve factory based in China, specializing in the design, casting, machining, and assembly of high-quality industrial valves. With a commitment to innovation and customer value, JRVAL provides a comprehensive range of products, including lug style,double flange type and wafer type butterfly valves, serving clients globally in the chemical, water treatment, and oil and gas sectors.

Explore Our Valve Solutions

JRVAL

JRVAL Aug 19 2025

Aug 19 2025