A Compendium of Butterfly Valve Bearing Materials

An exhaustive engineering guide to the selection, specification, and application of bearing and bushing materials for butterfly valves. This archive details metallic, polymeric, and composite options, complete with quantitative data and international standard cross-references to ensure optimal performance, low torque, and maximum service life.

TABLE OF CONTENTS

1. Fundamentals

2. Material Data Tables

3. Engineering & Standards Data

The Critical Role of Bearings in Butterfly Valves

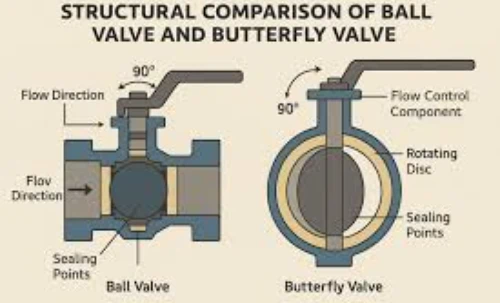

Often overlooked, the stem bearing (or bushing) is a pivotal component that dictates the performance, reliability, and lifespan of a butterfly valve. Its primary functions are not merely supportive; they are integral to the valve's core operation. A correctly specified bearing system achieves four critical objectives: it provides low-friction support for the stem, ensuring smooth and predictable actuation torque; it maintains precise alignment of the disc within the valve body, which is essential for proper sealing; it isolates the stem from the valve body, preventing galvanic corrosion and galling (cold welding) between similar metals; and it absorbs the radial forces exerted on the disc by fluid flow, protecting the stem from bending and fatigue. The failure of a bearing, a seemingly minor component, can lead to catastrophic valve failure, resulting in stem seizure, leakage, and costly operational downtime.

Key Selection Criteria for Bearing Materials

The selection of an appropriate bearing material is a multi-faceted engineering decision, balancing mechanical, thermal, and chemical properties against cost and service life expectations. The primary criteria include:

- PV Limit (Pressure-Velocity): The most critical tribological parameter. It defines the material's upper limit for the combination of bearing pressure (P) and surface velocity (V) under which it can operate without catastrophic failure due to frictional heat buildup. Exceeding the PV limit leads to rapid wear and seizure. Expressed in MPa·m/s or psi·fpm.

- Coefficient of Friction (μ): A measure of the resistance to motion between the bearing and the stem. A low coefficient of friction (especially static friction, or "stiction") is paramount for reducing actuator torque requirements, preventing jerky operation, and minimizing energy consumption.

- Compressive Strength & Load Capacity: The maximum compressive stress the material can withstand without permanent deformation (creep) or structural failure. This is critical in large-diameter or high-pressure valves where radial forces are significant.

- Temperature Range: The material must maintain its mechanical properties and dimensional stability across the entire operating temperature range of the application, from cryogenic lows to high-temperature process fluids.

- Chemical Compatibility: The bearing must be chemically inert to the process fluid, cleaning agents, and any ambient atmospheric corrosives. Degradation by chemical attack leads to swelling, loss of strength, and premature failure.

- Wear & Abrasion Resistance: In services with particulate matter, the bearing must resist abrasive wear. For all services, it must resist adhesive wear (galling) when in contact with the stem material.

- Dimensional Stability: Refers to the material's resistance to changing size due to thermal expansion or moisture absorption. High stability is crucial for maintaining proper clearances and preventing seizure.

2.1 Metallic Bearing Materials

Metallic bearings offer high strength, excellent temperature resistance, and superior load-bearing capacity. They are the traditional choice for high-pressure and high-temperature services. However, they typically require lubrication (from the process fluid or grease) and careful material pairing with the stem to prevent galling.

