Understanding the Butterfly Valve

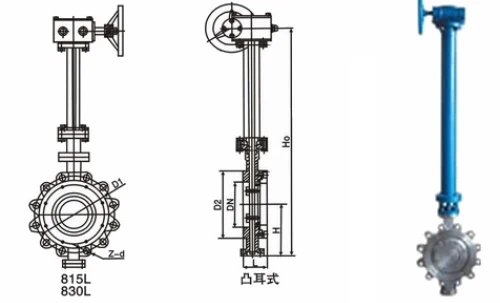

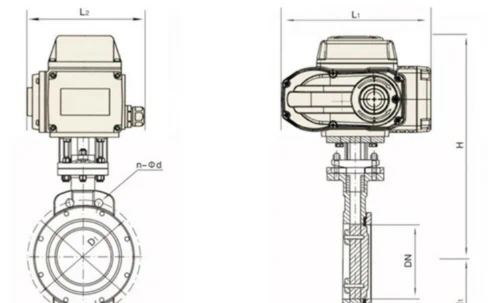

Known for its simplicity, compact design, and cost-effectiveness, the butterfly valve is a staple in many industries for on/off and throttling services.

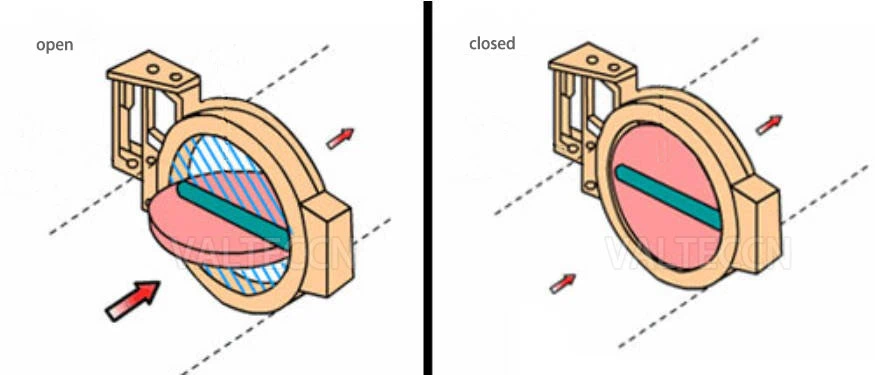

A butterfly valve controls flow with a quarter-turn rotating disc, offering a simple and fast operation.

【image source: https://www.valteccn.com/blog/butterfly-valve-article/how-do-i-know-if-the-manual-butterfly-valve-is-open-or-closed/】

Core Operating Principle

A butterfly valve is a quarter-turn valve, meaning a 90-degree rotation of the stem moves the valve from fully open to fully closed. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned to completely block the passageway. When the valve is fully open, the disc is rotated a quarter turn to be parallel to the flow, allowing fluid to pass with minimal restriction.

Primary Advantages

- Low Cost & Lightweight: Simple construction and fewer materials make them significantly cheaper and lighter than globe valves, especially in large sizes.

- Low Pressure Drop: The thin disc presents minimal obstruction to flow when fully open, resulting in very low head loss and better energy efficiency.

- Fast Acting: The quarter-turn operation allows for rapid opening and closing, making them ideal for emergency shut-off applications.

- Compact Footprint: Their wafer or lug design has a very short face-to-face dimension, requiring minimal installation space.

Primary Disadvantages

- Limited Throttling Precision: The valve's flow characteristic is non-linear, making precise flow control difficult. High flow velocities can also cause disc flutter and damage.

- Disc in Flow: The disc is always present in the flow path, causing some turbulence and a minor pressure drop even when fully open.

- Cavitation Risk: In high-pressure-drop throttling situations, cavitation can occur, which may damage the disc and seat.

Understanding the Globe Valve

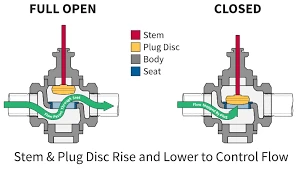

When precise flow regulation is the top priority, the globe valve is the industry's go-to solution, prized for its excellent throttling capabilities.

A globe valve uses a movable plug and a complex flow path to achieve superior flow control.

[ image sorce: https://assuredautomation.com/actuated-valve-training/types-of-valves.php?srsltid=AfmBOoryHceTTMueVQGELwNQHw8nML3p97xEXGO7vs1SrZ4xfFaiH9ot]

Core Operating Principle

A globe valve is a linear motion valve used to stop, start, and regulate flow. It operates by moving a plug (or disc) perpendicular to the seat. The internal Z-shaped or S-shaped passageway forces the fluid to change direction multiple times. This tortuous path is the key to the valve's ability to break down pressure and control flow with high precision, as the flow rate is directly proportional to the travel of the stem.

Primary Advantages

- Excellent Throttling: Unmatched capability for precise, repeatable flow regulation across the entire range of stem travel.

