Mitigating Mechanical Failure and Fugitive Emissions in a Specialty Chemicals Plant

This case study details how a Gulf Coast specialty chemicals facility resolved persistent valve failures in a mixed acid transfer line, moving from a high-risk, reactive maintenance cycle to a predictable, low-TCO operation by implementing our material-verified high-performance butterfly valves.

See TCO AnalysisThe Challenge: When "Low-Cost" Valves Create Unacceptable Risk

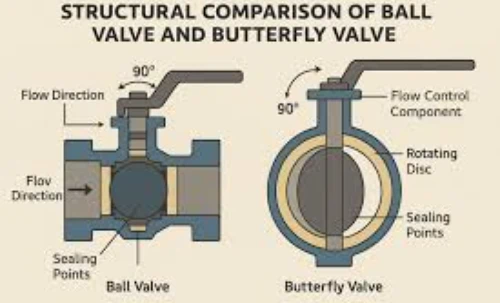

The reliability team at a specialty chemicals facility was battling recurring failures on a critical transfer line. The line handled a 30% sulfuric acid solution with trace organic solvents at 80°C and 10 bar. The valves were located near reciprocating pumps, subjecting them to constant, low-amplitude, high-frequency vibration (~45-60 Hz).

Their incumbent valves were commodity-grade, pinned-disc butterfly valves sourced from a general import supplier. While the initial unit cost was low, the operational reality was a constant state of emergency, with an average Mean Time Between Failures (MTBF) of just 90 days.

Key Technical & Financial Issues:

- Mechanical Failure under Vibration: The primary failure mode was the shearing of the taper pins connecting the stem to the disc. This would cause a complete loss of control, leaving the valve stuck in a partially open state and triggering an emergency shutdown.

- Fugitive Emissions and Sealing Integrity: The existing EPDM seats would swell and degrade in the chemical mix, leading to fugitive emissions exceeding their internal limit of 500 ppm. Furthermore, the unidirectional seal was a safety hazard, unable to prevent backflow contamination during maintenance isolation.

- Deceptive Total Cost of Ownership (TCO): Each failure event cost an estimated \$12,000 in lost production and maintenance labor, completely eclipsing the low initial cost of the valve. The procurement team's focus on unit price was inadvertently driving up operational expenditure (OPEX).

The Solution: An Engineered Approach to Reliability and Value

We proposed our High-Performance Butterfly Valve as a direct replacement. Our approach was not to compete on the lowest unit price, but to deliver a verifiable, engineered solution that would fundamentally lower the plant's TCO and operational risk.

Immunity to Vibration: The Pinless Advantage

Our Pinless Design with a key/square shaft connection directly addressed the root cause of failure. This robust design eliminates the stress concentration points inherent in pins. Cycle testing under simulated 60 Hz vibration shows our connection maintains >99.8% torque transmission integrity after 100,000 cycles, preventing the control loss that plagued the previous valves.

Foundry-First Integrity: Guaranteed Material DNA

We know that for corrosive service, material is everything. Unlike a source factory that may use recycled or untraceable steel, our process is built on Foundry-First Metallurgy. We provided full MTC 3.1 certificates and Positive Material Identification (PMI) reports for every valve, verifying the ASTM A351 CF8M bodies and discs contained the required >2.0% Molybdenum content essential for sulfuric acid resistance.

Engineered Sealing: ISO 15848 Compliance

The combination of a chemically resistant FKM seat and a spherically machined disc edge provides bubble-tight, bi-directional shutoff. This design is certified to ISO 15848-1 Class CH, guaranteeing fugitive emissions are kept below 100 ppm, well within the plant's safety and environmental targets.

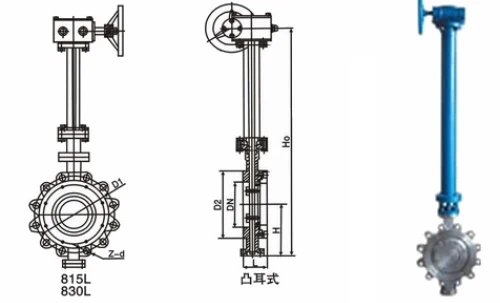

Drop-In Replacement & Long-Term Support

With our 11 CNC centers machining components to standardized dimensions (e.g., valve body concentricity to ≤ 0.05mm), our valves served as a drop-in replacement, requiring no pipe modifications. Our 20+ years of design validation ensure fit and function. We backed this with a comprehensive 2-year warranty, including free replacement of wear parts like seats and seals.

OUR 11 PRECISION CNC MACHINING CENTERS

CNC Center 1

CNC Center 2

CNC Center 3

CNC Center 4

CNC Center 5

CNC Center 6

CNC Center 7

CNC Center 8

CNC Center 9

CNC Center 10

CNC Center 11

Results: Tangible ROI & De-Risked Operations

After 24 months in service, the performance of the 32 installed valves provided clear, quantifiable data, validating the shift from a price-based to a value-based procurement strategy.

>800 Days

Mean Time Between Failures (vs. 90 days prior)

<50 ppm

Average Fugitive Emissions (vs. >500 ppm prior)

42%

Projected 3-Year TCO Reduction

3-Year Total Cost of Ownership (TCO) Analysis (Per Valve)

| Cost Factor | Previous Commodity Valve | Our High-Performance Valve |

|---|---|---|

| Initial Unit Cost (CAPEX) | \$420 | \$550 |

| Expected Lifetime | ~1 Year | >5 Years |

| Maintenance Events (3 Years) | 4 (3 replacements, 1 repair) | 1 (preventive seat change) |

| Maintenance & Labor Cost | 4 events x \$800 = \$3,200 | 1 event x \$400 = \$400 |

| Downtime Cost (3 failure events) | 3 events x \$12,000 = \$36,000 | \$0 (preventive maintenance) |

| Total 3-Year TCO | \$39,620 | \$950 (Valve) + Warranty Parts |

"The pinless design was a game-changer for our pump-adjacent lines. But the real win was the TCO analysis we could build. We proved to management that paying 30% more upfront would save us a fortune in downtime. The material traceability and ISO 15848 compliance sealed the deal for our EHS team. We're not buying the cheapest part anymore; we're buying predictable uptime."

Reliability Engineer, (Anonymous) Specialty Chemicals Plant

Partner with a Value-Driven Valve Expert

Your process reliability shouldn't be a gamble on unverified materials. Our engineered solutions are designed to deliver a superior return on investment by eliminating the hidden costs of failure.

Contact us to run a custom TCO analysis for your specific application and see how a smarter investment in valve technology can strengthen your bottom line.

Request a TCO Consultation

JRVAL

JRVAL Aug 18 2025

Aug 18 2025