| Material / Common Name | UNS No. | Key Characteristics & Application | Max Temp (°C) | Tensile Str. (MPa) | Hardness (HB) | Galling Resistance |

|---|---|---|---|---|---|---|

| Leaded Tin Bronze (SAE 660) | C93200 | The industry "workhorse". Excellent lubricity and embeddability from lead content. General-purpose, lubricated services. Good machinability. | 230 | 241 | 65 | Excellent |

| High-Leaded Tin Bronze (SAE 64) | C93700 | Higher lead content than C93200 provides superior anti-seizure properties for high-speed, low-load applications. Excellent for marginally lubricated systems. | 230 | 207 | 60 | Ultimate |

| Tin Bronze ("Navy G") | C90500 | Good corrosion resistance, especially in marine environments. Higher strength than leaded bronzes. General hardware and pump components. | 260 | 276 | 75 | Fair |

| Aluminum Bronze | C95400 | High strength, excellent corrosion resistance (seawater), and good wear resistance. Requires a hardened and polished stem. High-load, high-strength applications. | 260 | 586 | 170 | Fair |

| Manganese Bronze | C86300 | Very high tensile strength, designed for high-load, low-speed applications. Used for heavy-duty valve bearings requiring maximum strength. Poor galling resistance. | 200 | 758 | 225 | Poor |

| Oil-Impregnated Bronze (Sintered) | CT-1000-K26 (SAE 841) | Porous bronze (P/M) is vacuum-impregnated with oil, providing self-lubrication. Ideal for applications where external lubrication is impossible. | 100 | 124 | 40 | Excellent |

| Material / Treatment | UNS / Grade | Role in Bearing System & Key Characteristics | Hardness | PREN¹ | Galling (Self) |

|---|---|---|---|---|---|

| Note: These materials typically form the stem (shaft) or hardfaced bore that the bearing runs against. | |||||

| Martensitic SS (Stem) | S41000 (410) / S42000 (420) | Base material for stems requiring hardness for high torque. Must be paired with a softer bearing (bronze, PTFE). Limited corrosion resistance. | 35-50 HRC | ~13 | Very Poor |

| Precipitation Hardening SS (Stem) | S17400 (17-4PH) | Excellent combination of high strength (from hardening) and good corrosion resistance (better than 400 series). A premium stem material. | ~44 HRC (H900) | ~17 | Poor |

| Duplex / Super Duplex (Stem) | S32205 / S32750 | High strength combined with excellent resistance to chloride-induced corrosion. Used in seawater, chemical processing. | ~28 HRC | 35 / >40 | Poor |

| Nitrogen-Strengthened Austenitic SS | S21800 (Nitronic™ 60) | Specifically designed for superior galling resistance, even in metal-to-metal contact. Can be used as both stem and bearing for unique situations. | ~95 HRB | ~24 | Ultimate |

| Nickel Alloy (Stem) | N05500 (Monel K500) | Age-hardenable nickel-copper alloy with excellent corrosion resistance, especially in marine and chemical services. High strength and toughness. | 27-38 HRC | N/A | Poor |

| Surface Hardening & Overlays | |||||

| Stellite™ 6 Overlay | (ERCoCr-A) | Cobalt-chromium alloy welded onto the stem or body bore. The industry standard for severe service. Extremely hard, corrosion-resistant, and galling-resistant. | ~40 HRC | N/A | Ultimate |

| Hard Chrome Plating | N/A | An electroplated layer of chromium on a base metal stem. Provides a very hard, low-friction surface. Can be susceptible to damage in corrosive environments. | 66-70 HRC | N/A | Fair |

| Nitriding / QPQ | N/A | A thermochemical case-hardening process that diffuses nitrogen into the surface of a steel stem, creating a hard, wear-resistant layer. | 55-70 HRC | N/A | Good |

|

¹ Pitting Resistance Equivalent Number (PREN) = %Cr + 3.3 * %Mo + 16 * %N. It is a theoretical measure of a stainless steel's resistance to localized pitting corrosion in chloride-containing environments. A higher PREN value indicates greater resistance. Generally, PREN > 32 is considered resistant to seawater. |

|||||

2.2 Polymeric Bearing Materials

Polymeric bearings are prized for their self-lubricating properties, excellent chemical resistance, and ability to embed small particulates, protecting the stem from scoring. Their primary limitations are lower load capacity and a more restricted temperature range compared to metals.