- Superior Shut-off: The disc seats firmly and squarely against the valve seat, providing a very tight, reliable seal, often meeting stringent leak-rate classes.

- Good for Frequent Operation: The design is robust and well-suited for applications that require frequent opening, closing, and modulation.

- Easy Maintenance: The seat and plug are generally easy to access and resurface or replace without removing the valve body from the pipeline.

Primary Disadvantages

- High Pressure Drop: The S-shaped flow path inherently creates significant resistance, leading to high head loss and increased pumping energy costs.

- High Cost & Heavy Weight: More complex construction and greater material requirements make them heavier and more expensive than butterfly valves.

- Slow Operation: Requires multiple turns of the handwheel or a long-stroke actuator, making it slower to operate than a quarter-turn valve.

- Large Footprint: Globe valves are bulky and require more installation space and structural support.

Head-to-Head Comparison: Butterfly vs. Globe Valve

Now, let's put these two valves side-by-side across the most critical performance and commercial metrics.

| Feature | Butterfly Valve | Globe Valve |

|---|---|---|

| Flow Control & Throttling | Poor to Fair. Best suited for on/off or rough control. Non-linear characteristic can cause "jumps" in flow rate and control instability. High-performance designs offer better, but still not linear, control. | Excellent. The undisputed champion for precise, linear flow modulation. Ideal for any application where setting and maintaining a specific flow rate is critical (e.g., chemical dosing, temperature control). |

| Pressure Drop (Energy Loss) | Very Low. The streamlined disc in the open position creates minimal obstruction, resulting in significant energy savings over the system's lifetime, especially in large-scale applications. | Very High. The tortuous, S-shaped flow path inherently causes a large pressure drop, even when fully open. This translates to higher pumping costs and is a major design consideration. |

| Shut-off Capability (Sealing) | Good to Excellent. Resilient-seated valves provide bubble-tight shut-off. High-performance and triple-offset designs can achieve zero-leakage performance, suitable for critical applications. | Excellent. The plug seats perpendicular to the flow, providing a highly reliable and tight seal. Globe valves are often specified when the tightest possible shut-off is required by code or process safety. |

| Size, Weight & Footprint | Extremely compact and lightweight. The face-to-face dimension is very small, drastically reducing installation space, piping support requirements, and shipping costs. | Bulky and Heavy. Significantly larger and heavier than a butterfly valve of the same nominal size, requiring more substantial piping support and a larger installation envelope. |

| Cost (Initial & Lifetime) | Lower initial cost. The simpler design and lower material usage make it a much more economical choice upfront, particularly for pipe sizes above DN100 (4"). | Higher initial cost. The complex body casting and more intricate internals lead to a significantly higher purchase price. Lifetime cost can also be higher due to energy loss from pressure drop. |

| Actuation Requirements | Low torque. The quarter-turn mechanism requires less force to operate, allowing for smaller, lighter, and less expensive actuators (manual, pneumatic, or electric). | High thrust. The linear motion against system pressure requires high force (thrust), necessitating larger, more powerful, and more expensive actuators. |

| Typical Applications | Large-volume water/wastewater, HVAC, cooling water systems, chemical processing (on/off), bulk solids handling, vacuum service. Ideal for general-purpose isolation. | Cooling water systems, fuel oil lines, steam lines (vents, drains), feedwater and chemical feed systems, turbine lube oil systems. Anywhere precise flow regulation is the primary goal. |

The Decision Guide: When to Choose Which?

Ultimately, the choice isn't about which valve is "better," but which is the "right" tool for the job. Use this simple checklist to guide your decision.

Choose a Butterfly Valve if...

- Your primary need is simple on/off service.

- You are working with a large pipe diameter (e.g., > DN150 / 6").

- Minimizing pressure drop and energy consumption is a key priority.

- Space, weight, and initial budget are major constraints.

- Rapid opening or closing is required.

Choose a Globe Valve if...

- Precise and repeatable flow regulation (throttling) is non-negotiable.

- The application requires frequent flow rate adjustments.

- A very tight, high-integrity shut-off is critical for safety or process control.

- The system can tolerate a high pressure drop as a trade-off for control accuracy.

- The service involves high-pressure steam or fluids.

Conclusion: The Right Valve for the Right Job

The contrast between butterfly and globe valves highlights a fundamental engineering trade-off. Butterfly valves champion efficiency, cost-effectiveness, and compactness for general isolation tasks. Globe valves, in contrast, provide unparalleled precision and control at the expense of higher cost and energy loss. By carefully evaluating your application's specific needs against the distinct strengths and weaknesses of each design, you can ensure optimal performance, safety, and economy for your fluid control system.

Butterfly or Globe Valve?

Our experts can help you specify the correct valve for your project.

JRVAL

JRVAL Aug 12 2025

Aug 12 2025