Case Study Path

CASE STUDY: FROM HIGH-RISK SOURCING TO A RELIABLE PARTNERSHIP

For EPCs executing large-scale water treatment projects (Desalination, RO), material integrity is paramount. Sourcing high-specification valves like Super Duplex from multiple traders introduces immense risk of counterfeit materials, conflicting documentation, and customization roadblocks, jeopardizing project integrity and timelines.

THE VERTICALLY-INTEGRATED SOLUTION

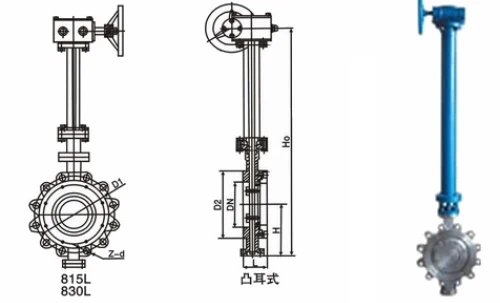

JRVAL partnered with an international EPC to deliver a comprehensive, engineered butterfly valve package for a critical water treatment facility. By leveraging our in-house foundry and advanced machining capabilities, we provided a single-source solution that guaranteed material authenticity, accommodated custom requirements, and de-risked the entire procurement process.

| System Application & Conditions | Key Challenges & Procurement Risks | The JRVAL Engineered Solution | Verifiable Value & Risk Mitigation |

|---|---|---|---|

| High-Pressure RO Feedwater DN600, Super Duplex Steel, High-salinity. |

|

|

Direct Material Control. Full traceability from melt to machining in our 81,426 m² facility. We guarantee a PREN > 40, verified by in-house QC reports. Client-sponsored third-party testing welcomed for ultimate assurance. |

| Seawater Intake System Large diameter (up to DN2000), low pressure. |

Balancing long-term corrosion resistance against budget constraints for large-scale, general service valves. Ensuring coating integrity is critical for asset life. |

|

Lifecycle Cost Optimization. A proven, robust design protected by a verifiable marine-grade coating system that prevents premature failure and costly replacement, optimizing the Total Cost of Ownership (TCO). |

| Dosing & Chemical Treatment Aggressive media (chlorine, acids). |

Standard elastomers fail rapidly when exposed to treatment chemicals. Requires specialized material knowledge to prevent leaks and downtime. |

|

Deep Application Expertise. We provide a chemically inert valve solution that protects system integrity, prevents hazardous leaks, and ensures personnel and environmental safety. |

OUTCOME: TOTAL PROJECT CERTAINTY

By consolidating the valve package with a source manufacturer, the EPC mitigated critical project risks, streamlined their procurement process, and secured a more reliable and cost-effective long-term outcome for the end-user.

Verifiable Material Integrity

The client gained direct access to the source of manufacturing. Our in-house foundry and 11 CNC machining centers mean we control quality at every step. This eliminated the risk of counterfeit materials and provided a single, transparent standard of documentation.

Simplified & De-Risked Procurement

One purchase order, one engineering contact, and one accountable partner. This saved significant administrative overhead, eliminated conflicting documentation, and ensured every custom requirement was met without compromising the project timeline.

Optimized Project Cost & Support

By engaging directly with us, the EPC avoided reseller markups. Furthermore, our 2-year comprehensive warranty with free spare parts and responsive online technical support provides long-term operational assurance far beyond simple product delivery.

"For our critical infrastructure projects, material authenticity is non-negotiable. The market is saturated with suppliers offering suspect documentation. JRVAL gave us a level of transparency we hadn't seen before by having direct control over their own foundry. They delivered the custom-dimensioned Duplex valves that were critical for our retrofit, with a verifiable material quality that satisfied our end-client's stringent requirements. They are not just a supplier; they are a manufacturing partner."

JRVAL

JRVAL Aug 18 2025

Aug 18 2025