| Material Family | Specific Grade / Filler | Key Characteristics & Application | Max Temp (°C)¹ | PV Limit (MPa·m/s) | Load Capacity (MPa) | Notes |

|---|---|---|---|---|---|---|

| Fluoropolymers | ||||||

| PTFE (Polytetrafluoroethylene) | Virgin / Unfilled | Lowest coefficient of friction of any solid. Excellent chemical inertness. Limited by low strength, high cold flow (creep), and poor wear resistance. Used in low-load, full-liner designs. | 260 | 0.03 | 3.5 | Foundation for all other PTFE compounds. |

| RPTFE (Reinforced PTFE) | 15-25% Glass Fiber Filled | The most common RPTFE. Significantly improved wear resistance and compressive strength. Good for water, solvents, and general chemicals. Abrasive to soft stems. | 260 | 0.35 | 12 | Not suitable for hydrofluoric acid or strong alkalis. |

| 25-35% Carbon Fiber Filled | Higher compressive strength and lower coefficient of friction than glass-filled. Electrically conductive. Good in water and non-oxidizing media. | 260 | 0.42 | 14 | Can cause galvanic corrosion with some metals. | |

| 60% Bronze Filled | Highest compressive strength and best wear resistance of PTFE compounds. High thermal conductivity dissipates frictional heat. Not for corrosive service. | 260 | 0.52 | 16 | Limited to non-corrosive, lubricated applications. | |

| 15% Graphite Filled | Graphite reduces friction and improves initial wear-in. Often blended with other fillers like carbon. Good for dry-running applications. | 260 | 0.40 | 8 | Softer than glass or carbon-filled grades. | |

| High-Performance Engineering Plastics | ||||||

| PEEK (Polyetheretherketone) | Unfilled (Victrex™ 450G) | High strength, excellent chemical resistance, and high temperature capability. The baseline for high-performance polymer bearings. | 250 | 0.45 | 24 | Can be attacked by concentrated H₂SO₄. |

| Carbon/Graphite/PTFE Filled (Bearing Grade) | Optimized for tribology. Significantly lower friction and wear rate than unfilled PEEK. The premier choice for demanding dry-running polymer bearing applications. | 250 | 1.20 | 28 | e.g., Victrex™ 450FC30 | |

| 30% Carbon Fiber Filled | Highest strength and stiffness of PEEK grades. Excellent load capacity and heat dissipation. More abrasive than bearing grades. | 250 | 1.00 | 35 | e.g., Victrex™ 450CA30 | |

| PAI (Polyamide-imide) | Bearing Grade (e.g., Torlon® 4301) | Superior compressive strength and temperature resistance to PEEK. Excellent wear resistance. Often used where PEEK bearings fail due to load or temperature. | 275 | 1.40 | 38 | Susceptible to hydrolysis in high-temp water/steam. |

| PI (Polyimide) | Graphite Filled (e.g., Vespel® SP-21) | Maintains properties at extreme temperatures (cryogenic to 300°C+). Very low outgassing. Highest performance polymer for wear and friction, but at a premium cost. | 300 | 1.75 | 30 | Ultimate performance, highest cost polymer. |

| Acetal (POM - Polyoxymethylene) | Copolymer (e.g., Tecaform™, Celcon®) | Excellent dimensional stability, low moisture absorption, good lubricity, and high stiffness. Often used as the bearing surface in pre-lubricated composites like DX®. | 100 | 0.22 | 18 | Good for wet environments where nylon fails. |

| UHMW-PE (Ultra-High Molecular Weight Polyethylene) | Unfilled | Excellent for abrasion resistance in slurry services. Low coefficient of friction. Limited by very low temperature and load capacity. | 80 | 0.10 | 5 | Typically used as a liner, not a discrete bushing. |

|

¹ Max Temperature is for intermittent service. Continuous service temperature is typically 15-20% lower. All properties are highly dependent on operating conditions (mating surface, lubrication, environment). Values provided are for comparison under dry, ambient conditions and should be used as a guide. Consult manufacturer data for specific applications. ² Estimated values based on engineering principles and comparative analysis between unfilled and filled grades. Official manufacturer data for specific PV limits can vary. |

||||||

2.3 Composite Bearing Materials

Composite bearings combine the properties of different materials (metals, polymers, fibers) to create a superior bearing structure. They offer the high load capacity of metals with the self-lubricating properties of polymers, representing a best-of-both-worlds solution for many applications.

