Engineering for Uptime: A High-Pressure Desalination Case Study

This case study demonstrates how a major coastal water authority resolved persistent operational failures by transitioning from standard valves to our vertically integrated, precision-engineered Lug Type Butterfly Valve, ensuring process integrity in a demanding SWRO environment.

View ResultsThe Challenge: When "Standard" Valves Become a Liability

For any large-scale Seawater Reverse Osmosis (SWRO) desalination plant, continuous operation is an economic and civic necessity. Every component is subjected to a relentless combination of high pressure (often exceeding 60 bar), extreme salinity, and the constant threat of crevice and pitting corrosion. The failure of even a single isolation butterfly valve can lead to costly downtime, inefficient energy use, and significant maintenance challenges.

The maintenance team at a major Middle Eastern desalination facility faced recurring issues with their existing butterfly valves in critical service lines. Their problems were twofold, creating a significant operational risk.

Key Issues Faced:

- Seal Failure & Unidirectional Limitation: The previous valves, while pressure-rated, frequently developed seat leaks. Many were a common rubber lined butterfly valve design that couldn't handle the aggressive brine. Critically, their seals were effective in only one direction, making the isolation of pipe sections for repair a complex and often unsafe procedure during back-pressure events.

- Material Degradation & Premature Failure: Valves were failing prematurely. The maintenance superintendent noted, "We saw it all: stem corrosion on the actuated butterfly valve units leading to high operating torque, pitting on the disc surface, and even signs of porosity in the valve body discovered during replacement. These weren't just leaks; they were integrity failures. We needed a butterfly valve supplier who controlled the product from the metal up, a true china butterfly valve manufacturer with in-house foundry and engineering capabilities."

The Solution: A Vertically Integrated Approach to Reliability

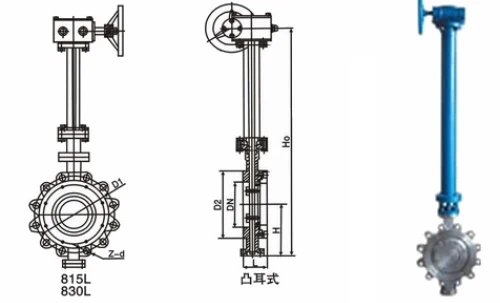

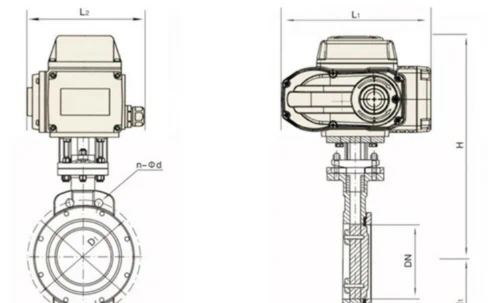

We presented the facility with our Series 700 Lug-Type Butterfly Valve, a solution engineered specifically for the harsh realities of seawater service. As a leading name among manufacturers of butterfly valves, our approach was not just about providing a product, but about demonstrating end-to-end control over its creation, from raw material to final butterfly valve assembly.

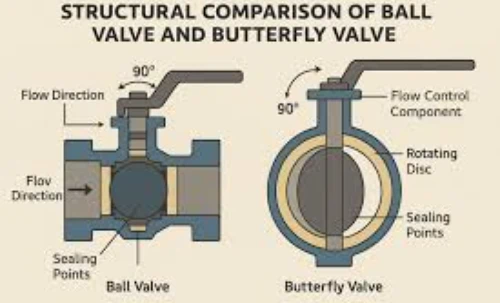

The Core Innovation: Bi-Directional Zero-Leakage Sealing

The primary challenge of seal integrity was addressed through structural innovation. Unlike a standard soft seat butterfly valve, our Series 700 features a dynamically energized, pressure-assisted EPDM seat butterfly valve. The seat profile is engineered to use both upstream and downstream line pressure to create a tighter seal against the disc. This, combined with a spherically machined and polished disc edge, ensures a true bi-directional, bubble-tight shutoff (0 leakage), even after thousands of cycles. This butterfly valve resilient seat design inherently provides the dual-direction isolation that the plant's maintenance protocol required, a feature often lacking in a standard center line butterfly valve.

Foundry-First Integrity: Guaranteed Material Control

As a butterfly valve factory founded by casting experts, we understand that performance begins with molten metal. For this corrosive seawater application, all valve bodies and discs were cast from ASTM A351 CF8M butterfly valve grade (316 Stainless Steel), with Duplex and Super Duplex options available for the most aggressive brine lines. Every batch of raw material undergoes Positive Material Identification (PMI) spectral testing, guaranteeing the critical chromium, nickel, and molybdenum content strictly adheres to ASTM standards. This ensures our stainless steel butterfly products offer maximum resistance to chloride-induced corrosion.

Precision CNC Machining: The Key to Perfect Sealing

The most innovative seat design is useless without geometric perfection from precise valve machining. Our multi-axis CNC centers ensure that every component's dimensions—from the valve bore to the stem hole and disc edge on every single butterfly valve ss316 unit—are machined to exceptionally tight tolerances. This precision is critical for the perfect concentric alignment between the disc and seat, which is non-negotiable for achieving our guaranteed bi-directional zero-leakage performance. This level of quality makes us a leading lug butterfly valve supplier and sets our industrial butterfly valve products apart. The result is a reliable butterfly lug type valve with low, consistent operating torque over its entire lifespan.

Our 11 Precision CNC Machining Centers

CNC Center 1

CNC Center 2

CNC Center 3

CNC Center 4

CNC Center 5

CNC Center 6

CNC Center 7

CNC Center 8

CNC Center 9

CNC Center 10

CNC Center 11

Results and Impact: From Liability to Asset

The installation of over 200 Series 700 Butterfly Valves, including various sizes like the 4 inch butterfly valve and 8 inch butterfly valve, transformed the facility's operations. After 18 months of continuous service, the impact was clear and quantifiable.

0

Valve-Related Unplanned Shutdowns

100%

Isolation Success in Leak Detection

40%

Projected 5-Year Maintenance Cost Reduction

"With these valves, we aren't just buying a component; we're buying confidence. Knowing that the material is verified from the china butterfly valve factory and that the design is proven gives us the reliability we need to keep the water flowing. The bi-directional seal on this lug valve isn't just a feature—it's solved one of our biggest operational headaches."

Maintenance Superintendent, Major Coastal Desalination Project

Partner with a Proven Butterfly Valve Supplier

Your process reliability shouldn't be compromised by component failure. Whether you need a PN16 butterfly valve, a high-temperature PTFE lined butterfly valve, or a large diameter butterfly valve for a demanding industrial application, our engineering team is ready to help.

As a leading butterfly valve supplier china, we provide engineered solutions that deliver quantifiable performance and long-term asset integrity. Contact us to discuss your specific challenges.

Consult Our Desalination Experts

JRVAL

JRVAL Aug 13 2025

Aug 13 2025