Beyond the Spec Sheet: Engineering Decades of Reliability

A Case Study on How JRVAL's Engineered Ductile Iron Lug Type Butterfly Valves Solved Long-Term Corrosion and Sealing Challenges for a Major Municipal Water Authority in Southeast Asia.

Explore The Engineered SolutionTHE CHALLENGE:

THE HIGH COST OF "GOOD ENOUGH"

A leading national infrastructure contractor was designing a critical new pumping station for a municipal water authority in a high-humidity coastal region. The Chief Project Engineer, Mr. Chen, was tasked with ensuring a 25-year service life for every industrial butterfly valve.

"Our experience with standard, off-the-shelf ductile iron butterfly valve products was a key concern," Mr. Chen explained. "On previous projects, we saw lug style butterfly valves that met the initial PN16 butterfly valve spec begin to fail prematurely. Painted coatings would blister and flake within 5-7 years, leading to corrosion. Critically, operators reported inconsistent sealing, forcing them to over-torque the gearboxes on the butterfly valve type lug."

He needed more than a simple butterfly valve supplier. He required a true china butterfly valve manufacturer who could provide a verifiable, engineered solution to mitigate these specific, long-term failure modes and justify a lower Total Cost of Ownership (TCO).

The JRVAL Engineered Solution

A System Built on Process Control

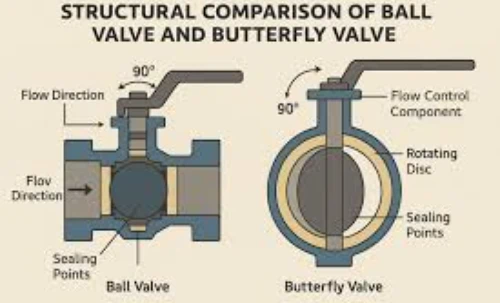

As an expert lug butterfly valve manufacturer, we knew the client's problem wasn't the material itself, but the lack of process control in standard manufacturing. Our solution was a systematic approach applied to our Ductile Iron (GGG50) fully lugged butterfly valve, focusing on the root causes of failure.

1. Metallurgical Foundation: Annealing for Adhesion

This process is essential for creating a uniform, stable surface on the butterfly valve casting. It's the critical first step to ensure our coating system achieves a permanent chemical bond. This level of control over the initial casting and subsequent valve machining is fundamental to the quality of every lug valve we produce at our butterfly valve factory.

2. The Corrosion Barrier: AWWA FBE Coating

We applied a 250-micron minimum thickness Fusion-Bonded Epoxy (FBE) coating, conforming to AWWA butterfly valve standards. These robust, epoxy coated butterfly valves resist impact, abrasion, and saline environments, forming a true defensive barrier that is far superior to a standard blue butterfly valve paint job.

3. Seal Integrity: Engineered EPDM

To address inconsistent sealing, we specified a high-grade EPDM seat butterfly valve. Our design also ensures the seat is isolated from media flow when open, reducing wear. This choice ensures our rubber seat butterfly valve (a type of soft seat butterfly valve) provides superior, predictable service life and simplifies maintenance planning for the client.

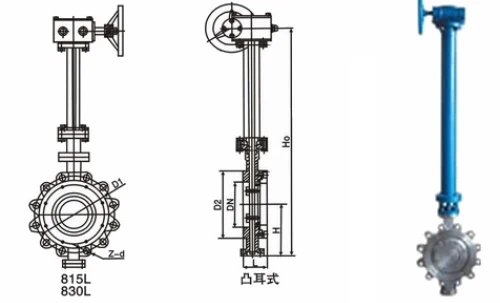

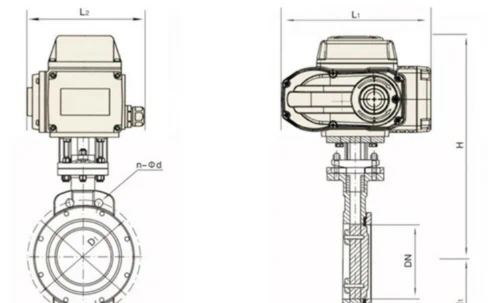

4. The Guarantee: 100% Verifiable Testing

Our quality protocol mandates that every single lug butterfly valve, from a 4 inch butterfly valve to a large diameter butterfly valve like a 24 inch butterfly valve, undergoes rigorous hydrostatic testing per API 598. This guarantees zero-leakage performance, essential for any butterfly valve for flow control, with reports traceable to each valve.

THE OUTCOME: FROM SPECIFICATION TO CERTAINTY

By focusing on the root causes of long-term failure, JRVAL, as a premier lug butterfly valve supplier, delivered a solution that transformed risk into confidence. The project now benefits from quantifiable improvements.

-

Mitigated Corrosion Risk: The superior FBE coating on these epoxy coated butterfly valves provided a verifiable, long-term barrier against environmental corrosion.

-

Assured Operational Performance: 100% traceable test reports for each 6 inch butterfly valve and 12 inch butterfly valve provided documented proof of zero-leakage performance.

-

Reduced Total Cost of Ownership (TCO): By extending the service life of each DI butterfly valve, the contractor could lower unplanned downtime and replacement costs over the facility's lifecycle.

Your Challenge is Our Blueprint.

For critical infrastructure, "good enough" is never the answer. Real value lies in partnering with a butterfly valve from china manufacturer who understands the science behind durability.

Let's discuss the specific challenges of your next project. Contact us for your wholesale lug butterfly valve and other industrial valve requirements.

Consult Our Engineers

JRVAL

JRVAL Aug 12 2025

Aug 12 2025