| Trade Name / Type | Manufacturer(s) | Composition & Structure | Key Characteristics | Max Temp (°C) | PV Limit (MPa·m/s) | Load Capacity (MPa, Dynamic) |

|---|---|---|---|---|---|---|

| DU® / Metal-Polymer | GGB, others | Steel Backing + Sintered Bronze Interlayer + PTFE/Lead Overlay. The original high-performance dry bearing. | Excellent dry friction and wear. High load capacity. Requires non-corrosive service due to bronze/steel. | 280 | 1.8 | 140 |

| DX® / Pre-lubricated | GGB, others | Steel Backing + Sintered Bronze Interlayer + Acetal (POM) Polymer Overlay with grease pockets. | Designed for marginally lubricated or grease-lubricated applications. Low friction with minimal lubrication. | 130 | 1.4 | 140 |

| GAR-MAX® / Fiber-Wound | GGB | Glass Fiber & PTFE liner, wound on a fiberglass/epoxy resin backing. High load, self-lubricating. | Extremely high load capacity. Excellent for high-vibration and misalignment. Good chemical resistance. | 165 | 0.9 | 210 |

| iglidur® Materials | igus | Homogeneous blends of base polymers, solid lubricants, and reinforcing fibers. Dozens of specialized grades. | Each grade is optimized for a specific purpose (e.g., high temp, chemical resistance, low cost). Self-lubricating. | 250 (iglidur® X) | 1.32 (iglidur® X)² | 100 (iglidur® X) |

| PolyLube® / Fiber-Wound | Polygon Company | Custom-woven fabric liners (PTFE, polyester) with high-strength filament-wound fiberglass and epoxy/vinylester resin backing. | Very high load capacity. Custom engineered for specific applications, including high-corrosion and dielectric needs. | 150 | 1.0² | 205 |

| CJ® / Composite | TriStar Plastics | Woven PTFE and other durable fiber liner bonded to a fiberglass/epoxy backing. Designed for low friction and extended wear. | Excellent for high-load, low-speed oscillating movements common in valves. Dimensionally stable and non-corrosive. | 135 | 0.75² | 207 |

|

¹ Values provided are for representative high-performance grades from each manufacturer. Specific properties vary significantly across the product range. Always consult the manufacturer’s engineering manual for the specific product grade being considered. ² PV Limit and Load Capacity are highly dependent on the specific grade, operating conditions, and mating surface. These values are estimates for comparison and represent high-performance, general-purpose grades under dry running conditions. |

||||||

2.4 Carbon/Graphite Bearing Materials

Carbon/Graphite is a self-lubricating material ideal for high-temperature applications where plastics and elastomers would fail. It is chemically inert in most environments but can be brittle. Its properties are tailored through impregnation with resins or metals.

| Material Type | Impregnant / Filler | Key Characteristics & Applications | Max Temp (°C, Oxidizing)¹ | Compressive Strength (MPa) | Notes |

|---|---|---|---|---|---|

| Resin-Bonded Carbon | Phenolic/Epoxy Resin | General-purpose grade. Resin fills porosity, increasing strength and fluid compatibility. Lowest cost carbon material. | 175 | 180 | Not for strong oxidizing agents or caustics. |

| Metal-Impregnated Carbon | Antimony (Sb) | The most common metal-impregnated grade. Antimony improves strength, thermal conductivity, and wear resistance. Excellent for dry-running applications. | 350 | 240 | Excellent "all-around" high-performance carbon. |

| Metal-Impregnated Carbon | Babbitt | Babbitt impregnation provides excellent lubricity for applications with marginal or fluid lubrication (e.g., pumps, turbines). | 150 | 195 | Lower temperature limit due to Babbitt's melting point. |

| Metal-Impregnated Carbon | Copper (Cu) | Copper impregnation greatly increases thermal conductivity and strength. Used in applications requiring rapid heat dissipation. | 350 | 260 | Higher strength and thermal performance than Antimony. |

| Oxidation-Resistant Carbon | Phosphate Salts | Contains chemical inhibitors that dramatically slow the rate of carbon oxidation at elevated temperatures, extending service life. | 550 | 200 | Essential for bearings in hot air or exhaust gas service. |

|

¹ Maximum temperature in an oxidizing atmosphere (e.g., air). In inert or reducing atmospheres, carbon/graphite materials can be used at much higher temperatures (>1500°C). The limiting factor is the oxidation of the carbon base. |

|||||

3. Engineering Standards & Cross-References

Specifying bearing materials requires a deep understanding of international standards. A material designation (e.g., ASTM C95400) provides a precise, universally understood definition of its chemical composition and minimum mechanical properties. This section provides an overview and cross-references for key metallic bearing materials.

3.1 Overview of Key Standards Organizations

ASTM International

- Region: USA (Globally recognized)

- Governs: Material specifications, test methods.

- Key Specs: ASTM B505/B22 (Bronze Alloys), ASTM A276 (Stainless Steel Bars), ASTM A479 (Stainless Steel Bars for Boilers/PV).

EN (European Norm)

- Region: European Union

- Governs: Harmonized standards across EU member states.

- Key Specs: EN 1982, EN 10283, EN 10088.

DIN (Deutsches Institut für Normung)

- Region: Germany (Widely used)

- Governs: German national standards.

- Key Specs: DIN 1705, DIN 1714. *Note: Many DIN standards are now superseded by EN standards.*

JIS (Japanese Industrial Standards)

- Region: Japan

- Governs: Japanese industrial activities.

- Key Specs: JIS H 5120, JIS G 4303.

| Alloy Description | UNS (ASTM) | EN (Number) | EN (Symbol) | DIN (Superseded) | JIS | BS (Superseded) | GOST (RU) | GB/T (CN) |

|---|---|---|---|---|---|---|---|---|

| Tin Bronzes | ||||||||

| Leaded Tin Bronze (SAE 660) | C93200 | CC491K | CuSn5Pb5Zn5-C | 1705: Rg 5 | H5120: CAC406 | 1400: LG2 | БрО5Ц5С5 | ZCuPb5Sn5Zn5 |

| High-Leaded Tin Bronze | C93700 | CC495K | CuSn10Pb10-C | 1705: G-CuPb10Sn | H5120: CAC603 | 1400: LB2 | БрО10С10 | ZCuPb10Sn10 |

| Tin Bronze (Navy G) | C90500 | CC481K | CuSn10Zn2-C | 1705: G-CuSn10Zn | H5120: CAC402 | 1400: G1 | БрО10Ф1 | ZCuSn10Zn2 |

| Aluminum & Manganese Bronzes | ||||||||

| Aluminum Bronze | C95400 | CC333G | CuAl10Fe5Ni5-C | 1714: G-CuAl10Ni | H5120: CAC703 | 1400: AB2 | БрА9Ж3Л | QAl9-4 |

| Nickel Aluminum Bronze | C95500 | CC333G | CuAl10Fe5Ni5-C | 1714: G-CuAl10Ni | H5120: CAC703 | 1400: AB2 | ||

| Manganese Bronze (High Strength) | C86300 | N/A | (Special High-Tensile Brass) | 1709: G-CuZn25Al5 | H5120: HBsC 4 | 1400: HTB3 | ||

|

Disclaimer: This table is for informational purposes only. An exact chemical or mechanical match may not exist between standards. The listed grades are considered functionally equivalent in many applications, but the relevant standard must always be consulted for official specifications, especially for critical projects. "Superseded" indicates that the national standard (e.g., DIN, BS) has been officially replaced by the harmonized EN standard, but the old designation is often still found on drawings and in industry parlance. |

||||||||

| Alloy Description | UNS | EN (Number) | EN (Symbol) | DIN (Designation) | JIS | GOST (RU) | GB/T (CN) |

|---|---|---|---|---|---|---|---|

| Stainless Steel 410 | S41000 | 1.4006 | X12Cr13 | X12Cr13 | SUS 410 | 12Х13 | 1Cr13 |

| Stainless Steel 17-4PH | S17400 | 1.4542 | X5CrNiCuNb16-4 | X5CrNiCuNb16-4 | SUS 630 | 07Х16Н4Д2Б | 0Cr17Ni4Cu4Nb |

| Nitronic™ 60 | S21800 | 1.3964 | X2CrNiMnMoNNb21-16-5-3 | (Proprietary) | (Proprietary) | (Consult) | (Consult) |

| Duplex Steel 2205 | S32205 / S31803 | 1.4462 | X2CrNiMoN22-5-3 | X2CrNiMoN22-5-3 | SUS 329J3L | 03Х22Н6М2 | 022Cr22Ni5Mo3N |

| Monel K500 | N05500 | 2.4375 | NiCu30Al | NiCu30Al | NCF 500 | НМЖМц 28-2.5-1.5 | (Consult) |

3.4 Key Manufacturer Materials

Leading bearing manufacturers offer a vast portfolio of proprietary materials, each engineered for specific performance characteristics. This section provides an overview of representative high-performance materials from industry leaders GGB and igus, illustrating the range of available solutions.

GGB (Garlock Bearings)

Pioneers in self-lubricating bearings, GGB's portfolio is a cornerstone of valve design.

- DU®: The original metal-polymer bearing. A steel backing with a sintered bronze interlayer impregnated and overlaid with a PTFE/lead mixture. The benchmark for high-PV, dry-running applications.

- DX®: A marginally-lubricated bearing with a steel/bronze structure and an acetal overlay featuring grease indents. Ideal for applications with intermittent lubrication.

- GAR-MAX®: High-strength, filament-wound fiberglass backing with a PTFE liner. Offers exceptional high-load capability and excellent resistance to shock and misalignment.

- HSG (High-Strength GAR-MAX®): Enhanced load capacity for the most demanding structural pivot points in large valves and dampers.

igus® iglidur®

Specializes in injection-molded, all-polymer bearings made from proprietary tribologically-optimized compounds.

- iglidur® X: High-temperature and high-chemical resistance. Combines a temperature range up to 250°C with broad compatibility, making it a versatile choice for process valves.

- iglidur® G: The "universal" material. A cost-effective, all-around performer with good wear rates and low friction, suitable for general-purpose butterfly valves.

- iglidur® Z: Designed for very high loads and temperatures, with extremely low wear rates, often used in applications where metallic bearings would traditionally be specified.

- iglidur® H1: Engineered for long life in highly corrosive chemical environments, offering superior performance to standard plastics.

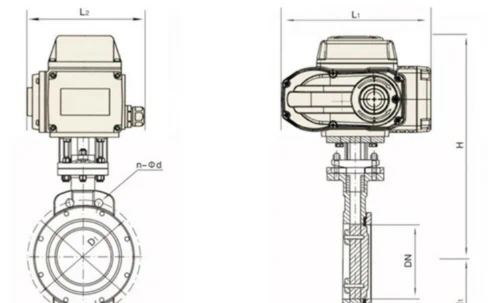

4. Design & Installation Considerations

Proper design and installation are as crucial as material selection. Failures often originate from incorrect clearances, poor surface finishes, or improper installation techniques rather than the bearing material itself.

Key Engineering Principles

- Clearances: The running clearance between the stem and the bearing is critical. It must be tight enough to ensure alignment but loose enough to accommodate thermal expansion, fluid swell (in polymers), and manufacturing tolerances without seizure. Always consult manufacturer data for recommended press-fit and running clearances.

- Mating Surface Finish: The stem's surface finish directly impacts friction and wear. For polymer and composite bearings, a smooth, non-directional finish (Ra 0.2-0.4 μm / 8-16 μin) is ideal. For metallic bearings, a hardened and ground stem is essential to prevent galling.

- Edge Loading: Stem deflection or housing misalignment can cause the load to concentrate on the edge of the bearing, leading to rapid failure. Self-aligning bearings (like GAR-MAX) or incorporating lead-in chamfers can mitigate this risk.

- Press-Fit Installation: Bushings are typically installed with a press-fit into the valve body. It is essential to use a proper mandrel that applies force only to the outer ring of the bushing. Pressing on the bearing's inner bore will damage the running surface. The housing bore must be clean, correctly sized, and free of burrs.

5. FAQ & Engineering Glossary

Addressing common questions and defining key terms related to butterfly valve bearing technology.

What is "galling" and how do I prevent it?

Galling is a form of severe adhesive wear that occurs between two sliding metal surfaces under heavy load. The materials effectively "cold-weld" together, causing surface tearing and eventual seizure. It is most common between similar or identical metals, especially austenitic stainless steels. Prevention is key:

1. Material Dissimilarity: Ensure the stem and bearing have a significant hardness differential (e.g., hardened 17-4PH stem against a soft C93200 bronze bearing).

2. Anti-Galling Alloys: Use materials specifically designed to resist galling, such as Nitronic 60 for the stem or a Stellite overlay.

3. Self-Lubricating Bearings: Use non-metallic bearings (PTFE, PEEK, Composites) to eliminate metal-to-metal contact entirely.

Why is a high PV Limit important?

The PV Limit (Pressure x Velocity) is the single most important parameter for self-lubricating bearings. It defines the maximum energy input the bearing can tolerate before frictional heat generation exceeds its ability to dissipate that heat. Exceeding the PV limit causes the bearing's polymer surface to soften, melt, and fail rapidly. A high PV limit indicates a robust bearing capable of handling high loads (P) at high speeds (V), even though valve operation is typically low-speed (low V). In valves, high pressure (P) from fluid dynamics dominates the PV calculation, so a high limit is a direct indicator of high-load performance.

Can I use a metal bearing in a dry gas service?

It is highly discouraged. Most metallic bearings (like bronze) rely on some form of lubrication to function without galling or excessive wear. This is often provided by the process fluid itself (e.g., water, oil). In a completely dry service (like nitrogen or dry air), there is no lubricating film. This will lead to high friction, potential seizure, and rapid wear. For dry services, self-lubricating materials like RPTFE, PEEK, composites (DU), or carbon/graphite are the mandatory and correct engineering choice.

What is the difference between a bearing and a bushing?

In the context of valves, the terms are used almost interchangeably. Technically, a "bushing" is a specific type of plain bearing: a one-piece, sleeve-like component that provides a low-friction surface for rotary or linear motion. The term "bearing" is more general and can encompass more complex assemblies (like roller bearings). For butterfly valves, the stem support is almost always a bushing, but it is commonly referred to as a "stem bearing" or "shaft bearing."

Glossary of Terms

- Cold Flow (Creep): The tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. A significant issue for unfilled PTFE.

- Embeddability: The ability of a bearing material to absorb or embed small foreign particles, preventing them from scoring the shaft. A key feature of leaded bronzes and softer polymers.

- PREN (Pitting Resistance Equivalent Number): A numerical value for a stainless steel's resistance to pitting corrosion, calculated from its chemical composition. Higher is better.

- Stiction (Static Friction): The friction that must be overcome to initiate motion between two surfaces. In valves, high stiction leads to high "breakaway" torque.

- Tribology: The science and engineering of interacting surfaces in relative motion, including the study of friction, wear, and lubrication.

Need Help Selecting the Right Bearing?

Our engineers can help you specify the perfect material for your valve's service conditions.

JRVAL

JRVAL Aug 13 2025

Aug 13 2025